Production method and device of electric precipitator cathode lines

A technology of electrostatic precipitator and production equipment, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of low production output, poor quality consistency, and low overall production efficiency, and achieve the effects of high production efficiency, reduced investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

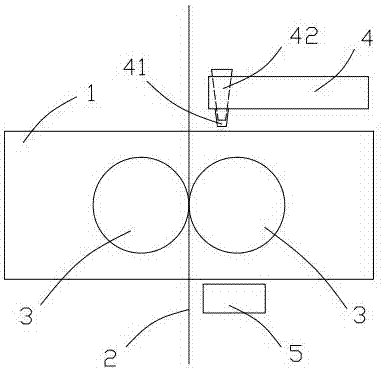

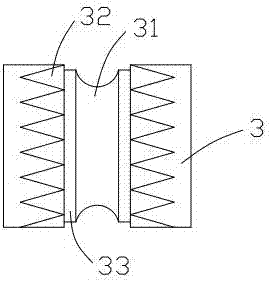

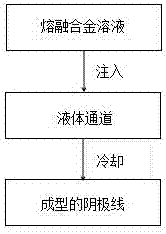

[0032] Such as Figure 1~2 As shown, a cathode wire production device for an electrostatic precipitator includes a production stand 1 and a steel core wire 2 vertically installed in the production stand. Two press rollers 3 are also arranged in the production stand 1, and the press roller 3 includes Cylindrical body, the cylindrical outer surface of the pressure roller 3 is provided with a groove 31 around the cylinder, along the two sides of the groove 31, there are tooth groove structures 32 connected with the groove, and the cylinders of the two pressure rollers 3 The outer surface of the shape is closely arranged and the positions of the two grooves 31 are aligned, the inner surfaces of the two grooves 31 are arranged symmetrically with respect to the steel core wire 2, and the positions of the tooth groove structures 32 of the two pressure rollers are corresponding.

[0033] The tooth portion of the tooth groove structure 32 may specifically be a zigzag tooth portion, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com