Structural surface crack detection method based on fusion of image features and Bayesian data

A data fusion and image feature technology, applied in image data processing, image enhancement, image analysis, etc., can solve the problems of inconspicuous contrast between cracks and surrounding areas, high false alarm rate and false alarm rate, and small cracks in structural components. Achieve the effect of reducing labor costs, improving detection rates, and reducing burdensomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

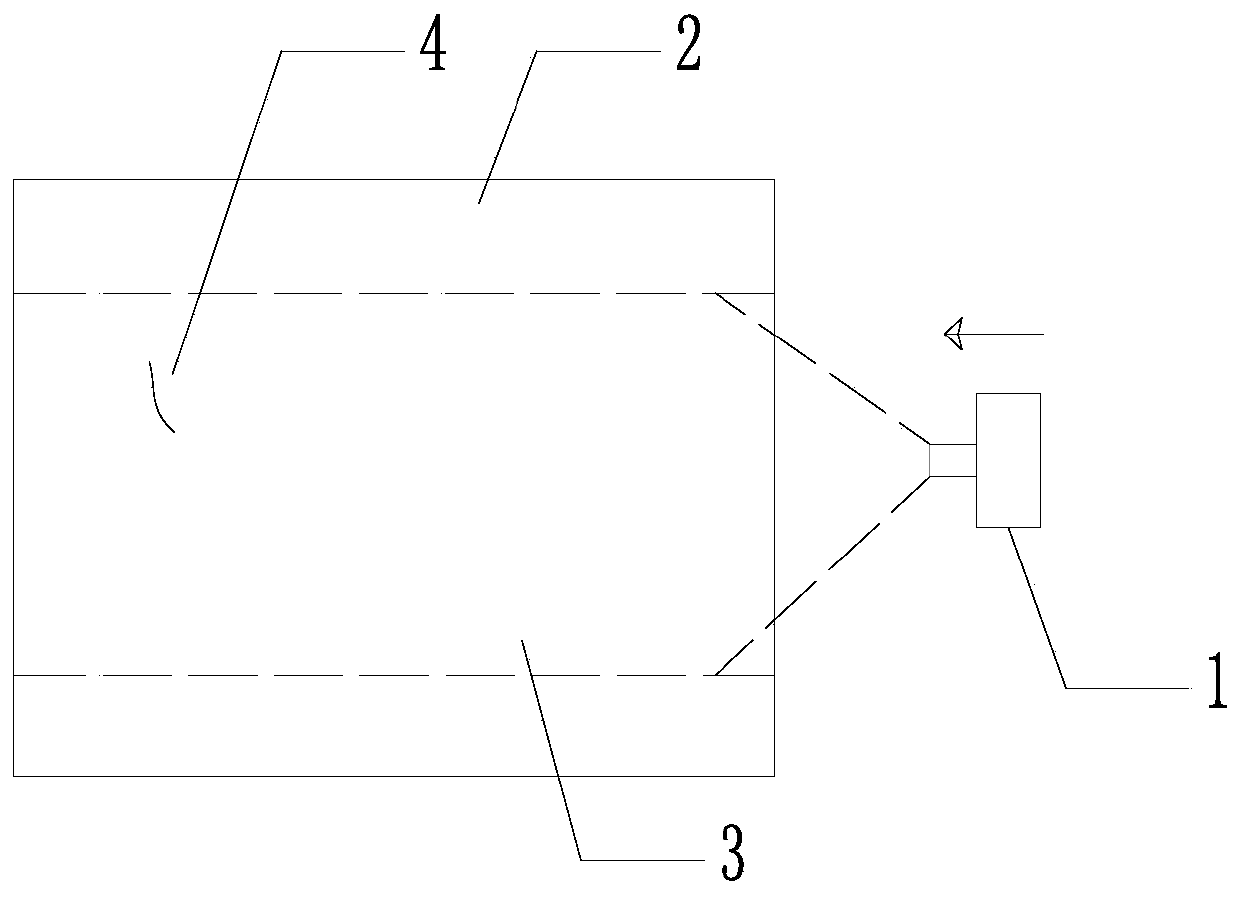

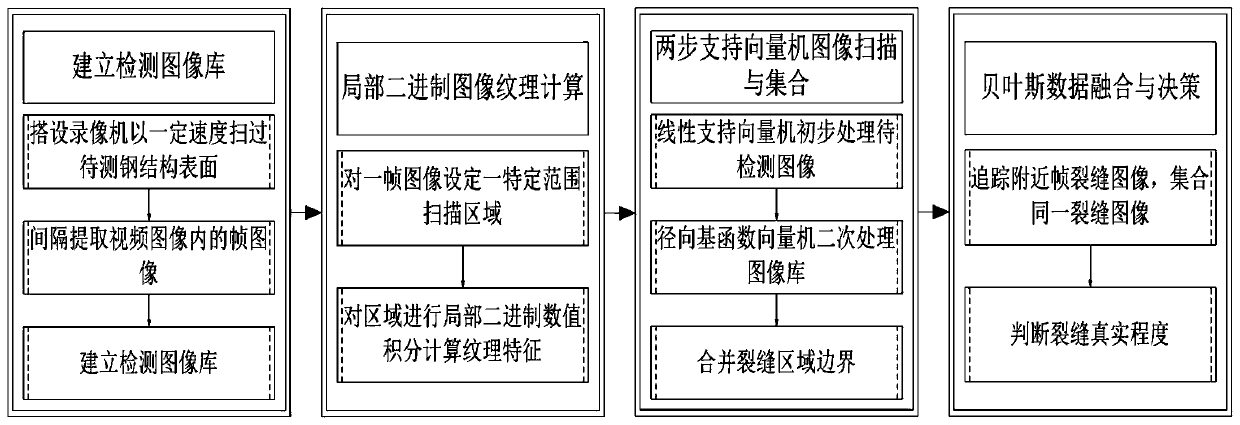

[0031] The following combination figure 1 The target video acquisition schematic shown in and figure 2 The implementation flow chart shown in further illustrates the specific embodiment of the present invention.

[0032] figure 1 The codes in represent respectively:

[0033] 1 - video recorder;

[0034] 2 - the structural surface of the target structural member;

[0035] 3——Video field of view of the video recorder;

[0036] 4——Cracks on the surface of the target structure;

[0037] Remarks: When the present invention collects the video of the surface of the structural member, conditions that cause the surface to produce strong light should be avoided.

[0038] The structural surface crack detection method based on the fusion of image features and Bayesian data, the specific steps are as follows:

[0039] A. Collect surface video images of structural components and establish a detection image library;

[0040] A1. Select the target structural member (2), and use the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com