Rock three-axis fracturing device

A rock and axial pressure technology, applied in the field of rock triaxial fracturing devices, can solve the problems of low experimental efficiency, low degree of mechanization, and great manpower consumption, so as to improve the accuracy and efficiency of experiments, improve the degree of mechanization, and reduce artificial effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

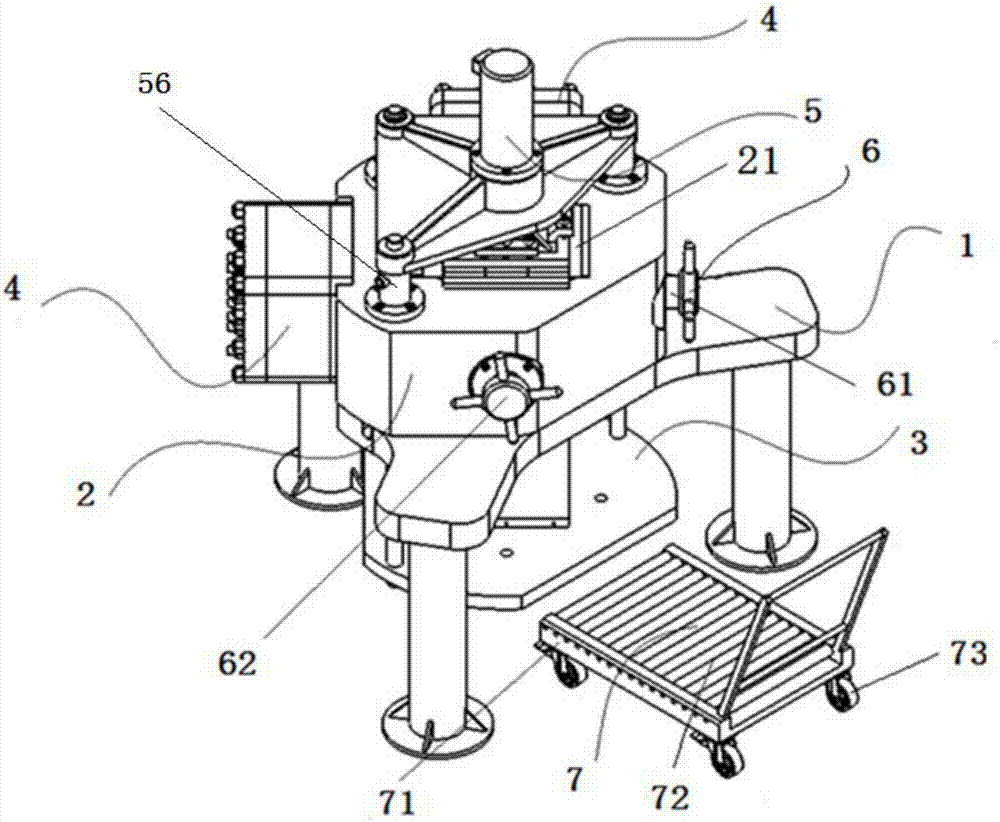

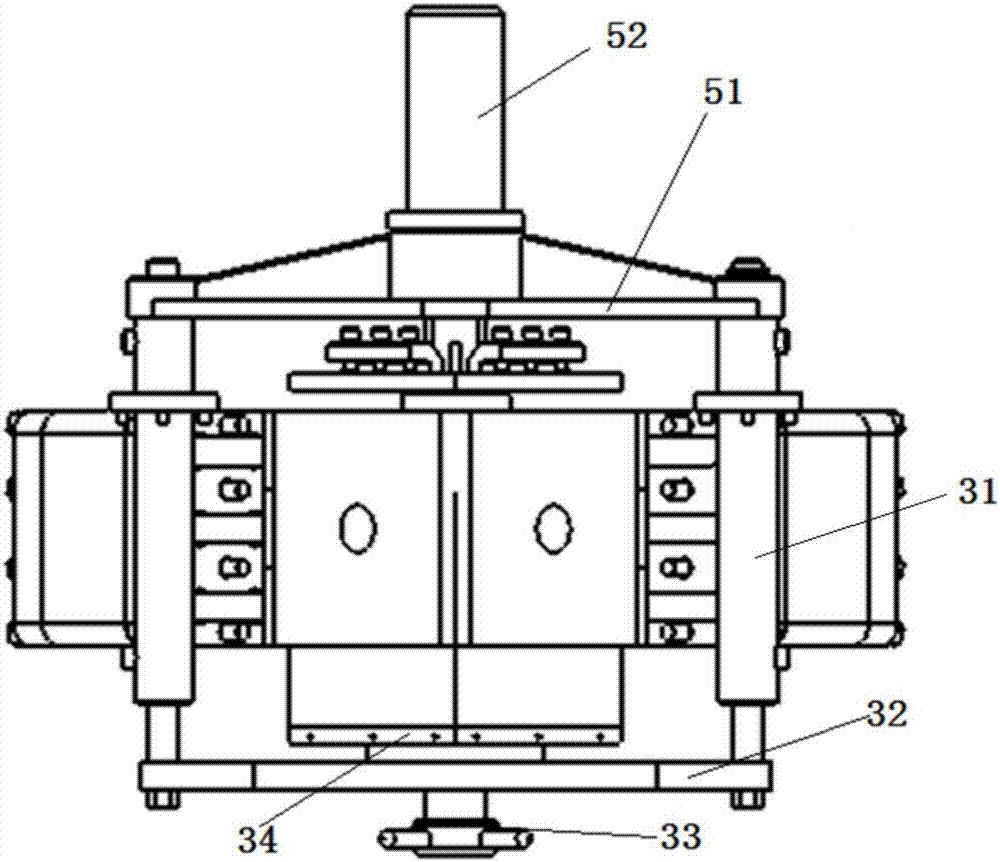

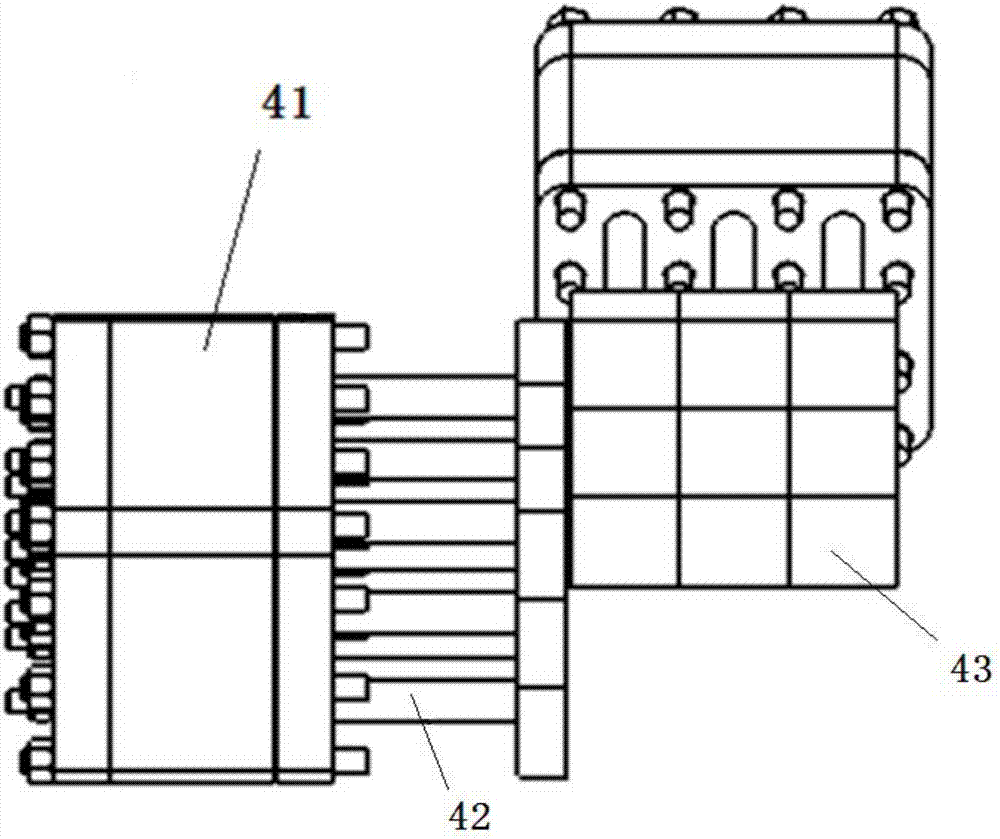

[0023] like Figure 1~5 As shown, the present invention provides a rock triaxial fracturing device, which includes a bracket 1, a main cavity 2, a pushing mechanism 3, a horizontal force applying mechanism 4 and a top force applying mechanism 5; the main cavity 2 is fastened to the On the support 1, the main cavity 2 has a through cavity 21 for accommodating the rock to be tested; the push mechanism 3 includes a hydraulic cylinder 31 and a supporting plate 32, and the cylinder bodies of the three hydraulic cylinders 31 vertically penetrate the main cavity 2, And they are respectively arranged in different directions around the through cavity 21, the supporting plate 32 is fixedly connected with the piston rod of each hydraulic cylinder 31; The force mechanism 4 includes a fixed block 41 and a hydraulic cylinder 42. The fixed block 41 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com