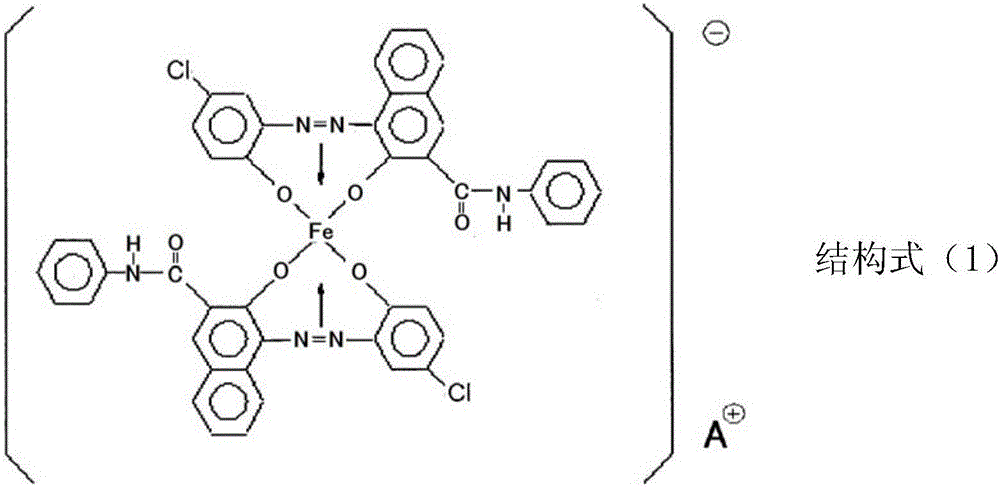

Toner, toner collecting unit, image forming device and image forming method

A toner image and toner technology, applied in the field of toner, can solve the problems of stress resistance (deterioration of durability, decrease of resin chargeability, deterioration of background staining, etc.), and achieve excellent conjunctiva resistance, conjunctiva resistance low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0214]

[0215]

[0216]After the mixture of the above composition is fully stirred and mixed with a Henschel mixer, it is heated and melted at a temperature of 130 to 140° C. with a roller mill for about 30 minutes. mesh size of 1.5 mm), and then pulverized and classified by a jet mill, a mechanical pulverizer, or a wind classifier to obtain a toner matrix with a volume average particle diameter of 6.8 μm. 0.5% by mass of hydrophobic silica was added to the obtained toner matrix and mixed to obtain a final toner.

Embodiment 2

[0218] In Example 1, the polyester resin A was changed to polyester resin B, the polyester resin G was changed to polyester resin H, and the metal (iron) azo compound (T-77) was changed to 3 parts, except that In the same manner as in Example 1, a toner was obtained.

Embodiment 3

[0220] A toner was obtained in the same manner as in Example 1 except that polyester resin A was changed to polyester resin C, and polyester resin G was changed to polyester resin I in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com