Air-curing frame

A technology for drying racks and limiting holes, which is applied in the field of drying racks, and can solve the problems of large occupied space, single structure of drying racks, inability to use long pole drying racks, etc., and achieve the effect of easy use and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

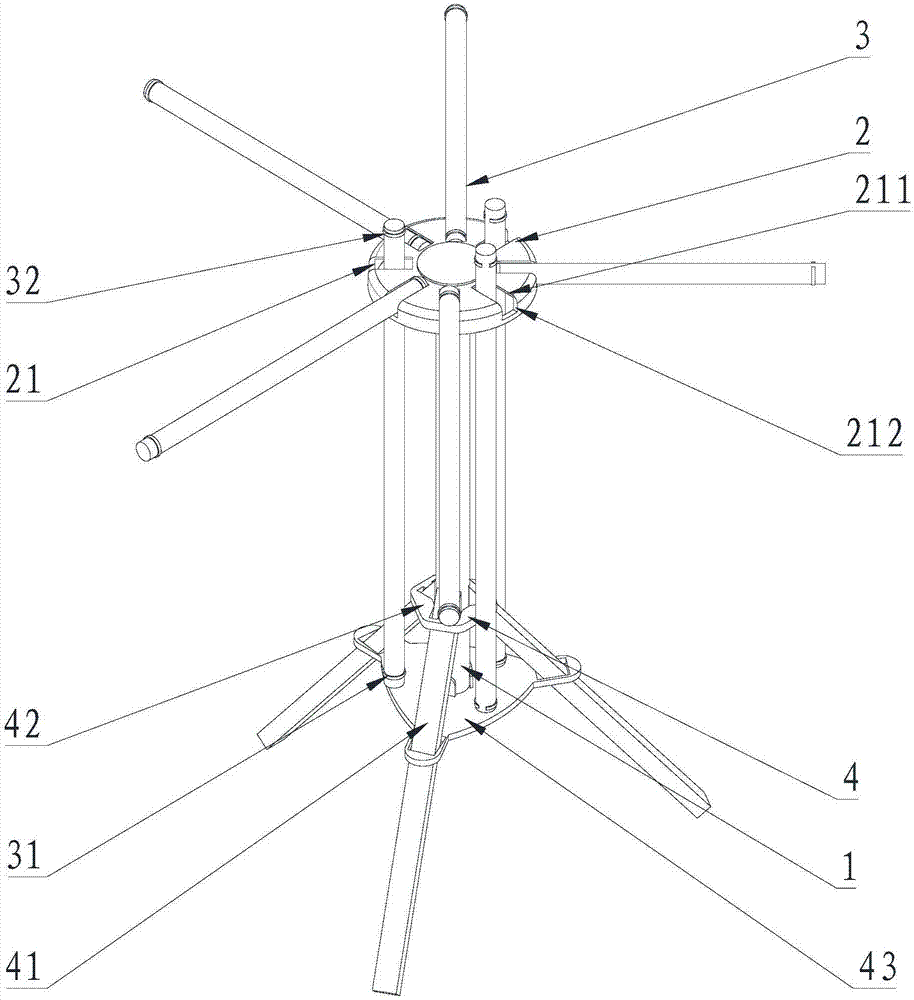

[0033] Please refer to figure 1 , Embodiment 1 of the present invention is: a drying rack, comprising a storage tray 2 with a limiting hole 21 arranged at one end of the main shaft 1 and a first limiting hole 21 passing through the limiting hole 21 and both ends are respectively sleeved. The supporting rod 3 of the position ring 31 and the second limit ring 32;

[0034] The width of the limiting hole 21 is smaller than the outer diameters of the first limiting ring 31 and the second limiting ring 32 .

Embodiment 2

[0035] Please refer to figure 1 , the second embodiment of the present invention is: a drying rack, including a storage tray 2 with a limiting hole 21 arranged at one end of the main shaft 1 and a first limiting hole 21 passing through the limiting hole 21 and two ends are respectively sleeved. The supporting rod 3 of the position ring 31 and the second limit ring 32;

[0036] The widths of the limiting holes 21 are respectively smaller than the outer diameters of the first limiting ring 31 and the second limiting ring 32 .

[0037] The middle part of the storage tray 2 is hinged to the one end of the main shaft 1 . The limiting holes 21 are arranged on the storage tray 2 in a circular array. The length of the limiting hole 21 is less than the axial distance from the first limiting ring 31 to an end of the support rod 3 close to the first limiting ring 31 . The shape of the storage tray 2 is a cylinder with a hole at the bottom, and the limit hole 21 includes a first limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com