A partial discharge ultrasonic localization method based on flexible array sensors

A flexible array and ultrasonic positioning technology, applied in the detection field, can solve the problems that the array sensor cannot be detected and the array elements cannot be attached, and achieve the effect of solving the problem of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The purpose of the present invention is to provide a positioning method based on a flexible array sensor for the shortage of the application range of the existing ultrasonic array sensor, so as to realize the precise positioning of the partial discharge source of any electrical equipment.

[0044] Problem described in the present invention is realized with following technical scheme:

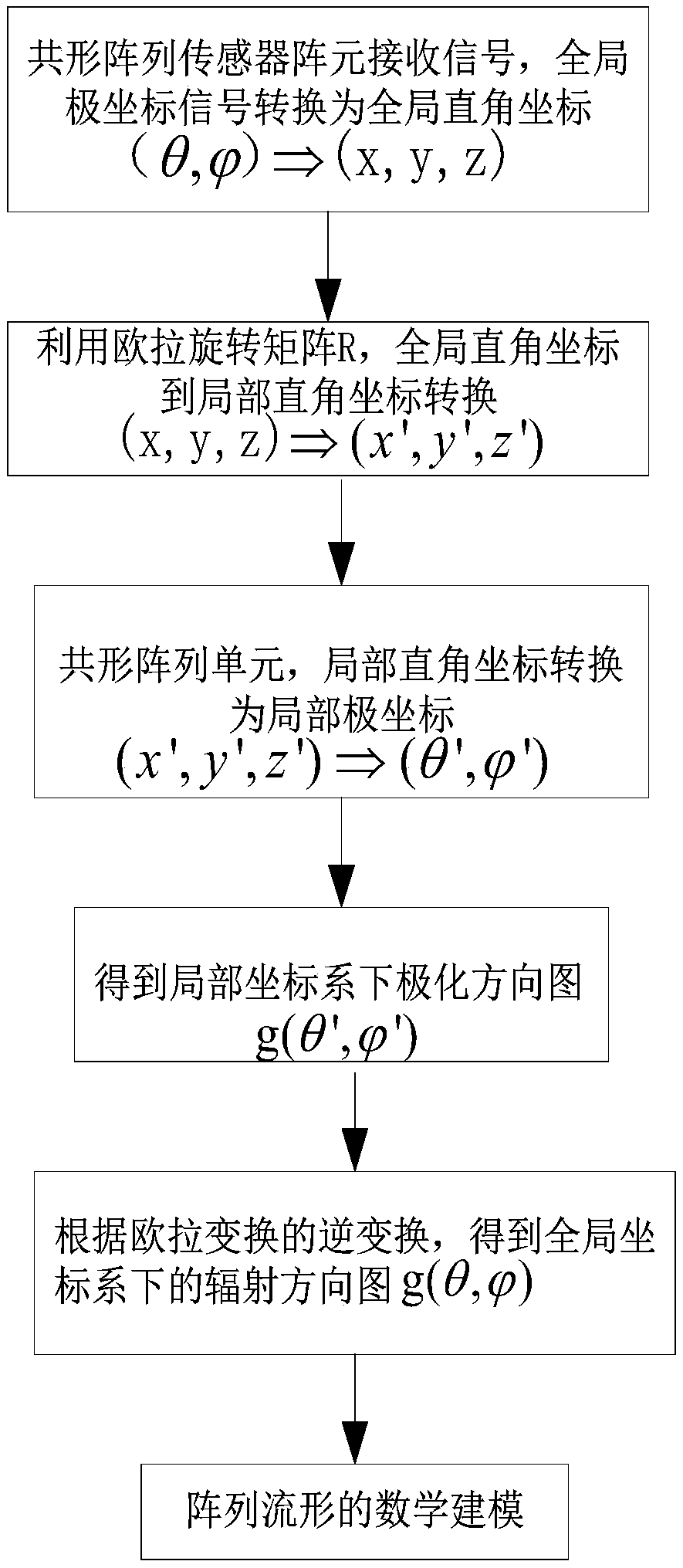

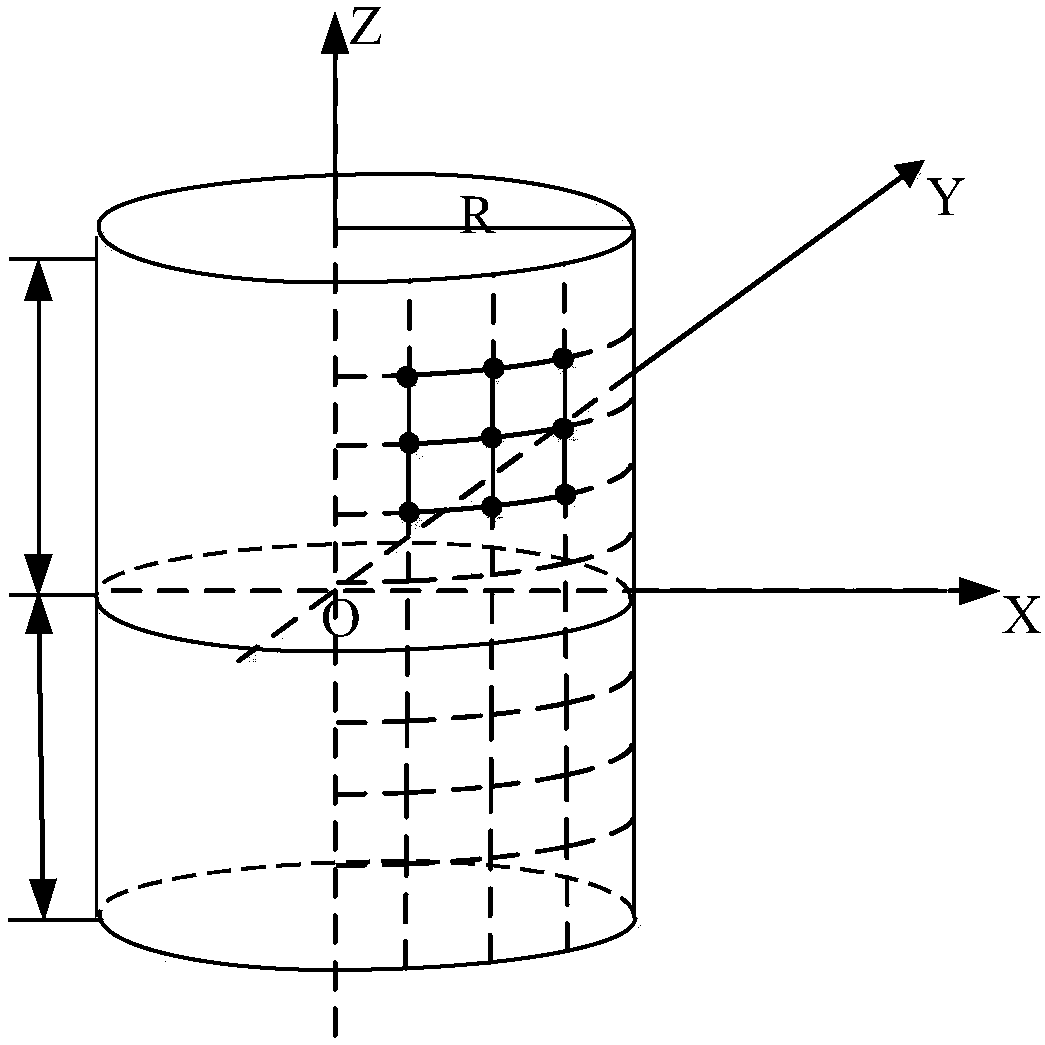

[0045] Principle and implementation steps:

[0046] ①Design of flexible array sensor

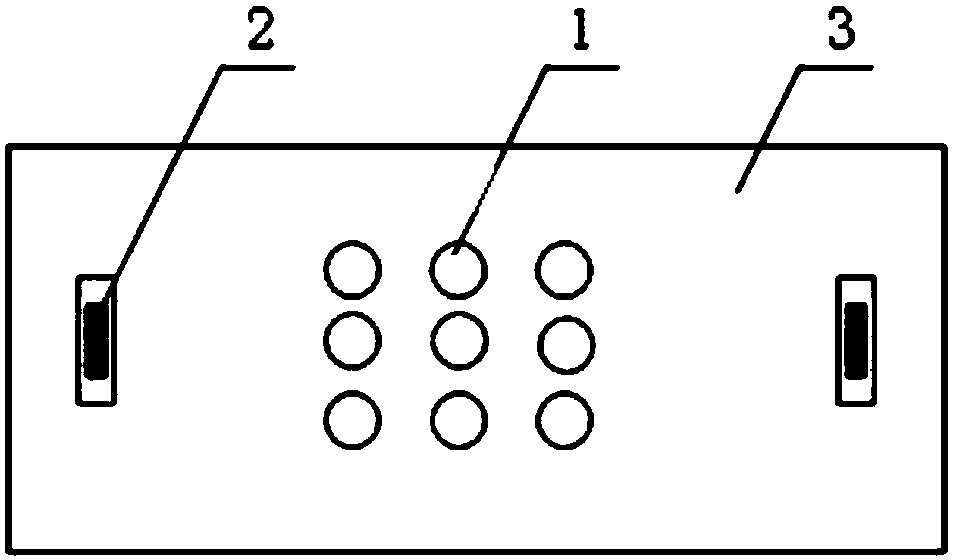

[0047] The flexible partial discharge ultrasonic array sensor of the present invention includes a flexible base 3 and a magnet 2 with array holes not less than 3×3. The flexible base 3 is provided with nine array element installation holes arranged in a square, and the ultrasonic sensor array element 1 is placed in the holes. The front and rear ends of the flexible base 3 are provided with magnets 2 and fixed plates, and the fixed plate is provided with suction cups, so that the sensor array element c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com