A semi-active exhaust muffler

An exhaust muffler, semi-active technology, applied in mufflers, engine components, machines/engines, etc., can solve the problems of complex structure and short service life of mufflers, and achieve the purpose of reducing maintenance frequency, avoiding low-frequency resonance and reducing impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As mentioned in the background art section, the current exhaust muffler is not only bulky, but also weak in impact resistance and short in service life.

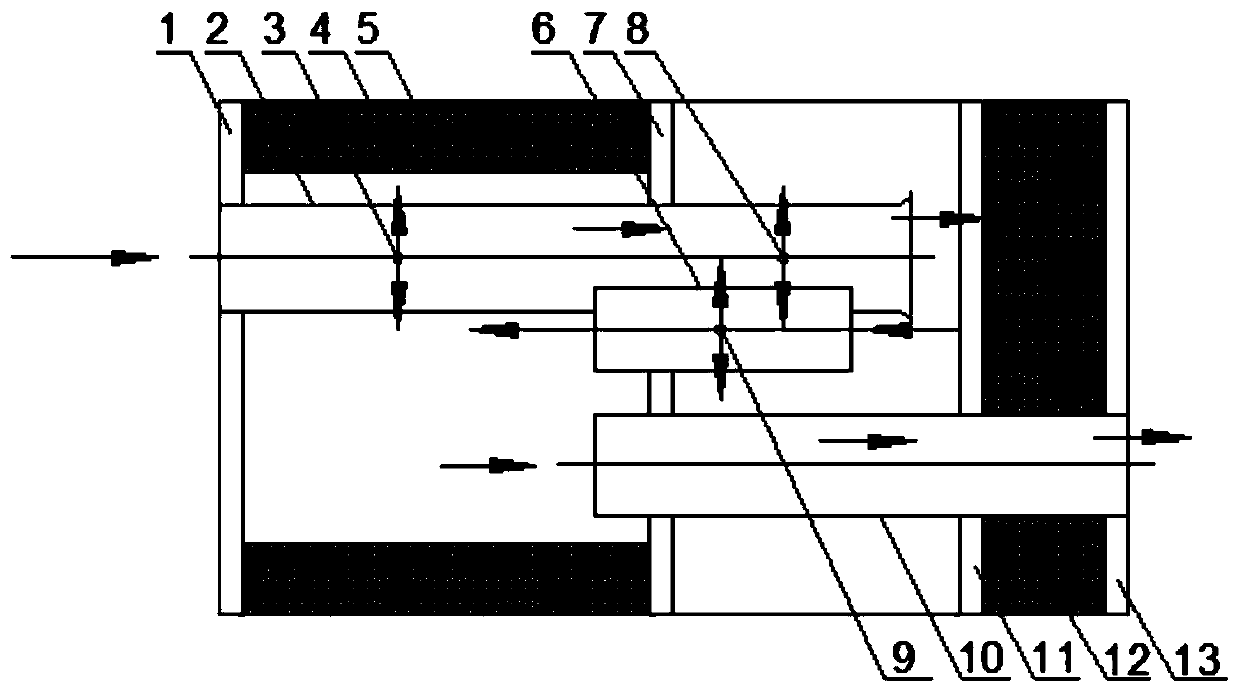

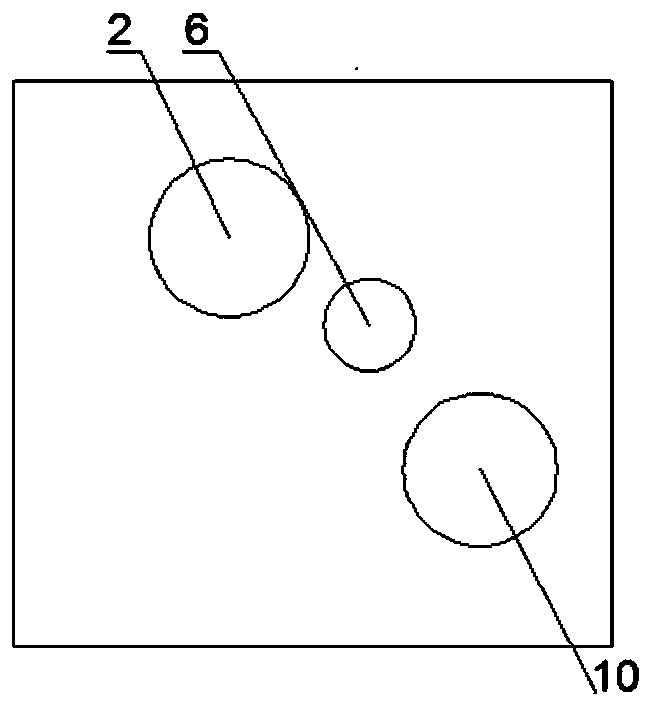

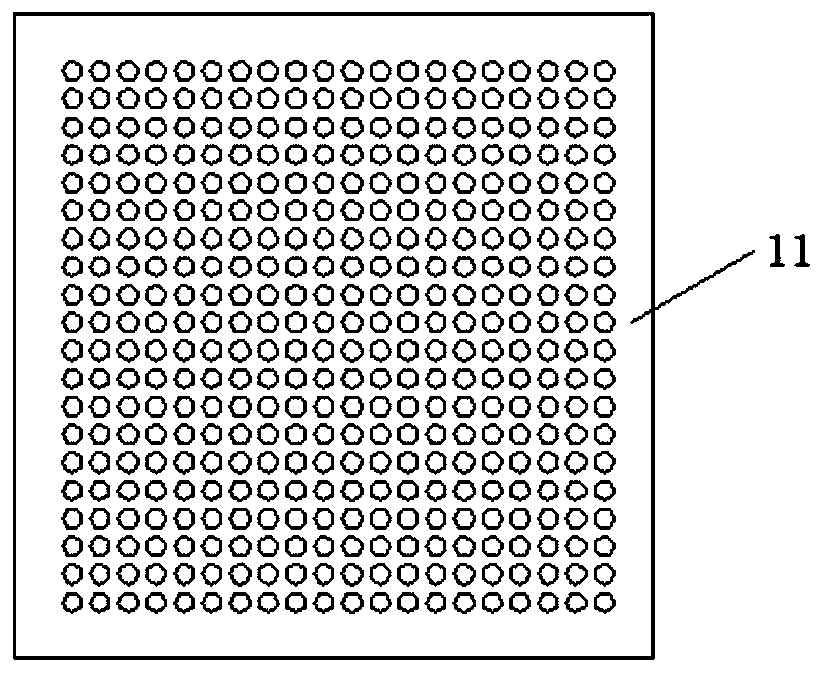

[0026] Based on the above research, the embodiment of the present invention provides a semi-active exhaust muffler. Compared with the traditional Helmholtz muffler, the muffler with this structure can effectively reduce the complexity of its structure. In addition, when noise enters the sound-absorbing component, it will have a force effect on the triangular-like unit cell in the sound-absorbing component, and the force effect will cause a small deformation of the triangular-like unit cell to adapt to the noise and achieve the premise of sound absorption In this way, the impact on the sound-absorbing components is reduced, thereby reducing the maintenance frequency of the muffler and increasing the service life.

[0027] In order to make the above objects, features and advantages of the present invention more comprehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com