scroll compressor

A scroll compressor and scroll technology, used in rotary piston machines, rotary piston engines, rotary piston pumps, etc., can solve problems such as reduced responsiveness, inability to respond properly, and a large number of parts , to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

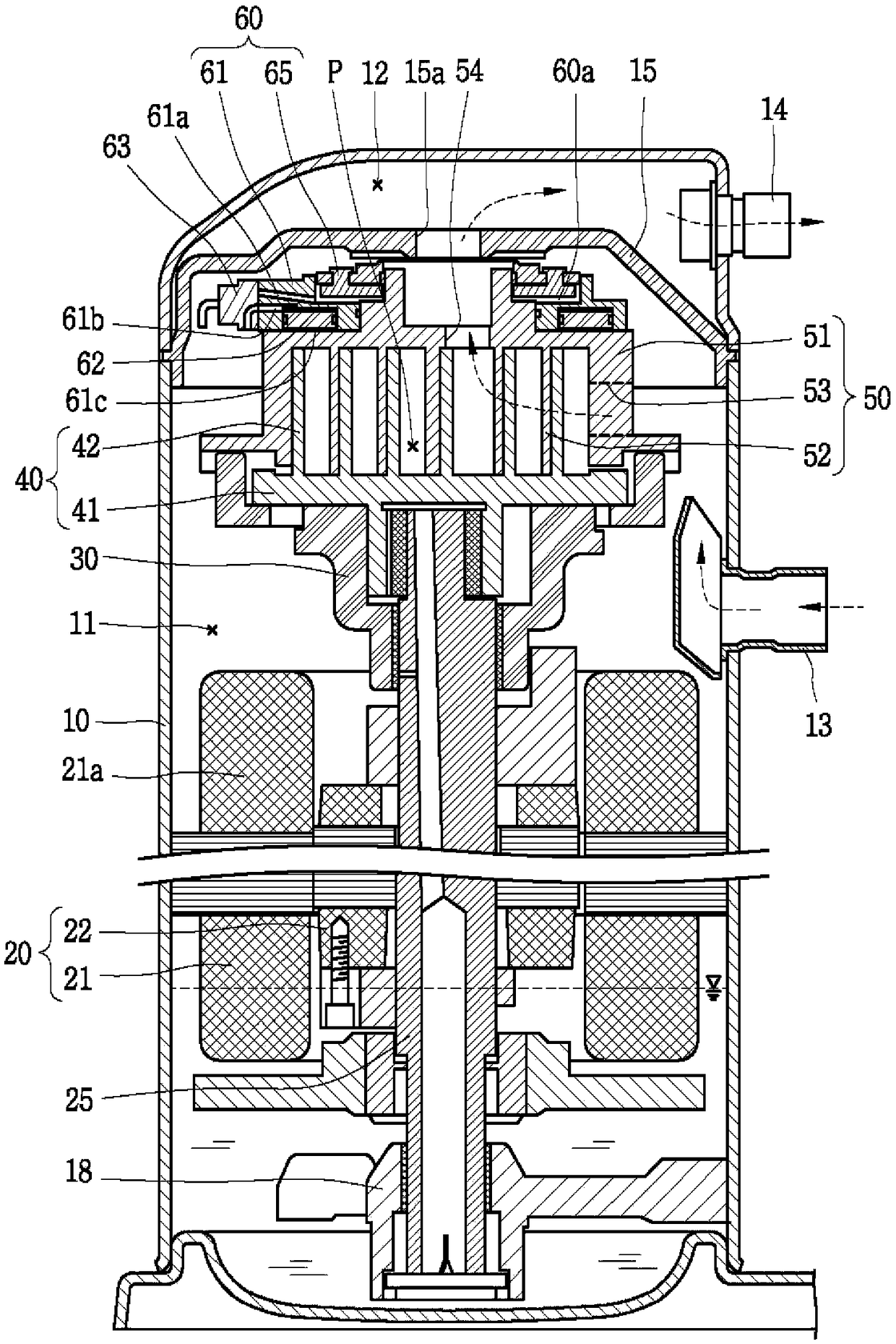

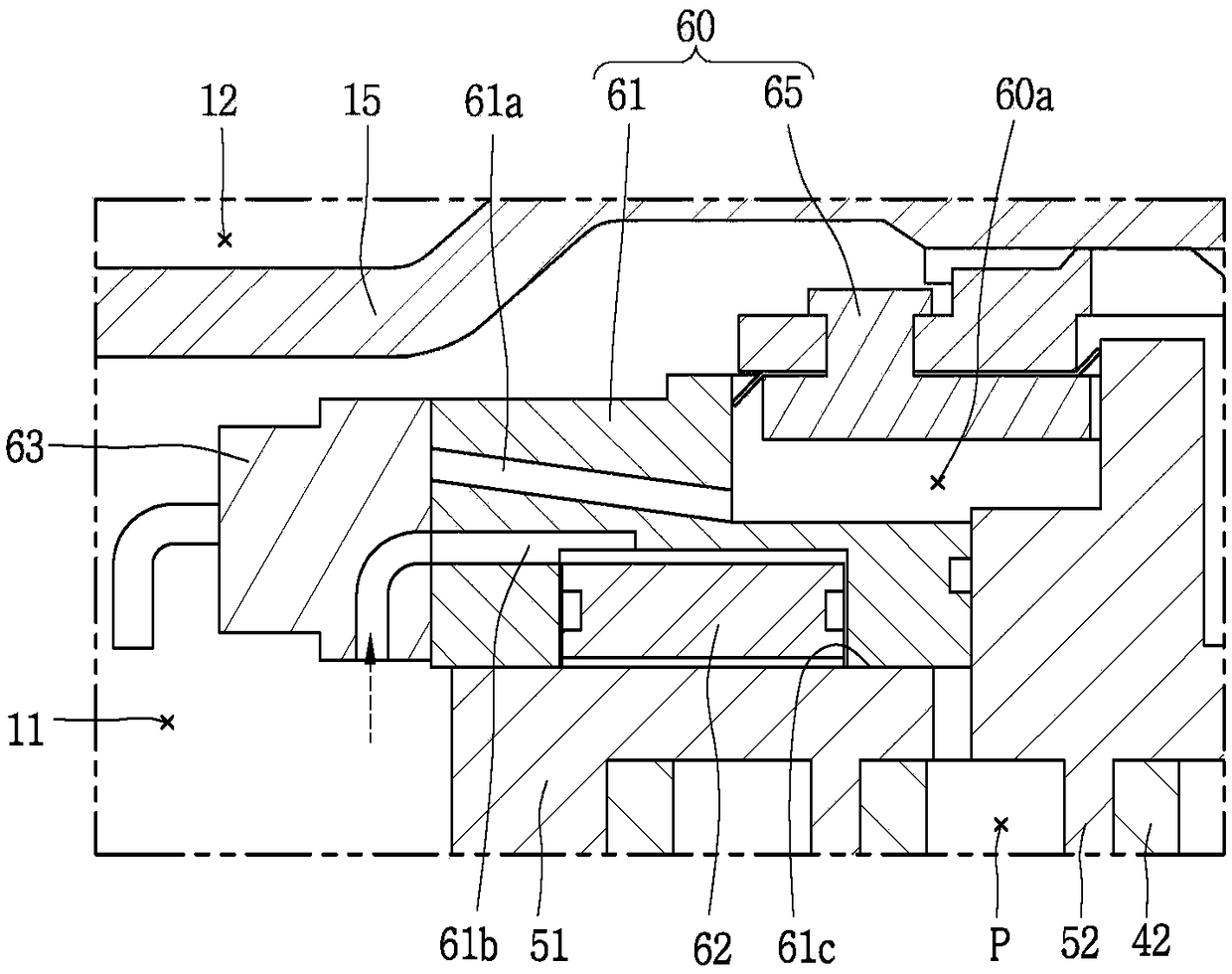

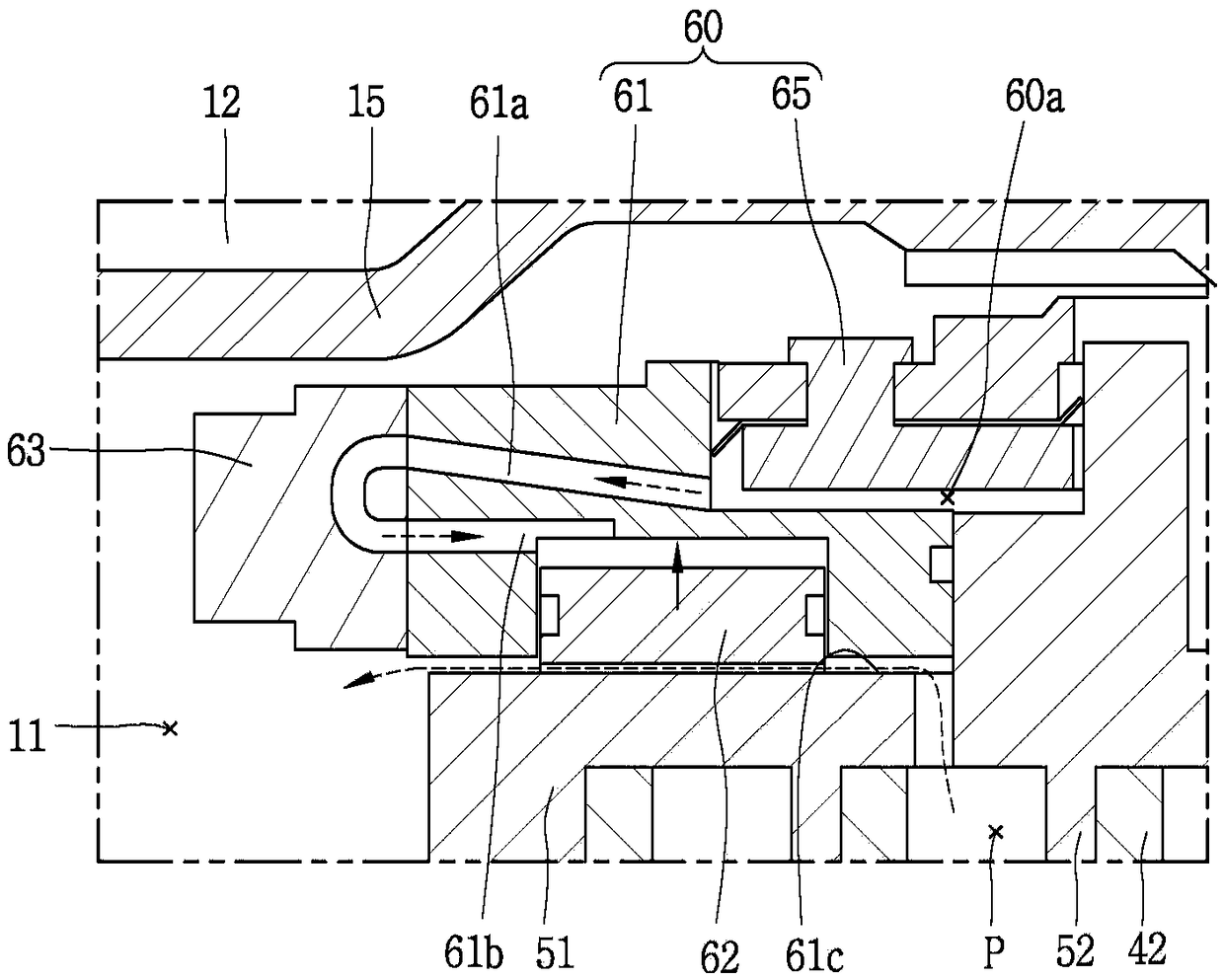

[0066] Hereinafter, an embodiment of the scroll compressor of the present invention will be described in detail with reference to the drawings.

[0067] image 3 It is a longitudinal sectional view showing a scroll compressor having a capacity variable device of the present invention, Figure 4 is showing image 3 A perspective view of the interior of a scroll compressor with a variable capacity device, Figure 5 will be image 3 An exploded perspective view of the capacity variable device of an embodiment of Figure 6 will be Figure 5 A perspective view showing the assembled and cutaway capacity variable device of an embodiment of the present invention.

[0068] refer to image 3 The sealed internal space of the casing 110 of the scroll compressor of this embodiment is separated into a low-pressure part as a suction space by a high-pressure and low-pressure separation plate 115 provided on the upper side of a non-orbiting scroll 150 described later. 111 and a high pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com