High-controllability asymmetric pattern tire

A controllable and asymmetric technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problem of ignoring one and the other, improve drainage, improve drainage performance, and ensure straight-line driving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

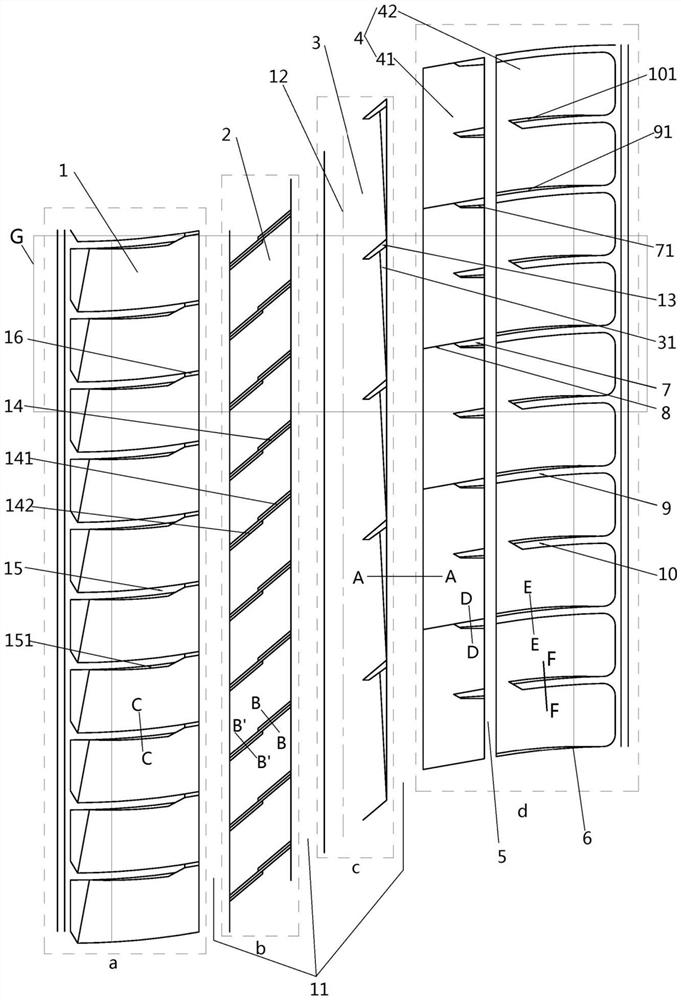

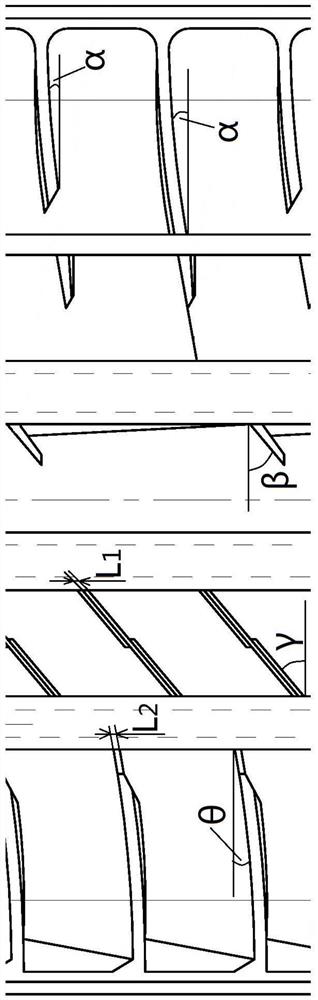

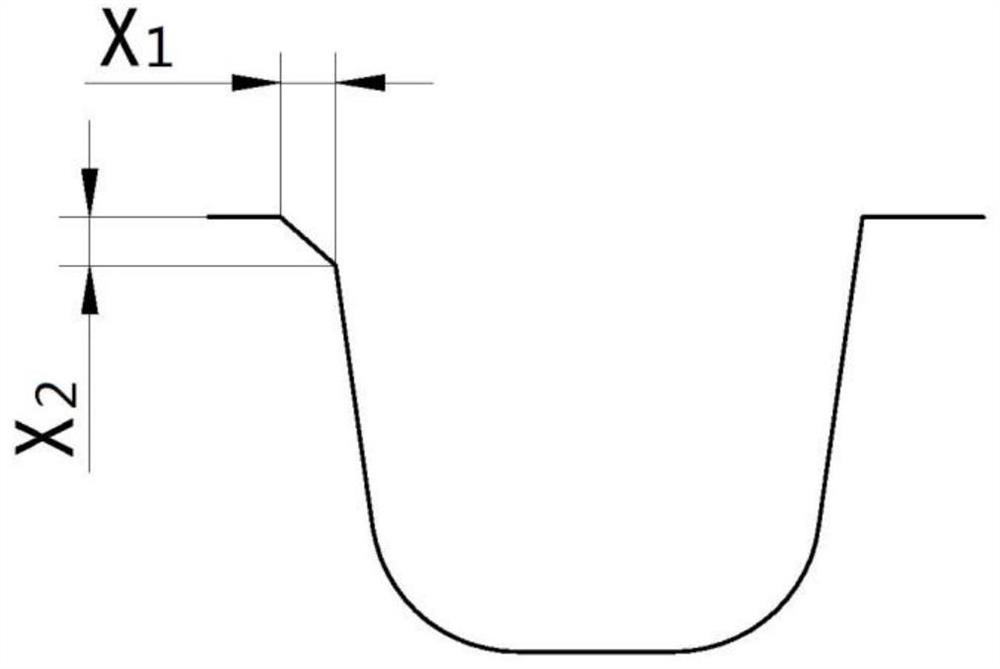

[0032] A high-handling asymmetric tread tire comprising a tread such as figure 1 As shown, the tread is provided with an inner shoulder block 1, a crown block 2, a middle block 3 and an outer shoulder block 4 in sequence; the width of the outer shoulder block 4 is larger than that of the inner shoulder. The outer block 1, the crown block 2 and the middle block 3, the outer shoulder block 4 is provided with a longitudinal auxiliary groove 5 on the inner side, and the left side of the longitudinal auxiliary groove 5 is the first outer shoulder The pattern block 41 and the right side are the second outer shoulder pattern block 42; the first outer shoulder pattern block 41 is provided with several first transverse grooves 7 on the side close to the tire shoulder 6, and the first tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com