Portable high-power load modules easy to assemble

A high-power load and load module technology, which is applied in the direction of measuring devices, instruments, and measuring electronics, can solve the problem of not being able to take into account the test power and volume, and achieve the effect of being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

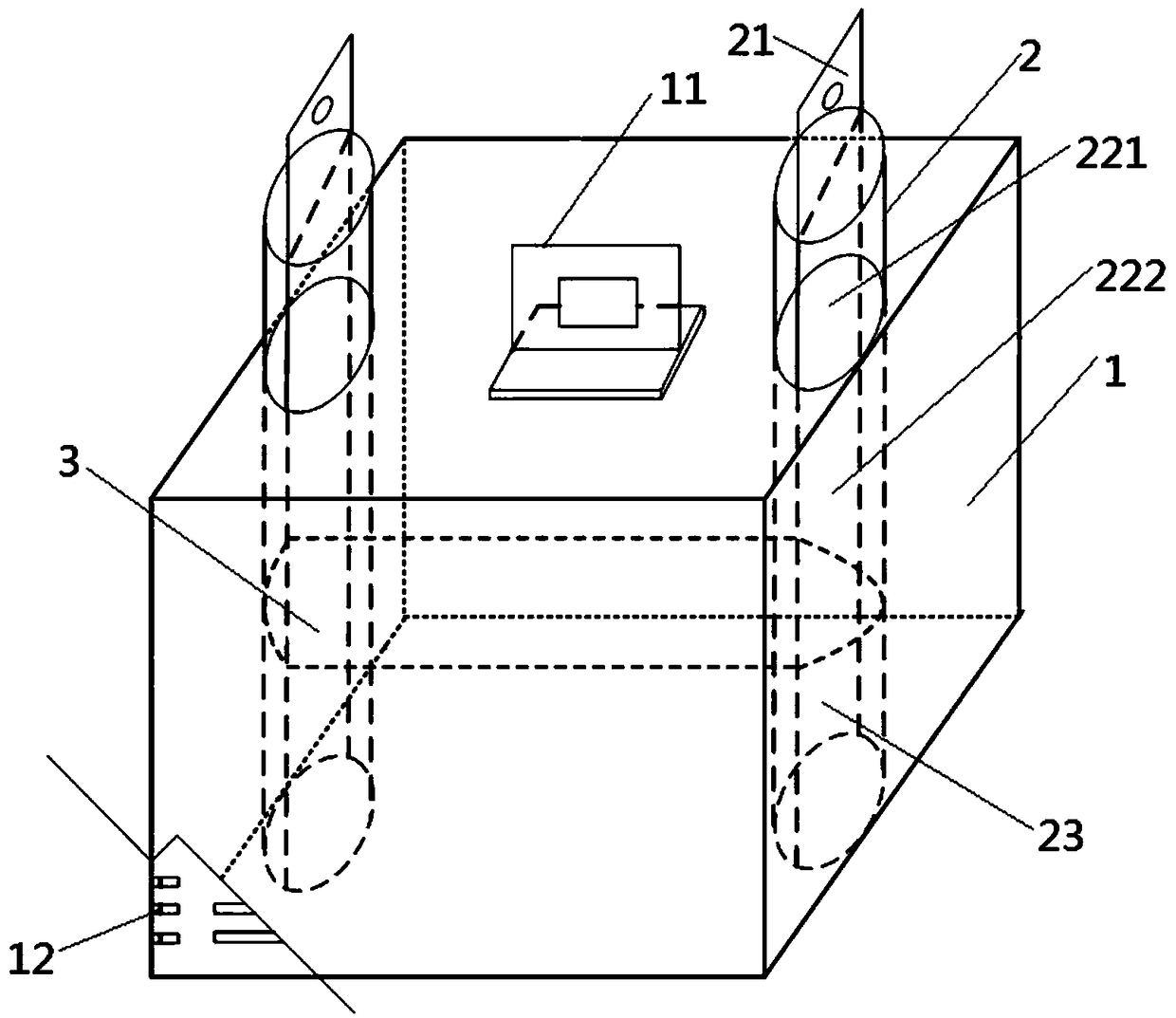

[0028] refer to figure 1 , a portable easy-to-assemble high-power load module, the load module is used to form charging pile test equipment, the load module includes an integrated box 1, two terminal posts 2 and a resistance module 3;

[0029] In this application, the charging pile testing equipment body is combined with the expanded load module to form the charging pile testing equipment, so as to meet the requirements of the charging pile testing power. The load module adopts miniaturization, light weight, box-type design, integrates components such as high-power resistance module 3 and terminal post 2, and has a reasonable structure. This module has outstanding advantages such as large load current, flexible power adjustment, portability, and wide application. It can meet the diversified detection and test requirements of various charging facilities.

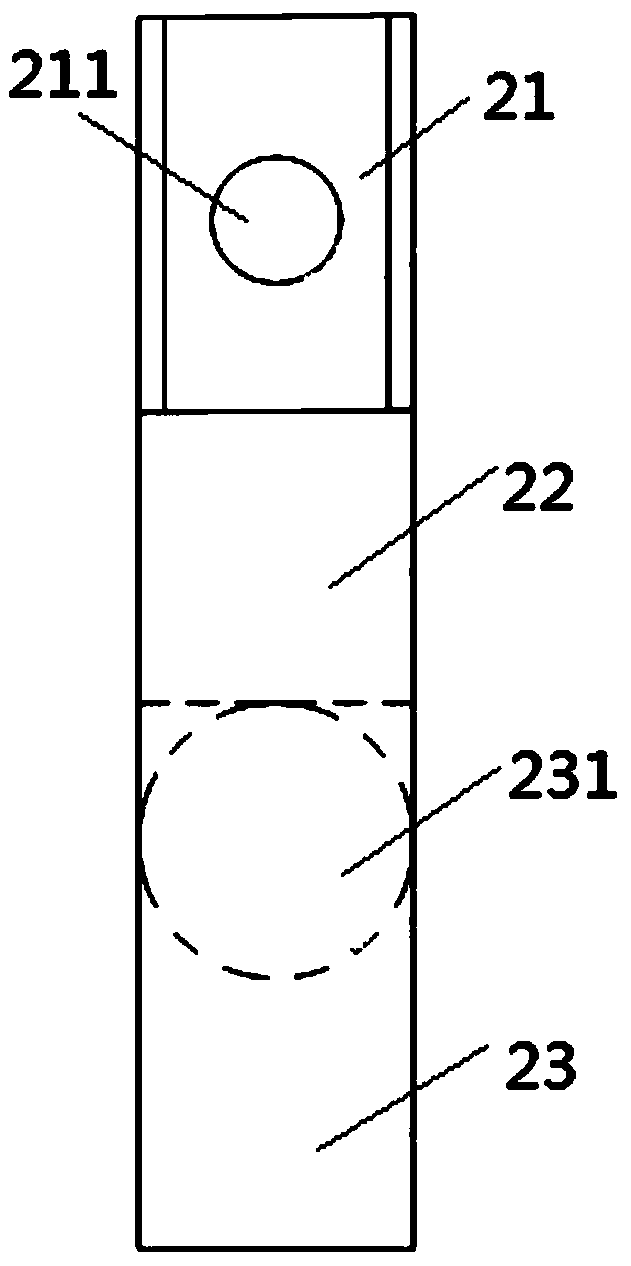

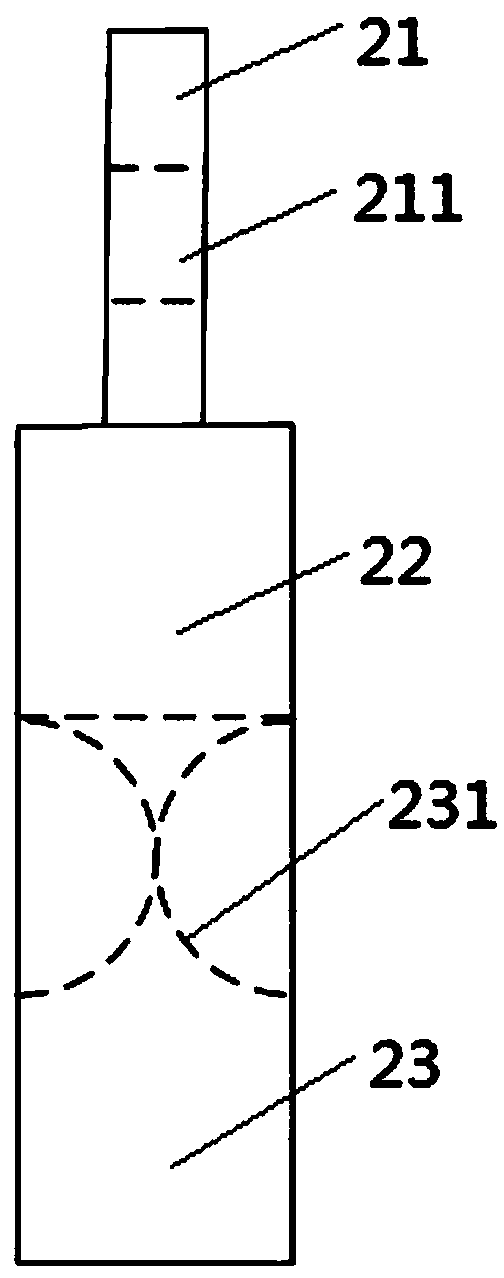

[0030] refer to Figure 2(a) , 2(b) and 2(c), the terminal 2 includes a power line interface board 21, a solid cylinder ...

Embodiment 2

[0040] Embodiment two, the difference with embodiment one is only:

[0041] Further, a handle 11 is provided on the upper end surface of the integrated box body 1 . Since charging piles are distributed in different locations, portability is a very important factor for charging pile test equipment. The integrated box body 1 described in the embodiment of the present application is provided with a handle 11, which is reasonable in structure and convenient for technicians to carry, and enables technicians to carry out testing and testing of charging facilities in different environments and places.

[0042] Further, the front panel, the rear side panel, the left side panel, the right side panel and the bottom panel of the integrated box 1 are all provided with cooling holes 12 . The cooling holes 12 can dissipate heat naturally when working at the rated power or below, so as to prevent the load module from running at an overheated temperature and premature aging.

[0043] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com