Vehicle pneumatic tire with tread

A technology for pneumatic tires and treads, which is applied to the field of vehicle pneumatic tires with treads, can solve problems such as unfavorable dry operation performance, and achieve the effects of improving dry braking, simple production process and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

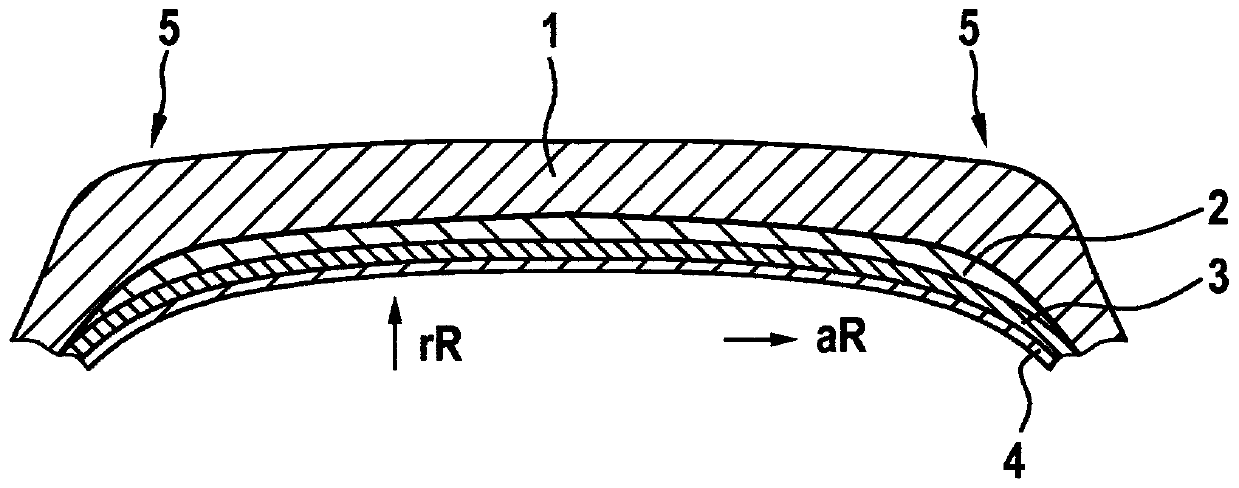

[0030] figure 1 A partial section of a car tire is shown schematically and by way of example. The usual constituents of this tire include in particular: a tread 1, a belt structure 2 arranged radially inside the tread 1 and comprising a plurality of cord belt layers, and optionally a belt band, furthermore a radial carcass 3. The largely airtight inner liner 4, and the sidewalls (not shown), as well as the bead areas (with bead cores, core profiles, and possibly also reinforcing plies arranged in these bead areas ). The tread 1 is equipped, inter alia, with profiles (not shown) in a manner known per se.

[0031] The tread 1 extends across the width of the tire in the ground contact zone and ends in the shoulder zone 5 . In these shoulders, it is possible to provide a tread termination zone composed of sidewall compound.

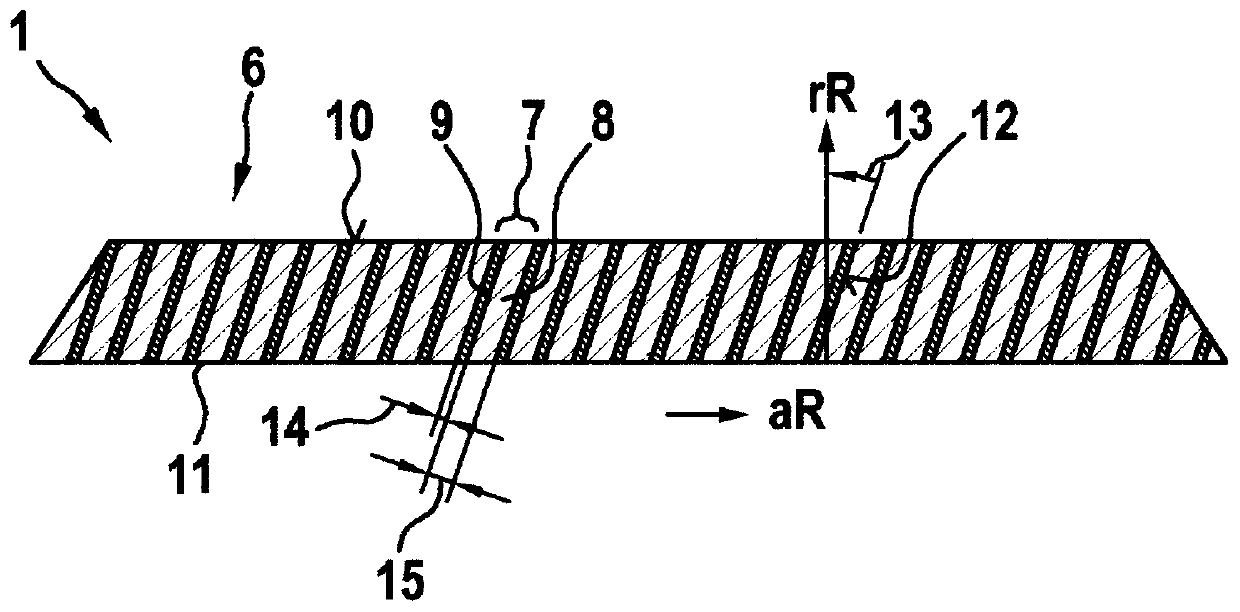

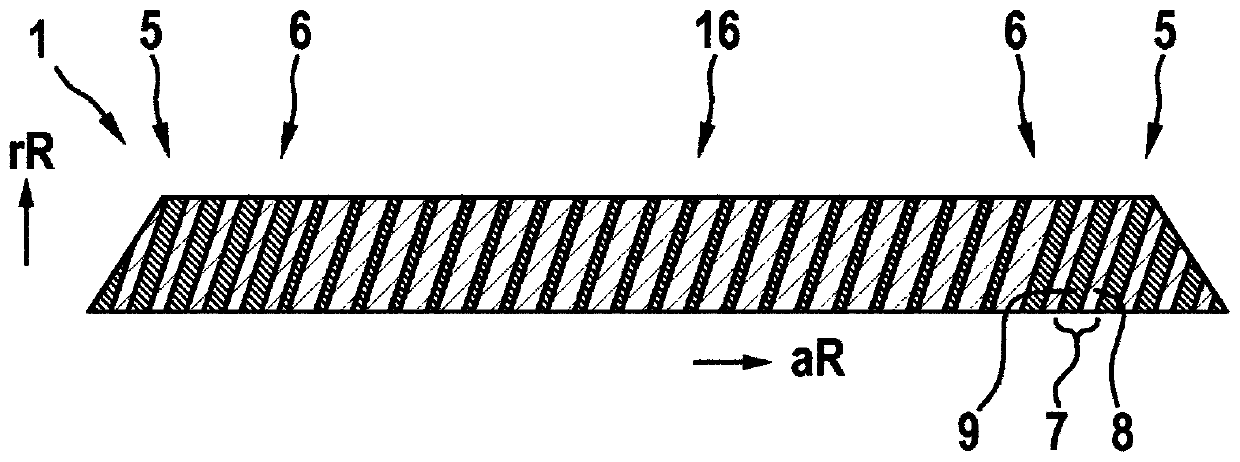

[0032] Figure 2 to Figure 6 Each schematically shows an embodiment of the tread according to the invention. These examples are suitable for figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com