Pneumatic tire

A technology for pneumatic tires and tires, which is applied to heavy-duty tires, tire parts, tire treads/tread patterns, etc., can solve problems such as the influence of transition characteristics, and achieve improved transition characteristics, good handling stability, and improved handling stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

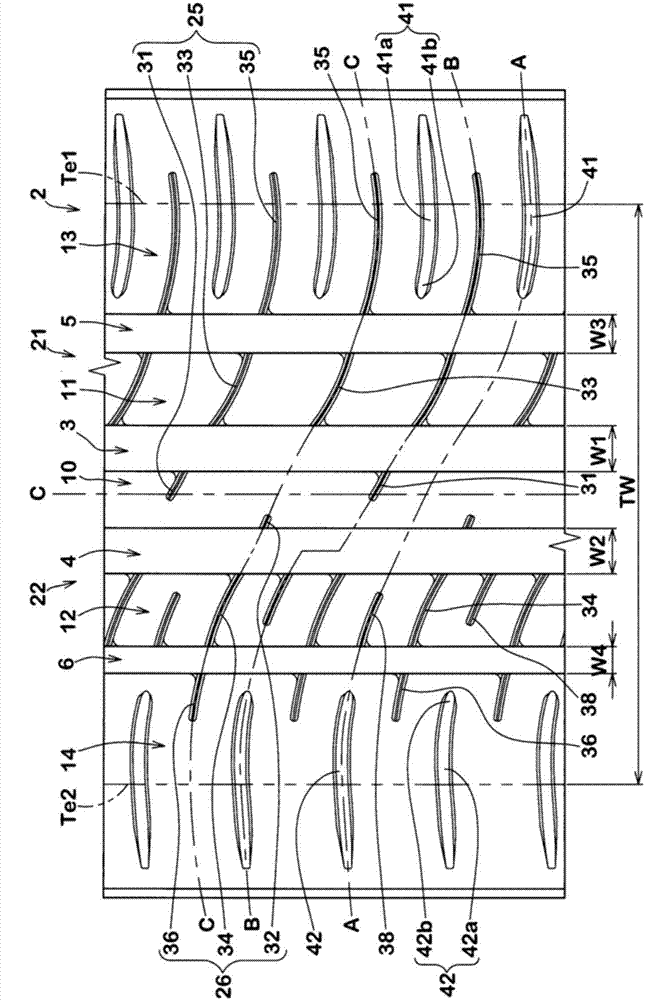

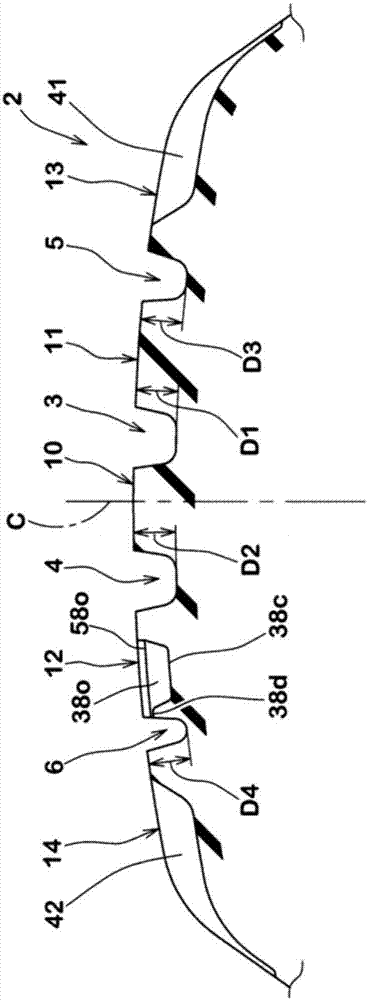

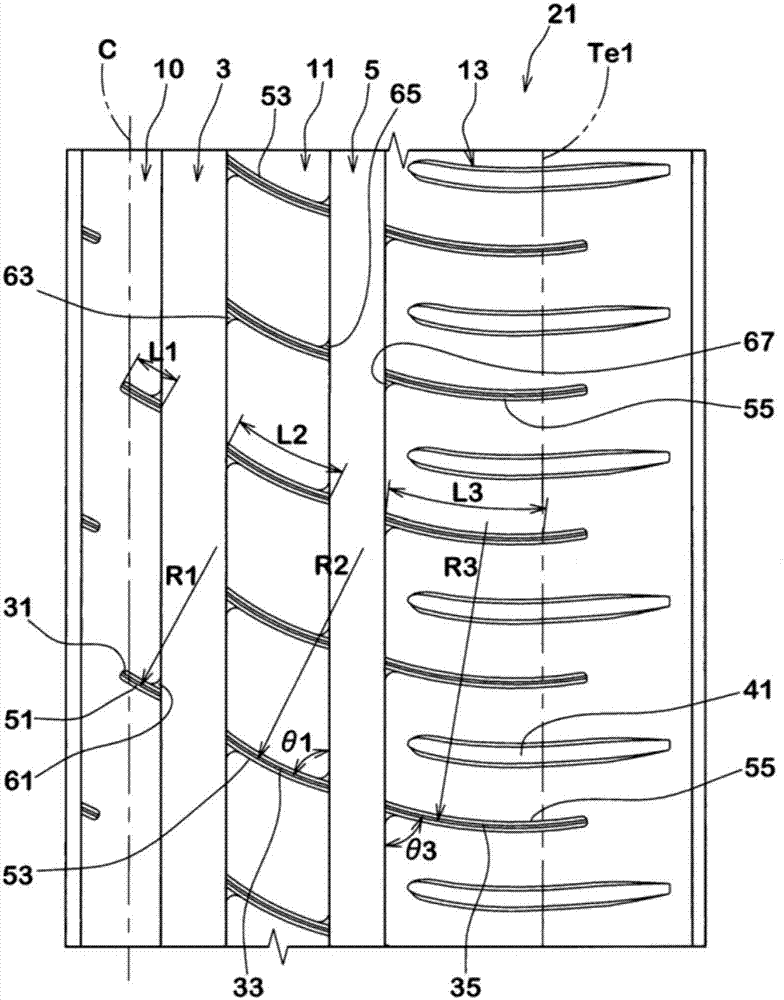

[0121] Prototyped according to the specifications in Table 1 with figure 1 The basic tread pattern is a pneumatic tire of size 215 / 60R16, and the handling stability performance is tested. The test method is described below.

[0122]

[0123] The test tire installed on the rim of 16×7.0J is installed on the all-wheel of a FR car with a displacement of 2500cc under the condition of an internal pressure of 250kPa, and a driver drives the test route on a dry asphalt road, and passes the test. The driver's senses were used to evaluate characteristics related to grip performance, steering wheel feel, and responsiveness. The results are represented by a score of 100 in Example 1, and the larger the numerical value, the better the steering stability performance.

[0124] [Table 1]

[0125]

[0126] As can be seen from Table 1, it can be confirmed that the pneumatic tires of the examples have intentionally improved steering stability performance compared with the comparative ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap