Device for aligning and righting preforms, comprising bowl centrifuge equipped with damper

A technology of preforms and shock absorbers, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increased travel time of preforms, unsatisfactory, large size of centrifugal drum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

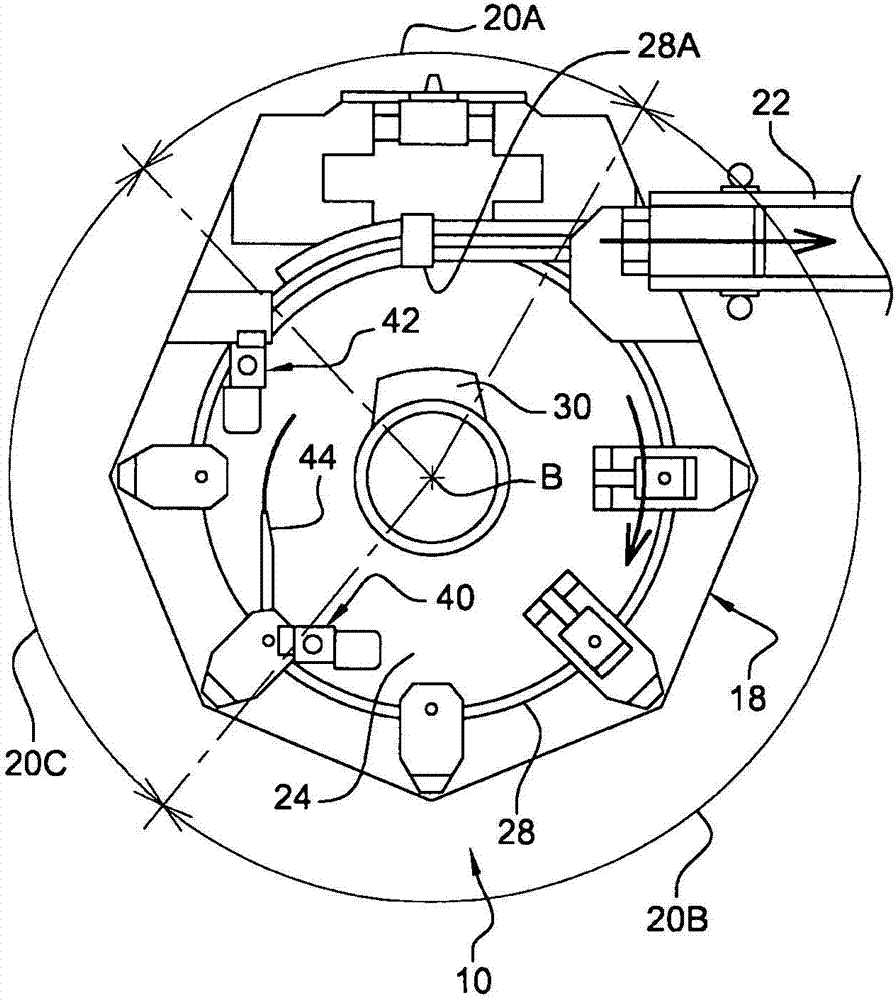

[0050] In the following description, components having the same structure or similar functions will be denoted by the same reference numerals.

[0051] In the following description, without limitation, the following local orientations are taken for each preform present in the centrifuge bowl of the apparatus:

[0052] - a radial direction R, which is oriented from the inside to the outside from the axis of rotation of the turntable;

[0053] - a tangential direction T, which is orthogonal to the radial direction R, extending in the plane of the turntable, oriented from upstream to downstream in the direction of rotation of the turntable;

[0054] - Vertical direction V, which is oriented from bottom to top in the direction opposite to gravity.

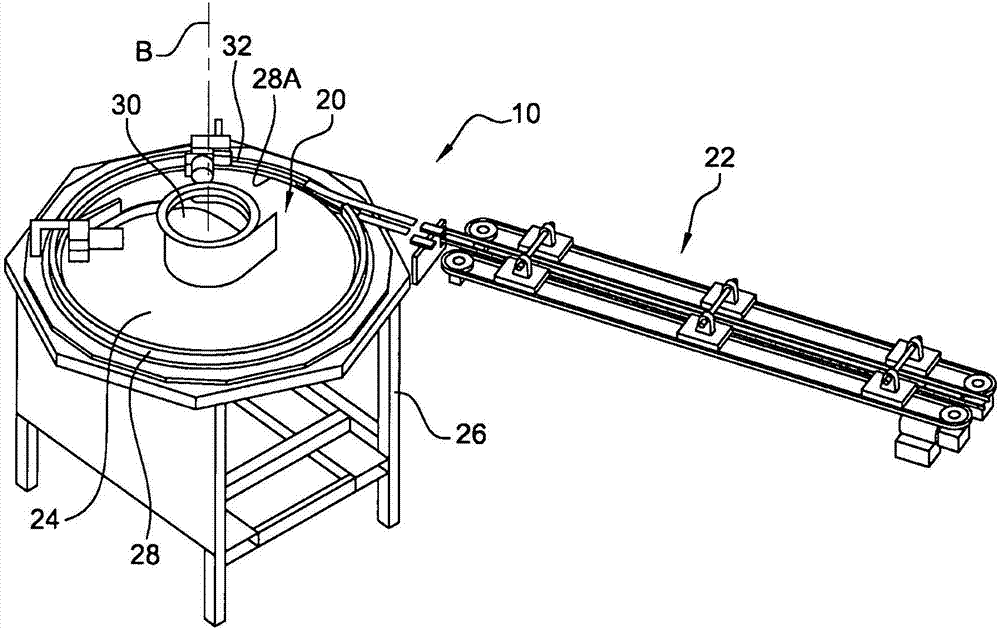

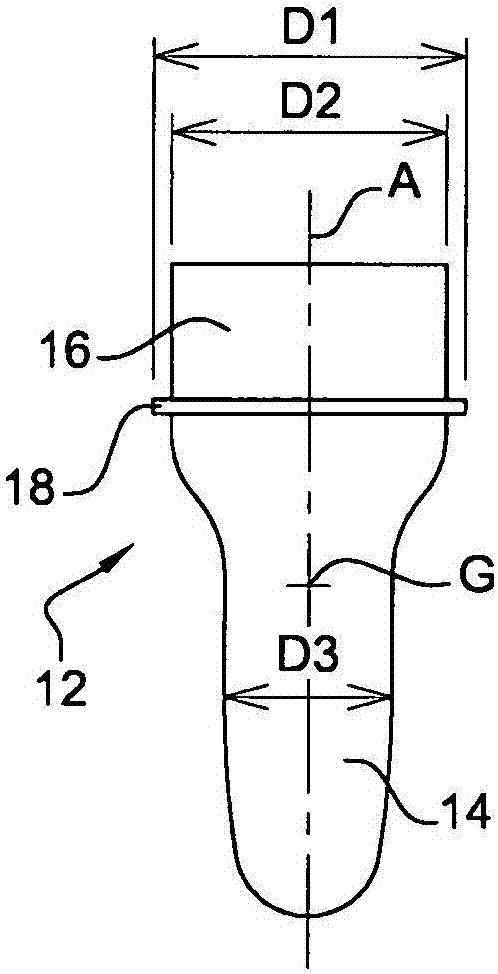

[0055] figure 1 shows a device 10 for arranging and erecting preforms 12 for forming containers of thermoplastic material by molding of preforms, in particular blow molding or stretch blow molding components of the device (not shown)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com