Mint cigarette paper having moisture retention function and preparation method thereof

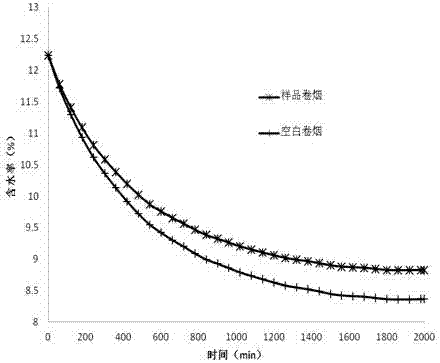

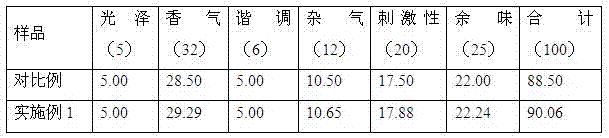

A technology of cigarette paper and mint, which is applied in the field of mint cigarette paper with moisturizing function and its preparation, can solve the problems of cigarette burning speed, ventilation degree, number of puffs, difficulty in controlling smoke, loss of aroma, difficulty in lasting, etc., and achieve Reduce the irritation of cigarettes, enhance the taste, and improve the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a menthol cigarette paper with moisturizing function, comprising the following steps:

[0023] (1) At room temperature, quickly add 10 mL of calcium chloride solution with a concentration of 0.5 mol / L to 100 mL of sodium polystyrene sulfonate solution with a concentration of 10 mg / mL, stir and mix evenly to obtain Aqueous solution of calcium and sodium polystyrene sulfonate; under stirring conditions, use a constant flow pump to add 10 mL of sodium carbonate solution with a concentration of 0.5 mol / L to the calcium chloride and polystyrene solution at a rate of 1 mL / min. The aqueous solution of sodium styrene sulfonate produces a white precipitate. After the sodium carbonate solution is added dropwise, stir for 1 hour, and then centrifuge in an ultracentrifuge (8000rpm, 3min) to obtain a precipitate. Separate the precipitate with deionized water and absolute ethanol Wash 3 times each, and dry at 60°C for 24 hours to obtain spherical calcium carbo...

Embodiment 2

[0035] A preparation method of a menthol cigarette paper with moisturizing function, comprising the following steps:

[0036](1) At room temperature, quickly add 10 mL of calcium chloride solution with a concentration of 0.5 mol / L to 100 mL of sodium polystyrene sulfonate solution with a concentration of 10 mg / mL, stir and mix evenly to obtain Aqueous solution of calcium and sodium polystyrene sulfonate; under stirring conditions, use a constant flow pump to add 10 mL of sodium carbonate solution with a concentration of 0.5 mol / L to the calcium chloride and polystyrene solution at a rate of 1 mL / min. The aqueous solution of sodium styrene sulfonate produces a white precipitate. After the sodium carbonate solution is added dropwise, stir for 0.5 hours, and then centrifuge in an ultracentrifuge (8000rpm, 3min) to obtain a precipitate. Separate the precipitate with deionized water and absolute ethanol Wash 3 times each, and dry at 60°C for 24 hours to obtain spherical calcium car...

Embodiment 3

[0041] A preparation method of a menthol cigarette paper with moisturizing function, comprising the following steps:

[0042] (1) At room temperature, quickly add 10 mL of calcium chloride solution with a concentration of 0.5 mol / L to 100 mL of sodium polystyrene sulfonate solution with a concentration of 10 mg / mL, stir and mix evenly to obtain Aqueous solution of calcium and sodium polystyrene sulfonate; under stirring conditions, use a constant flow pump to add 10 mL of sodium carbonate solution with a concentration of 0.5 mol / L to the calcium chloride and polystyrene solution at a rate of 1 mL / min. The aqueous solution of sodium styrene sulfonate produces a white precipitate. After the sodium carbonate solution is added dropwise, stir for 1.5 hours, and then centrifuge in an ultracentrifuge (8000rpm, 3min) to obtain a precipitate. Separate the precipitate with deionized water and absolute ethanol Wash 3 times each, and dry at 60°C for 24 hours to obtain spherical calcium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com