A kind of acid-resistant pullulan derivative and preparation method thereof

A pullulan polysaccharide and derivative technology, applied in the chemical industry, can solve problems such as easy dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

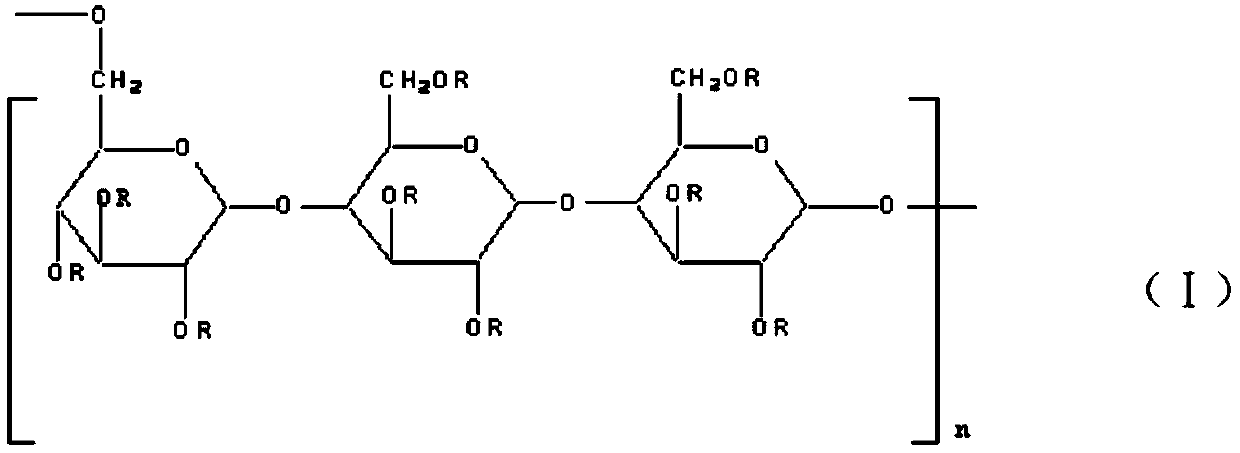

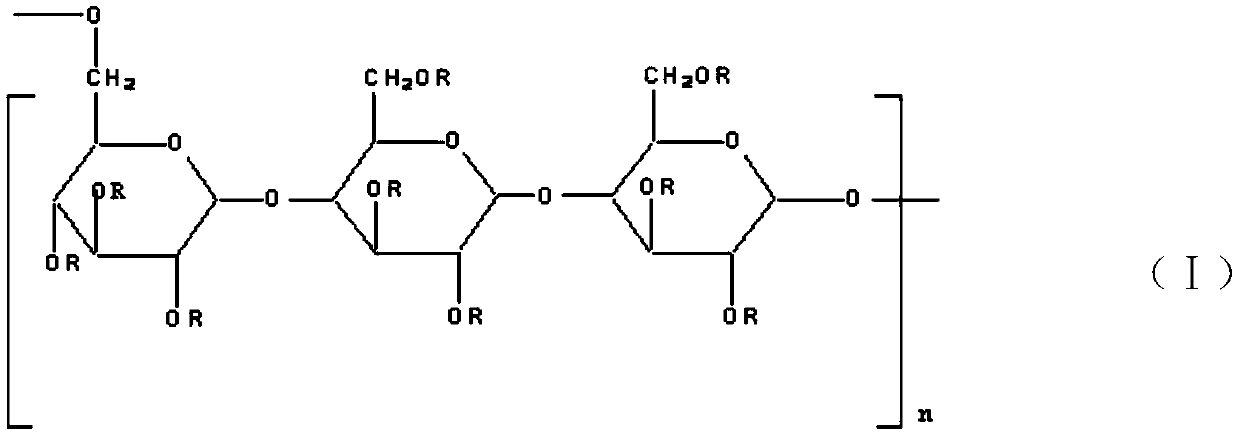

Method used

Image

Examples

Embodiment 1

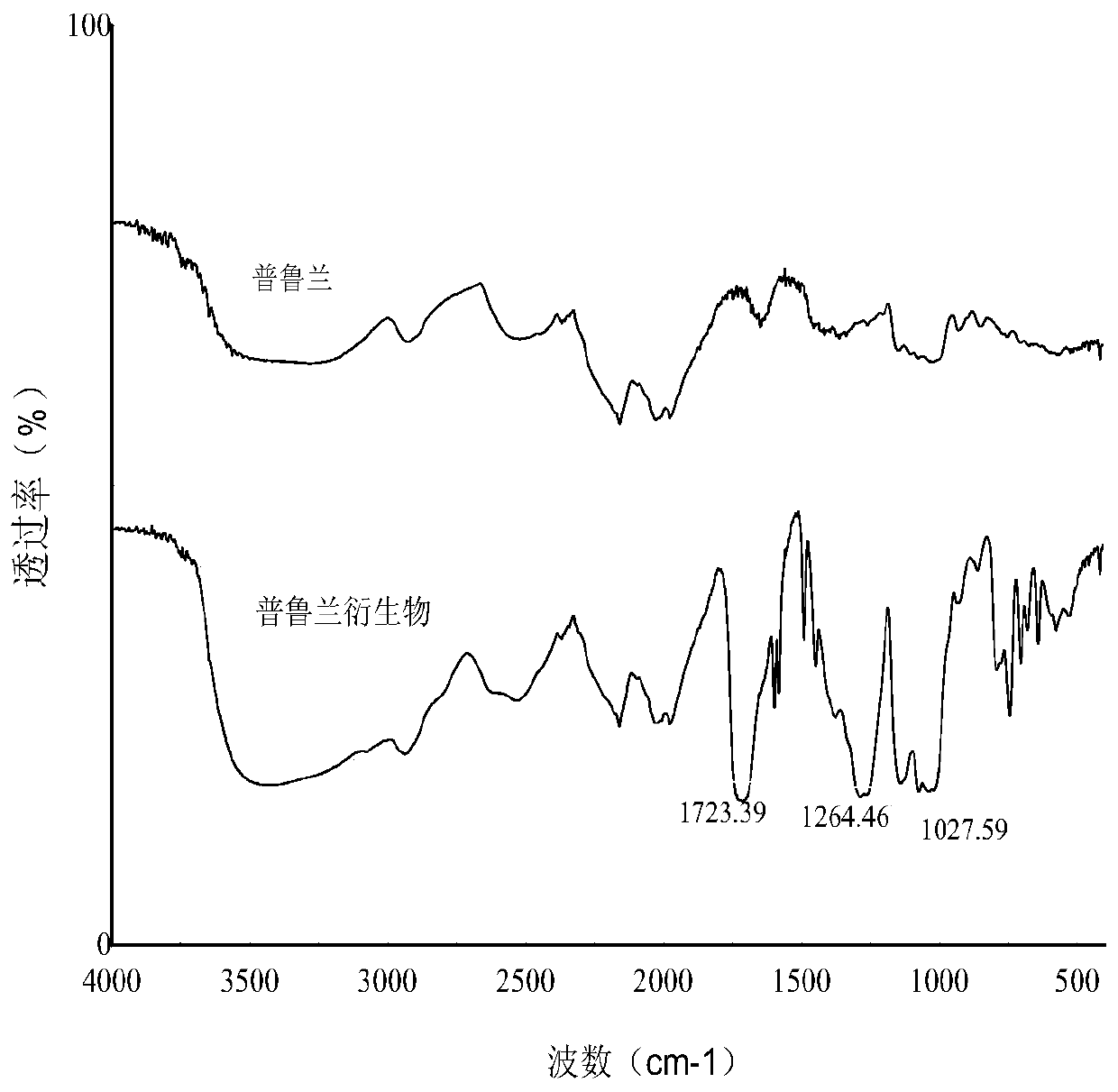

[0029] 15g pullulan, 30g phthalic anhydride, 55g pyridine, 105ml N,N-dimethylformamide. When the temperature rose to 80°C, the reaction time was started for 12 hours. After the reaction was completed, the reaction solvent was evaporated in a vacuum rotary, and the product was poured into ice water for washing. Wash repeatedly until the washing solution is neutral. Filter to obtain wet product, freeze-dry to obtain product. The structural infrared characterization of the product is as follows figure 1 As shown, the mass percentage of formyl benzoate is 35%, and the pullulan derivative remains intact at low pH (pH=1.5-4), and dissolves at higher pH (pH=5-7).

Embodiment 2

[0031] 15g pullulan, 10g phthalic anhydride, 25g pyridine, 35ml N,N-dimethylformamide. When the temperature rose to 50°C, the reaction time was started for 48h. After the reaction was completed, the reaction solvent was evaporated in a vacuum rotary, and the product was poured into ice water for washing. Wash repeatedly until the washing solution is neutral. Filter to obtain a wet product, and dry at 40°C to obtain a product. The mass percentage of formyl benzoate is 21%, and the pullulan derivative remains intact at low pH (pH=1.5-4.5), and dissolves at higher pH (pH=5-7).

Embodiment 3

[0033] 15g pullulan, 70g phthalic anhydride, 200g triethylamine, 250ml N,N-dimethylformamide. When the temperature rose to 60°C, the reaction time was started for 24h. After the reaction, the reaction solvent was evaporated in a vacuum rotary, and the product was poured into ice water for washing. Wash repeatedly until the washing solution is neutral. Filter to obtain wet product, freeze-dry to obtain product. The mass percentage of formyl benzoate is 65%, and the pullulan derivative remains intact at low pH (pH=1.5-5), and dissolves at higher pH (pH=5-7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com