Belt redirection roller online repair device and method

A technology of redirecting rollers and belts, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of increasing the consumption of spare parts and expenses, reducing the service life of the redirecting rollers, scratching the belt, etc., and achieving convenient and fast online The effect of repairing, reducing work intensity and preventing belt deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

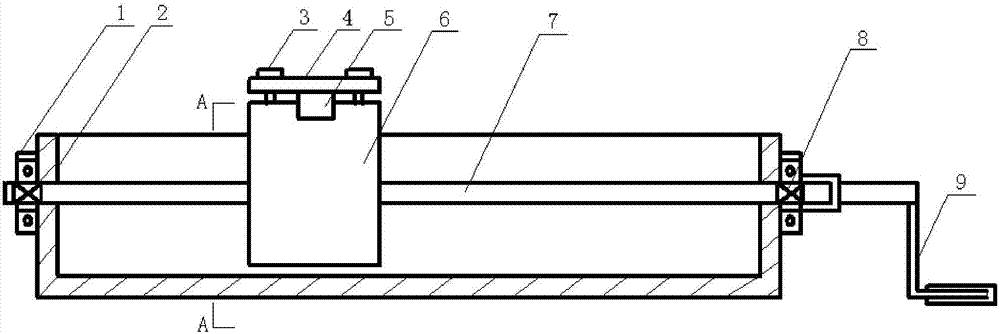

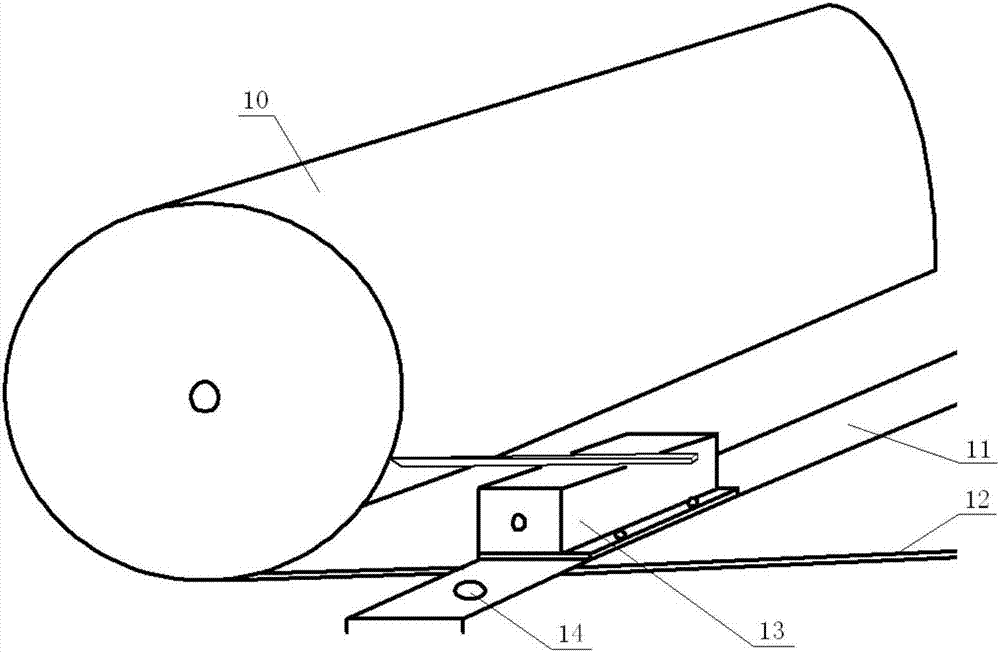

[0027] Depend on figure 1 , 2 It can be seen that the on-line repairing device for belt deflection rollers of the present invention includes a base 11 and a turning mechanism 13 . The base 11 is made of channel steel, and one side of the base 1 has two bolt holes 14 for fixing the turning mechanism 13 .

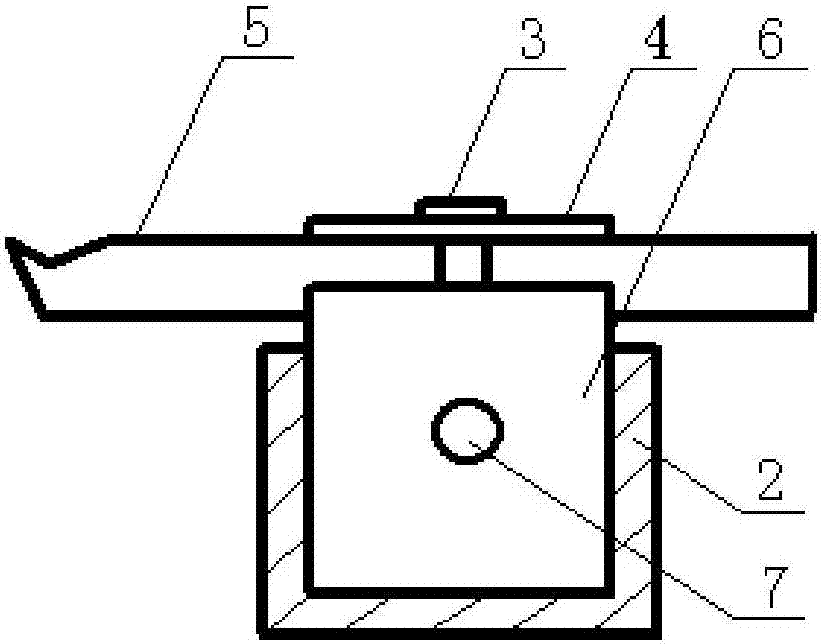

[0028] Turning mechanism 13 comprises frame 2, turning tool 5, transmission screw rod 7 and knife rest, and knife rest is made up of fixed bolt 3, pressing plate 4 and nut 6. Nut 6 is a square body of 30 * 50 * 60mm, along the nut 6 upper surface longitudinal processing has a through sipe, turning tool 5 is clamped in the sipe, and is fixed by pressing plate 4 and fixing bolt 3. Loosen the fixing bolt 3, and the turning tool 5 can slide back and forth in the knife groove to adjust the position of the turning tool 5. The frame 2 is a box-shaped body with a length of 450mm, a width of 55mm, a height of 65mm, and a wall thickness of 12mm. The two end walls of the frame 2 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com