Method for controlling arc length at beginning as consumable electrode gas shielded welding

A technology of molten electrode gas and control method, which is applied in the direction of welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as fluctuations and poor welding quality, and achieve the effects of reducing burden, improving transition characteristics, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

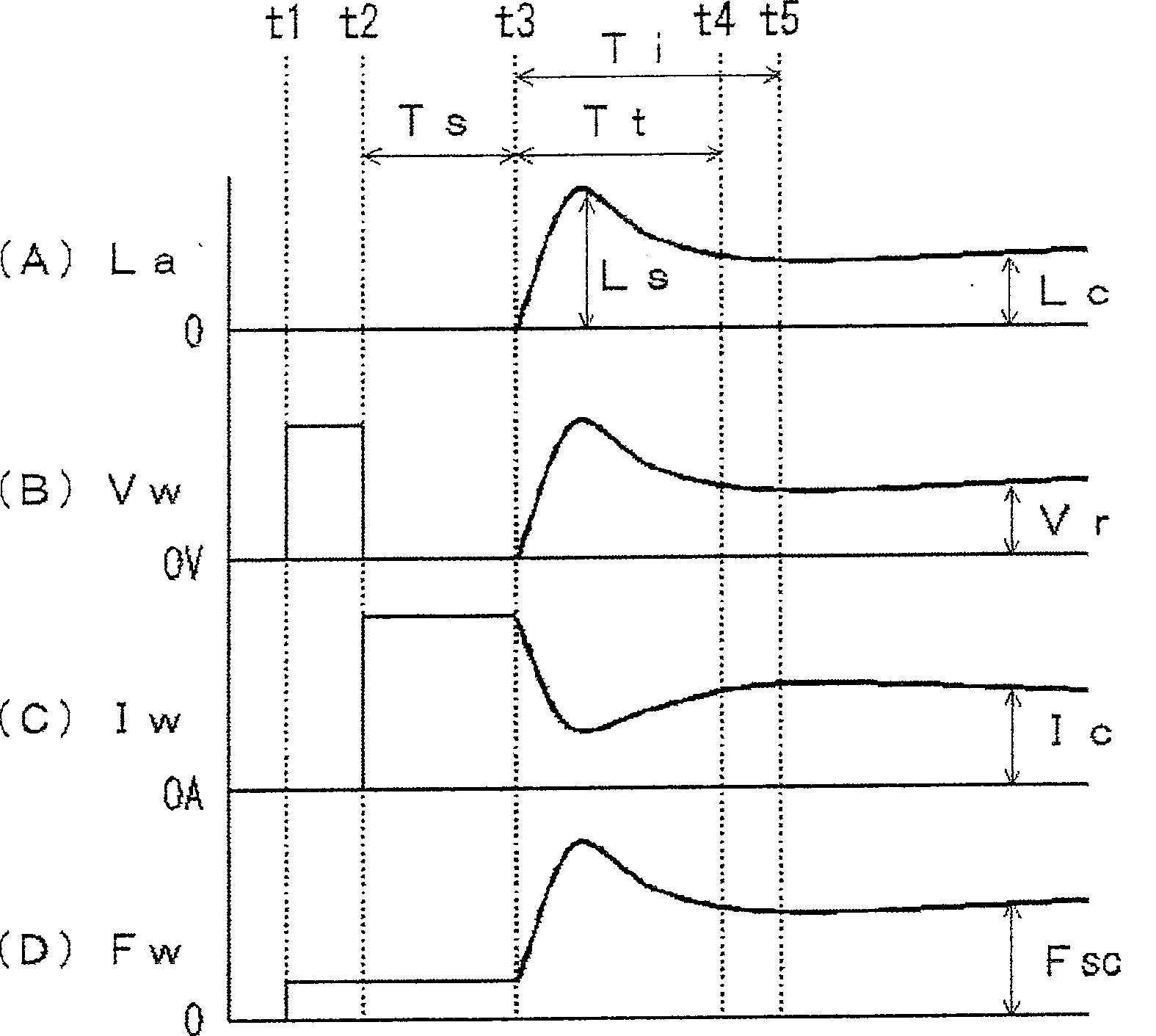

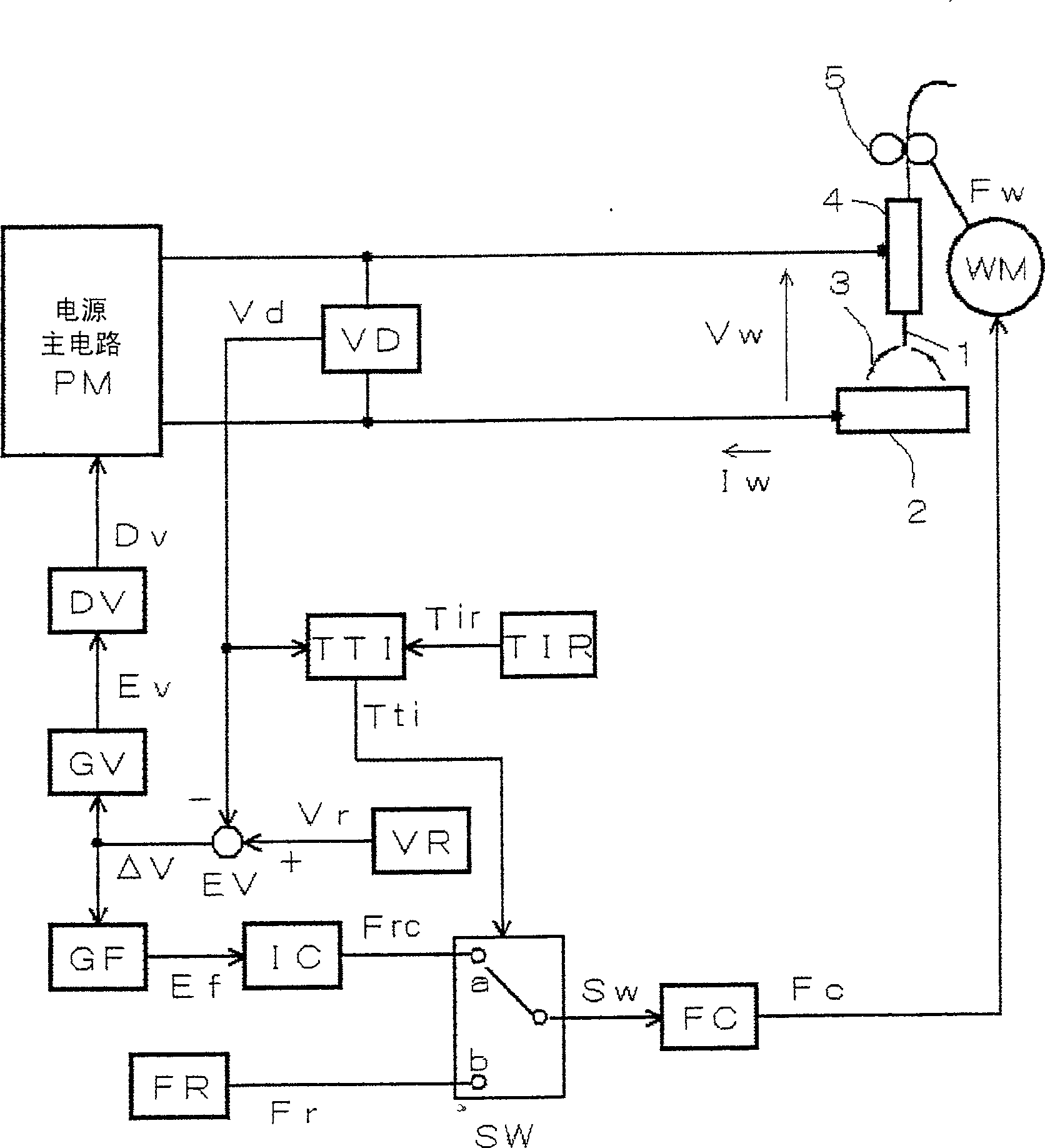

[0035] In Embodiment 1 of the present invention, during the predetermined initial period Ti after the arc is generated at the start of welding, the output control of the welding power supply device is performed so that the welding voltage value Vw and the voltage setting value Vr are approximately equal, and by performing The variable speed control of the welding wire feeding speed Fs quickly converges the arc length to an appropriate value, and after the initial period Ti passes, the welding wire feeding speed is set to a predetermined constant feeding speed Fsc, and the output control of the welding power supply unit , to maintain the arc length at an appropriate value. That is, the feedback control is performed on the voltage error ΔV=Vr−Vw between the voltage setting value Vr and the welding voltage value Vw, and the output control of the welding power supply device and the speed change control of the wire feeding speed Fs are performed simultaneously. Hereinafter, descrip...

Embodiment approach 2

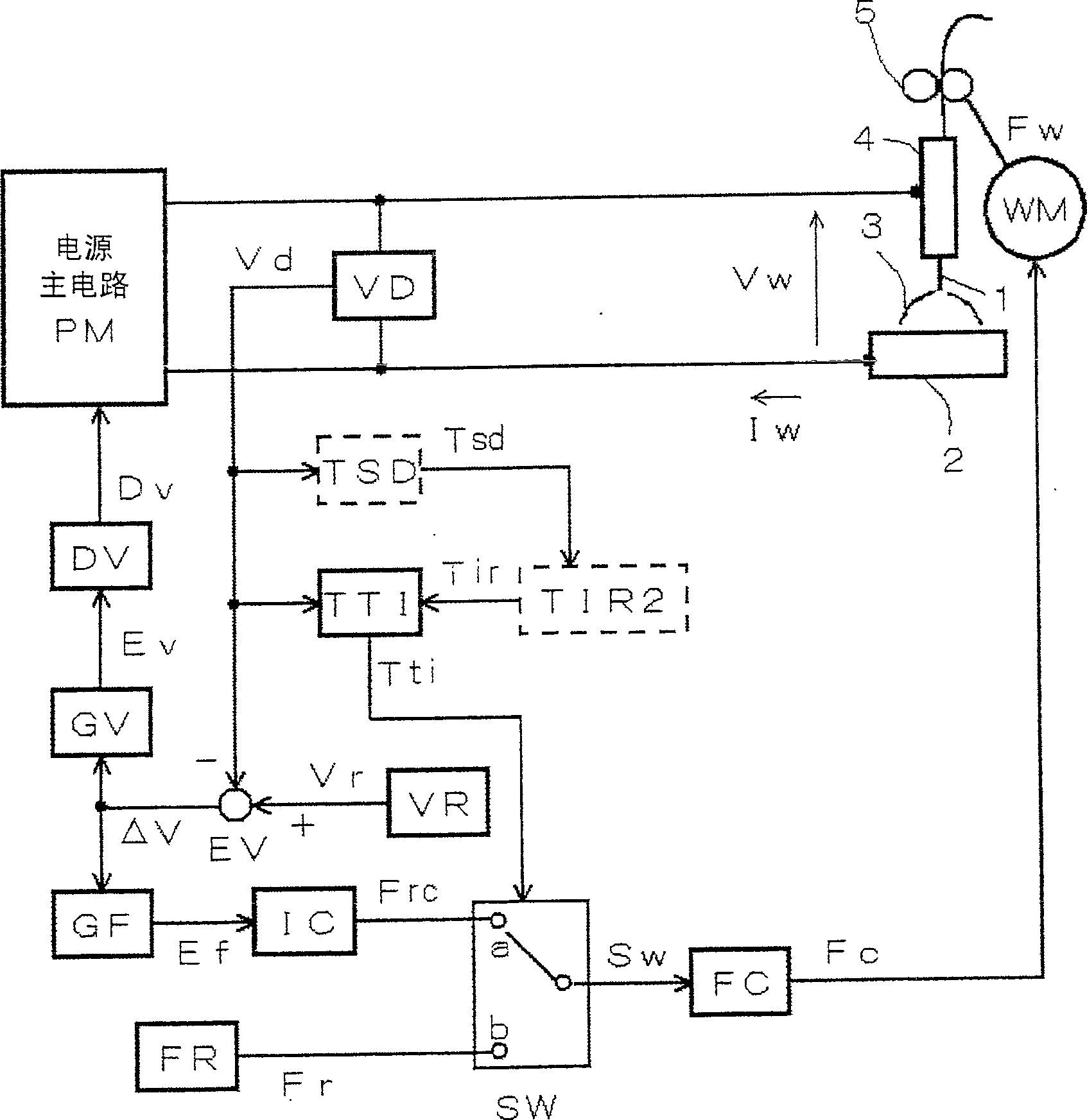

[0045] In the second embodiment of the present invention, in the first embodiment described above, the initial period Ti is changed according to the length of the short-circuit period Ts between the welding wire and the base metal at the start of welding. This is because, as described above, at the start of welding, a typical case where the arc length immediately after arc generation is extremely long is the case where the short-circuit period Ts described above is a long-term short-circuit. In addition, the initial arc length changes according to the time length of the short-circuit period Ts at the start of welding, and as a result, the transition period changes. Therefore, by changing the initial period Ti according to the length of the short-circuit period Ts, it is possible to instantly switch to the arc length control corresponding to the constant state when the arc length converges to a constant state. That is, since the feed variable speed control imposes a load on the...

Embodiment approach 3

[0051] In Embodiment 3 of the present invention, in Embodiment 1 or 2 described above, the wire feed speed Fs determined by the feed shift control in the initial period Ti is limited within a predetermined limit range W. The reason for this is that the wire feeding speed Fs is greatly changed by the wire feeding speed change control based on the voltage error in the initial period Ti. On the other hand, if the change value exceeds the specified range, there may be cases where the arc state becomes unstable due to the wire feeding speed Fs becoming too fast or too slow. Thus, by limiting the wire feed speed Fs determined by the feed variable speed control within a predetermined limit range W, the arc state can be prevented from being unstable. The limit range W is set to a value range that hardly affects the improvement effect of the arc length transition characteristic which is the object of the present invention. Hereinafter, description will be made with reference to the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com