Damper for gas turbines

A gas turbine and damper technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as hindering dampers, and achieve the effect of extending operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

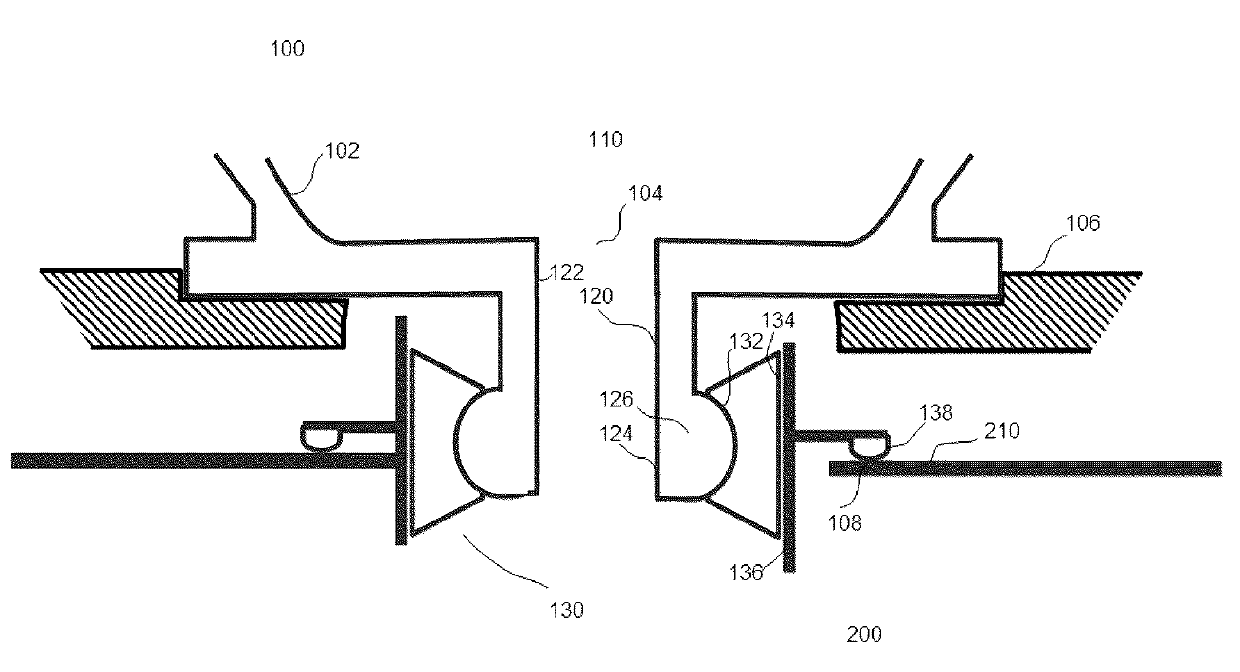

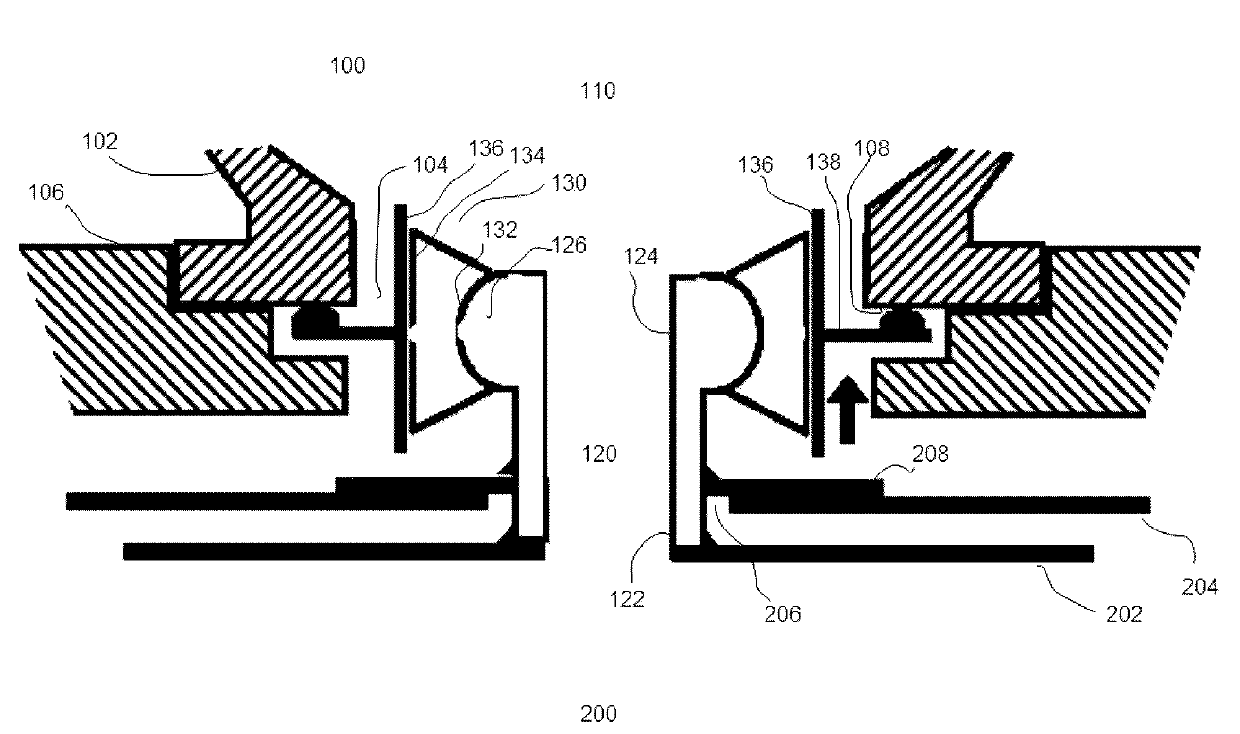

[0045] figure 1 A schematic cross-sectional view of a damper 100 with a portion of a combustor 200 of a gas turbine is shown according to an embodiment of the invention, with some portions cut away for clarity. The damper 100 includes a resonant cavity 110 having a box shape or a cylindrical shape as defined by the peripheral wall 102 and the inlet 104 . Such as figure 1 As shown, the main part of the resonant cavity 110 is cut away, because this will not hinder a complete and complete understanding of the technical solution of the present invention. Also, for clarity and conciseness, figure 1 Only those parts of the combustion chamber 200 that are closely relevant to the invention are shown. Resonant cavity 110 consists of figure 1 Fasteners, not shown, are hermetically attached to the structure 106 of the combustion chamber 200 . In an exemplary embodiment of the invention, the structure 106 of the combustor 200 may be a shell of the combustor 200 . Those skilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com