High-precision automatic processing technology with stone texture recognition function

An automatic processing, high-precision technology, applied in decorative arts, decorative structures, etc., can solve problems affecting processing performance and effect, uneven texture distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

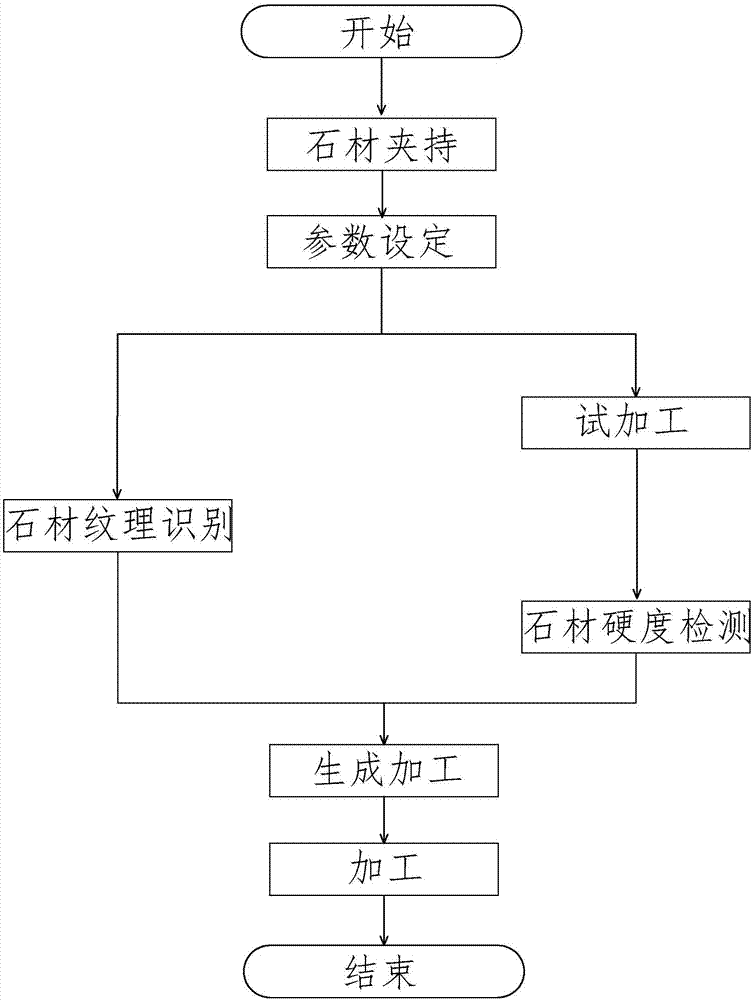

[0022] Such as figure 1 As shown, a high-precision automatic processing technology with stone hardness detection function, including:

[0023] The preparatory processing process can be divided into two steps: stone clamping and parameter setting; specifically, the stone is clamped by the fixture on the robot. The current stone processing methods are suitable for commonly used stone materials such as granite, marble, limestone, sandstone, and slate. Relatively uniform processing parameters and corresponding tools, the processing parameters may include the rotation speed of the tool, processing time, etc. After determining the type of stone to be processed, then determine the processing tool and processing parameters corresponding to the type of stone. The cutting tool is preferably a drill, and the processing parameters can be the speed and cutting time of the drill, and the corresponding drill drills the stone under the setting of the fixed speed and cutting time, and is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com