Car lock locking mechanism

A car, the other side of the technology, applied in the field of car locks and locking mechanisms, can solve the problems of poor user comfort, loud noise, and poor sense of the user, achieving small space ratio, fewer parts, and improved use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

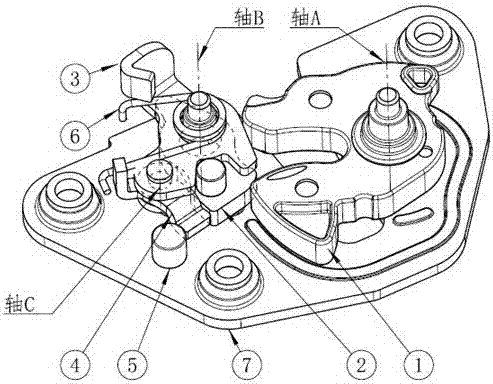

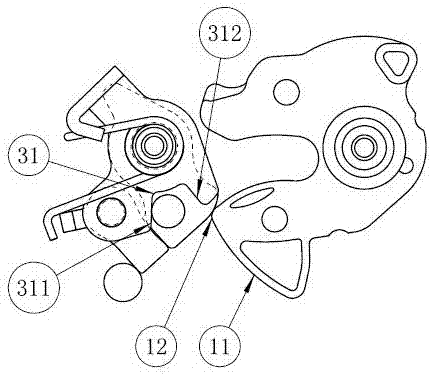

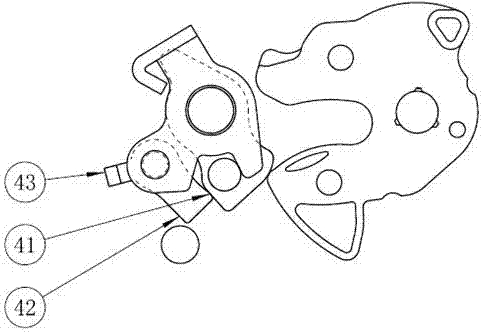

[0024] A locking mechanism for an automobile, comprising a bottom plate 7 with a lock opening, and a first rotating shaft A, a second rotating shaft B, a third rotating shaft C and a blocking block 5 arranged at a predetermined position of the bottom plate 7; wherein the first rotating shaft A rotary clamp 1 is installed on a rotating shaft A through a clamp torsion spring, an opening arm 3 and a stop pawl 2 are installed on the second rotating shaft B at the same time, a blocking arm 4 is installed on the third rotating shaft C and the blocking arm 4 Located between the stop pawl 2 and the blocking block 5 , one end of the torsion spring 6 of the stop pawl is fixed to abut against the protruding portion 43 of the blocking arm 4 .

[0025] In the above arrangement of this embodiment, the rivet is used as the rotating shaft to be riveted on the bottom plate 7, and other methods can also be used, which are not listed one by one. The characteristic is that the riveting shaft and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com