Method and apparatus for increasing programming yield

A technology of yield rate and camera module, which is applied in the direction of program control device, software deployment, program loading/starting, etc., can solve the problem that the camera module cannot continue to be used, so as to improve the burning yield rate, improve the finished product yield rate, The effect of improving the yield rate of programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

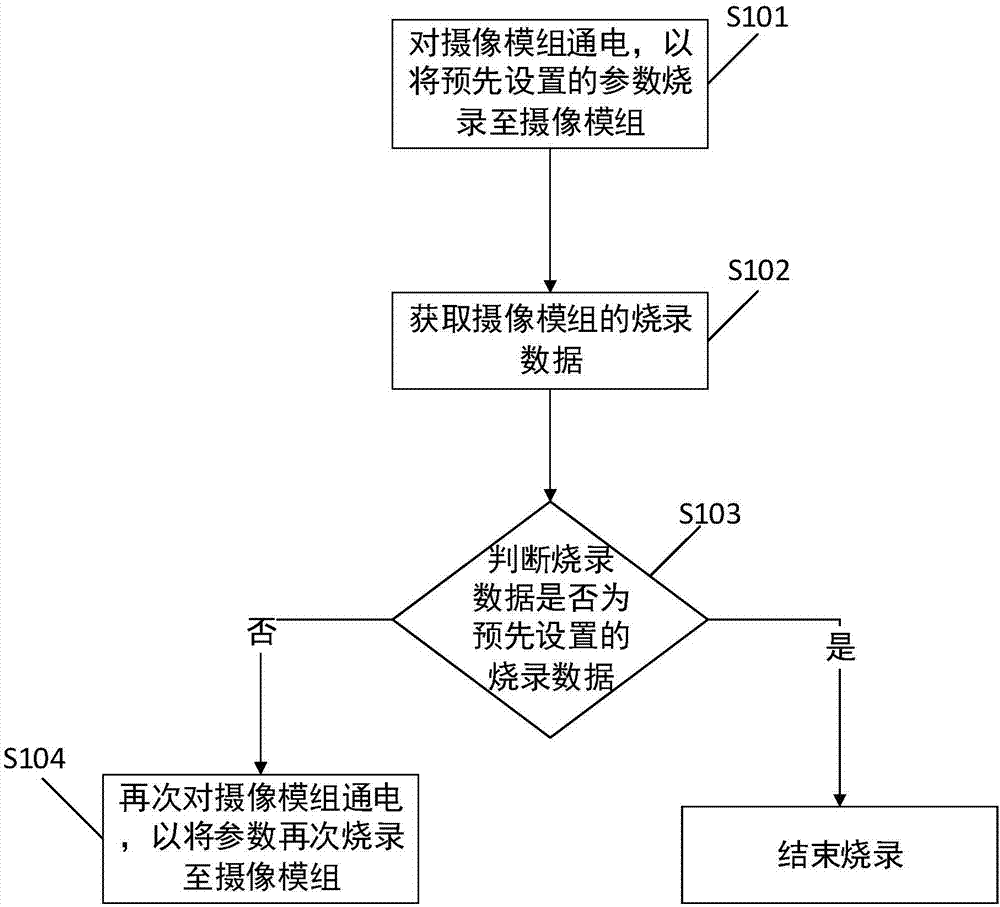

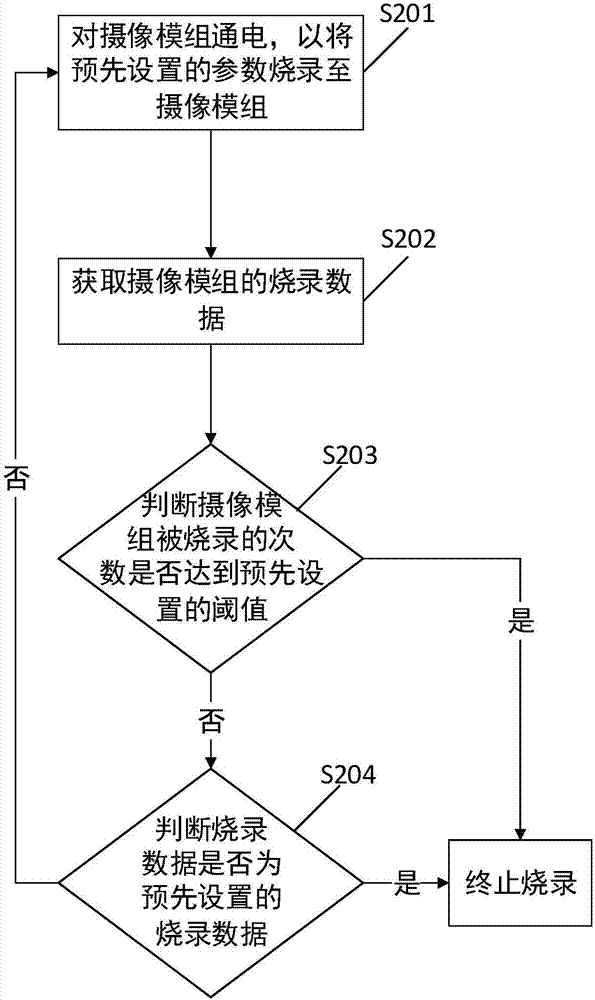

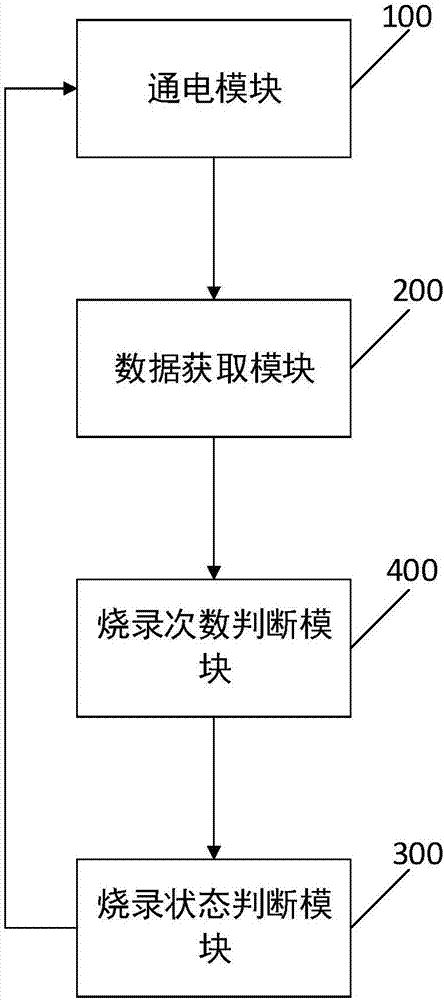

[0041] The core of the present invention is to provide a method for improving the programming yield. In the prior art, the camera module is usually only burned once. If the burning is successful, the camera module can continue to be used. If it is unsuccessful, the camera module cannot continue to be used. During the burning process, accidents often occur, such as unstable power supply of the burning equipment, etc., which will cause the failure of burning, limit the yield of burning, and thus limit the yield of camera module shipments.

[0042] However, a method for improving the programming yield provided by the present invention can re-energize the failed camera module for burning, and improve the burning yield of the camera module through the method of secondary burning. Thereby, the yield rate of finished products of the camera module is further improved.

[0043] In order to enable those skilled in the art to better understand the solution of the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com