Hollow tube flange composite beam provided with internal and external stiffening ribs

A technology of composite beams and flanges, applied in bridges, buildings, etc., can solve problems such as difficult compaction of filled concrete, difficult construction, complex connection structure of filled concrete pipe flanges, etc., to achieve superior heat insulation and fire protection capabilities, and improve Cross-section utilization and material saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

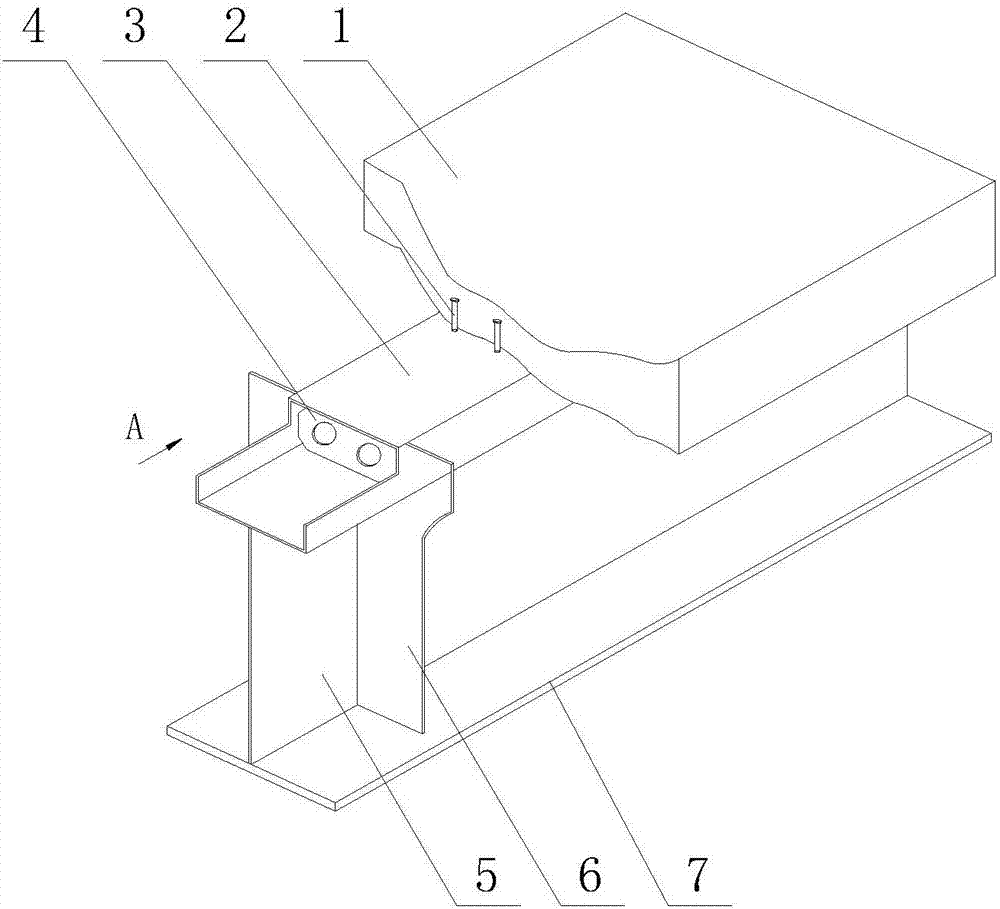

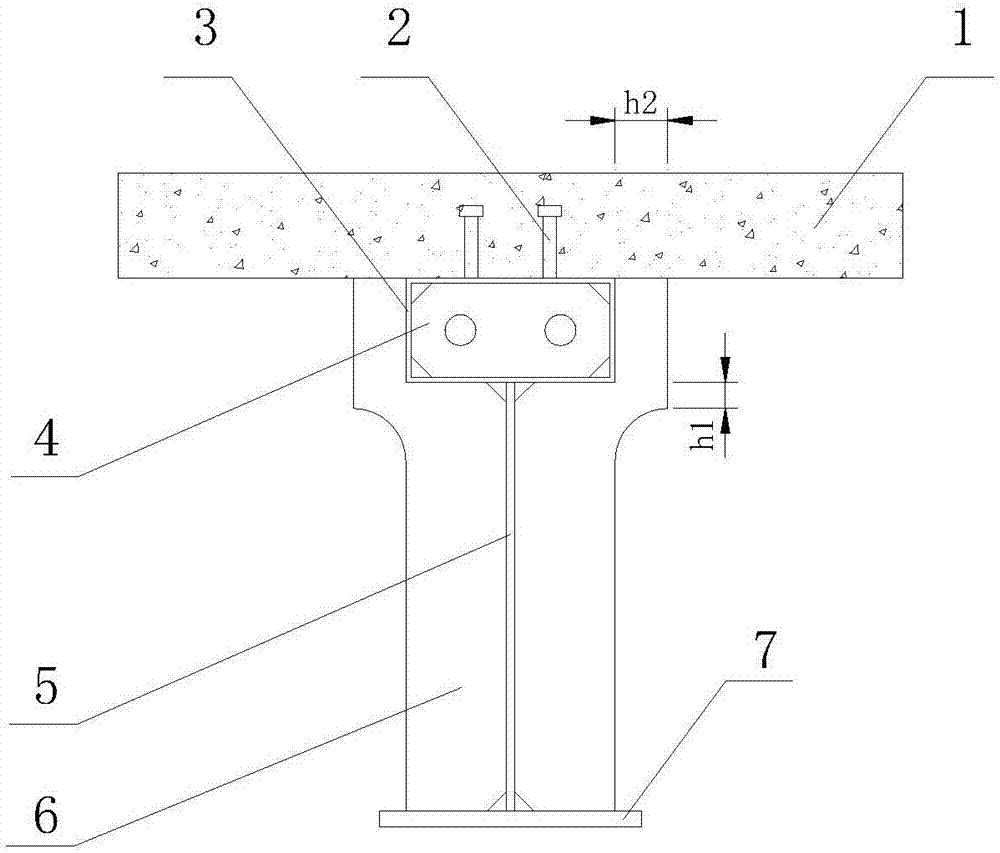

[0031] See figure 1 with figure 2 The inner-external stiffened hollow tube flange composite beam of this embodiment is composed of the top plate 1, the shear connector 2, the upper flange 3, the inner stiffener 4, the web 5, the outer stiffener 6 and the lower flange 7. constitute.

[0032] The lower flange 7 of this embodiment is a flange steel plate for ordinary steel bridges, that is, a rectangular steel plate with a length×width×height of 4300×200×12mm. The web 5 is welded to the middle of the lower flange 7. The lower flange 7 is vertical, the height of the web 5 is 328 mm, the thickness is 4 mm, and the length is equal to the length of the lower flange 7. An upper flange 3 is welded on the top of the web 5. The upper flange 3 of this embodiment is a rectangular hollow tubular structure, and is arranged parallel to the lower flange 7. Its length×width×height is 4300×160×80mm, and the wall thickness 4mm, two parallel shear connectors 2 are welded on the top of the upper fla...

Embodiment 2

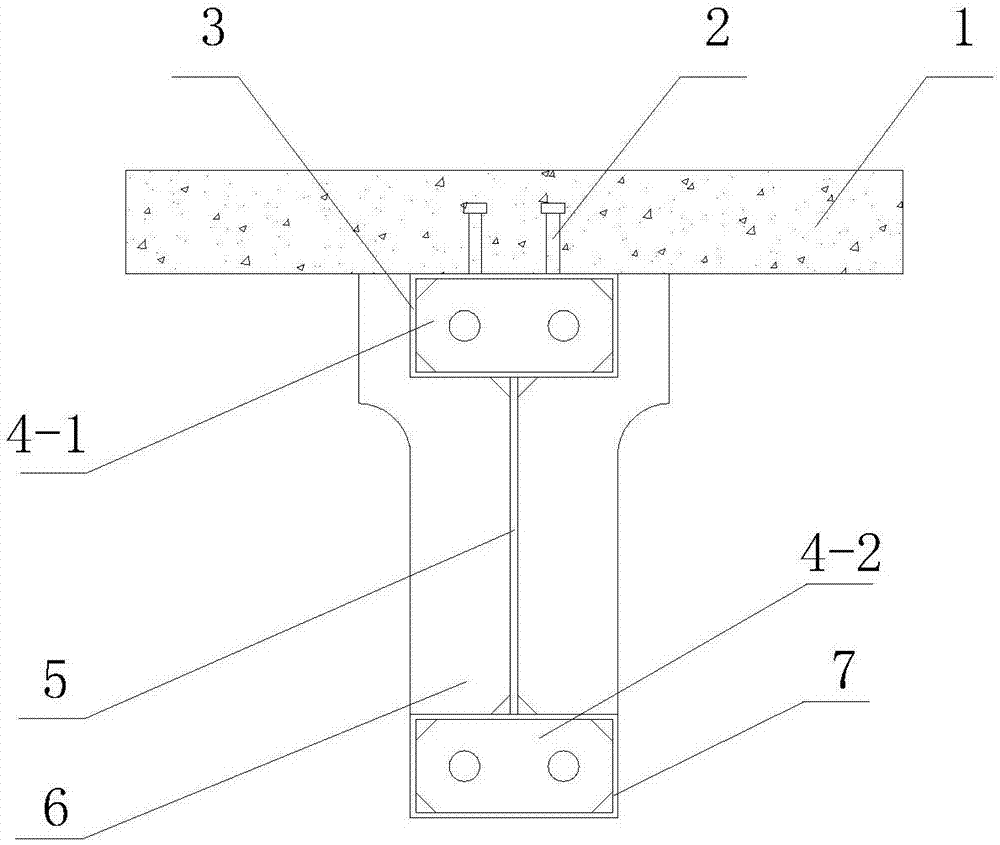

[0034] The upper flange 3 of this embodiment is a rectangular hollow tube structure, which is arranged in parallel with the lower flange 7. Its length×width×height is 1800×200×80mm, and the wall thickness is 4mm. Stiffener 4, the four top corners of the inner stiffener 4 are all processed into a chamfered structure, the chamfer is an isosceles triangle, the waist length is 1 / 5 of the side length of the upper flange 3, and the belly is welded in the middle of the lower flange 7. Plate 5, the height of the web 5 is 328mm, the thickness is 4mm, and the length is equal to the length of the lower flange 7. On the left and right sides of the web 5, there are welded vertical external stiffeners 6, and the upper section of the external stiffener 6 is connected with The lower sections are connected by arc sections, and the lateral width of the upper section is smaller than the width of the lower section, and the longitudinal distance between the highest point of the arc section and the l...

Embodiment 3

[0037] The upper flange 3 of this embodiment is a rectangular tubular structure, which is arranged in parallel with the lower flange 7. Its length×width×height is 60000×700×200mm, and the wall thickness is 18mm. The inner cavity of the upper flange 3 is welded with internal stiffeners. The four top corners of rib 4 and inner stiffener 4 are all processed into a chamfer structure, the chamfer is an isosceles triangle, the waist length is 9 / 40 of the side length of the upper flange 3, and the web is welded in the middle of the lower flange 7. 5. The height of the web 5 is 2500mm, the thickness is 20mm, and the length is equal to the length of the lower flange 7. On the left and right sides of the web 5, there are welded vertical external stiffeners 6, and the upper and lower sections of the external stiffeners 6 Are connected by arc segments, and the lateral width of the upper segment is smaller than the width of the lower segment, the longitudinal distance between the highest poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com