Three-way assembly variable joint

A combined and variable technology, applied in the field of pipe joints, to achieve a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

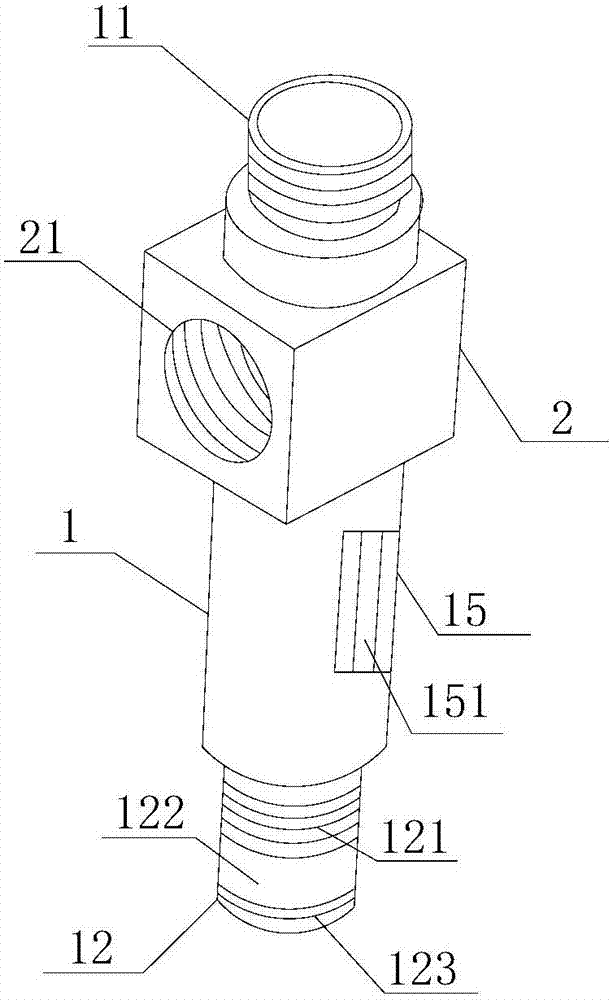

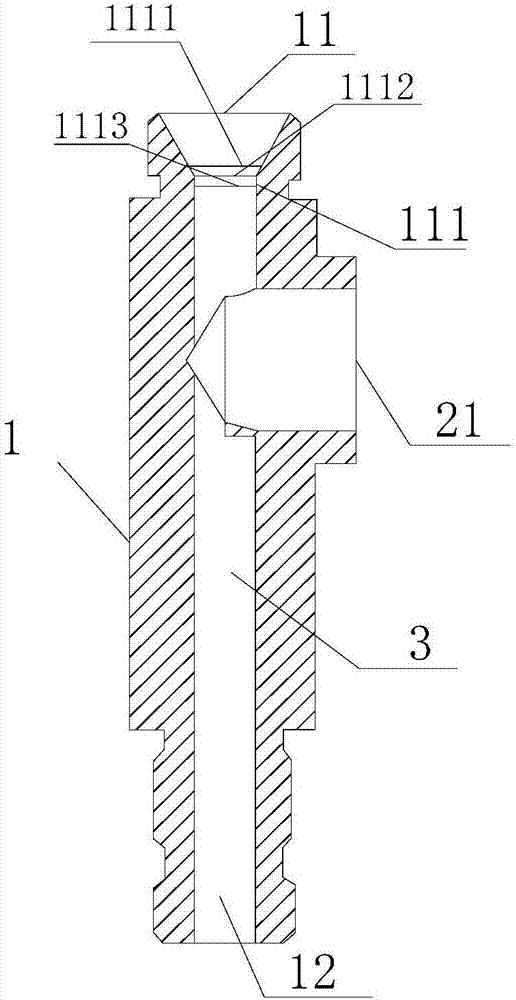

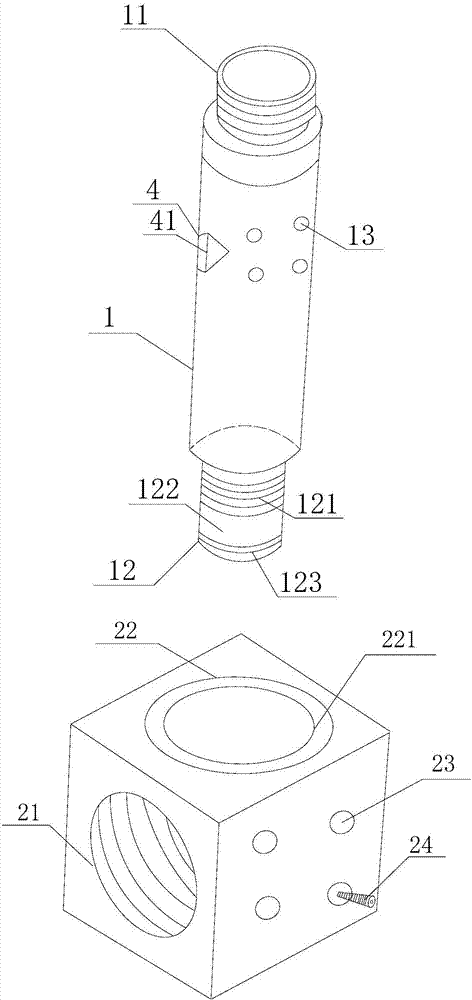

[0022] A third joint 21 is provided at the front end of the second connecting seat 2. The third joint 21 is a threaded joint. The third joint 21 communicates with the first connecting seat 1 to keep the stable use of the joint. Connecting holes 22 are opened at the end, and several locking holes 2 are opened on the left and right sides of the second connecting seat 2. When used as a three-way combination joint, the two connecting holes 22 are sleeved into the first connecting seat 1, so that The locking hole 23 corresponds to the position of the blind hole 13 of the first connecting seat 1, and the first connecting seat 1 is kept perpendicular to the second connecting seat 2, and then the bolt 24 is inserted into the locking hole 23 and the blind hole 13 to fix the second connecting seat. 2 seats are enough.

Embodiment 2

[0024] Since the third joint 21 communicates with the first connection seat 1, a fixing hole 4 is provided at the joint between the third joint 21 and the first connection seat 1. When using it as a straight-through joint, the second connection seat 2 needs to be disassembled and removed. The fixing hole 4 is closed to keep the tightness of the joint. A step 41 is set in the fixing hole 4 to delay the leakage of the medium, and then a tightening nut 14 is set on the first connecting seat 1, and the tightening nut 14 is placed on the fixing hole 4 , by arranging the elastic gasket 141 and the sealing gasket 142 on the tightening nut 14, the tightness of the connection between the tightening nut 14 and the fixing hole 4 is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com