Duration test device of automatic adjustment arm

A technology for automatically adjusting arms and testing devices, which is applied in the automotive field and can solve problems such as complicated operations, large brake drums, and uneconomical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

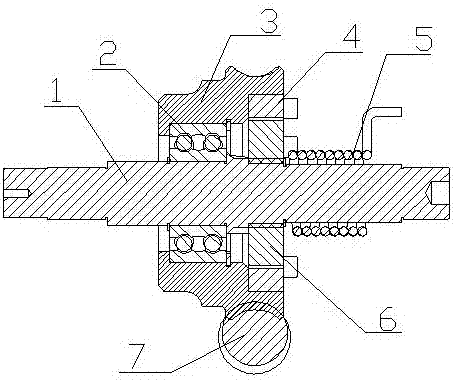

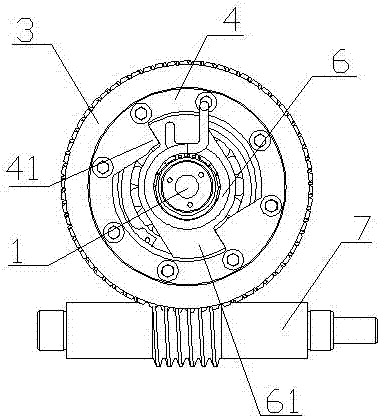

[0016] Such as figure 1 with figure 2 As shown, a kind of automatic adjustment arm durability test device comprises worm gear 3, worm screw 7, transmission wheel 6 and rotating shaft 1, and described worm gear 3 and worm screw 7 are meshed; When driving the wheel, the mechanism is self-locking, and the self-locking effect of the turbine 3 worm 7 mechanism is used to simulate the resistance torque during the braking process of the car. The transmission wheel 6 is sleeved on the rotating shaft 1 and has an interference fit with the rotating shaft 1. The rotating shaft 1 passes through the turbine 3 and is transmitted between the transmission wheel 6 and the turbine 3; The torsion spring 5 on the top, one end of the torsion spring 5 is fixedly connected with the transmission wheel 6, and the other end is a connecting end. During the test, the automatic adjustment arm is sleeved on the rotating shaft 1 and connected with the connection end of the torsion spring 5. When the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com