Steel product piling platform

A technology for stacking and steel, applied in the field of stacking, can solve the problems of difficult processing of steel, inability to divide and process in real time, etc., and achieve the effects of easy stacking, wide applicability, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

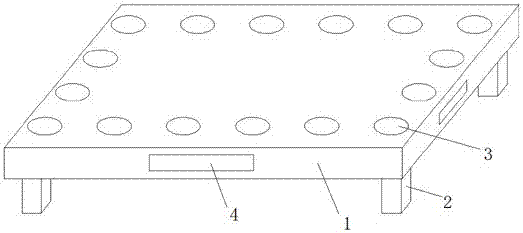

[0016] A steel stacking platform, the rectangular platform body 1 is provided with a number of slots 3 matching uprights, the bottom support foot 2 is a hydraulic foot with universal wheels, and the support foot 2 is provided with a pressure device.

[0017] A mercury level and a digital level are respectively arranged on the lateral side and the vertical side of the platform body 1 .

[0018] The readings of the pressure device and the digital level are displayed through the display screen 4 on the side of the table body 1 .

[0019] when using it:

[0020] According to the usage requirements, a number of uprights are inserted into the corresponding slots 3 of the table body 1 to intercept a certain carrying space of the table body 1 . Within the range space of the column, place the corresponding steel.

[0021] When placed, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com