Multi-station grid winding device

A winding device, multi-station technology, applied in the directions of woven fabrics, textiles and papermaking, can solve the problems of limiting the production efficiency of the knitting machine, the length of the grid roll, inconvenient to move and transport the grid roll, etc., and achieve a simplified structure. , Eliminate the limitation of width, the effect of rotation height synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and should not be used to limit the scope of protection of this patent.

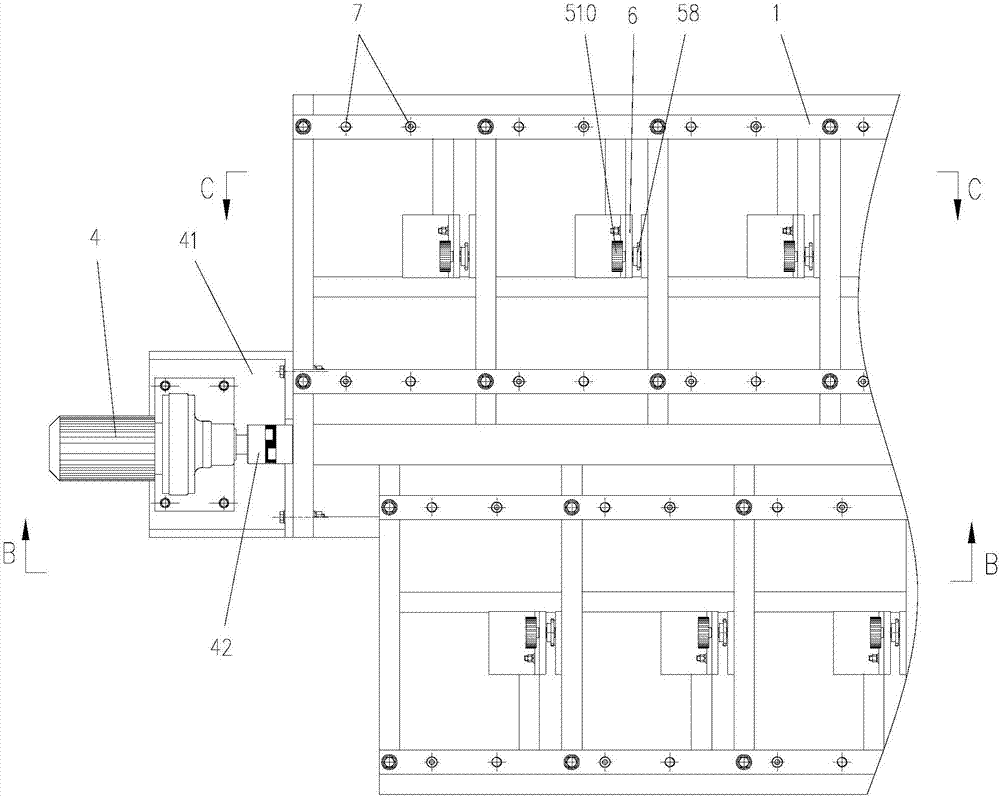

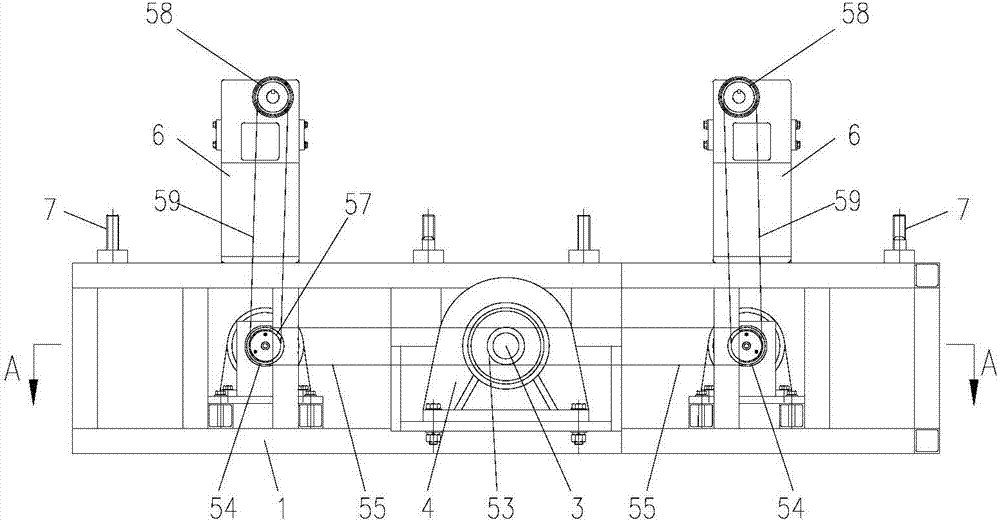

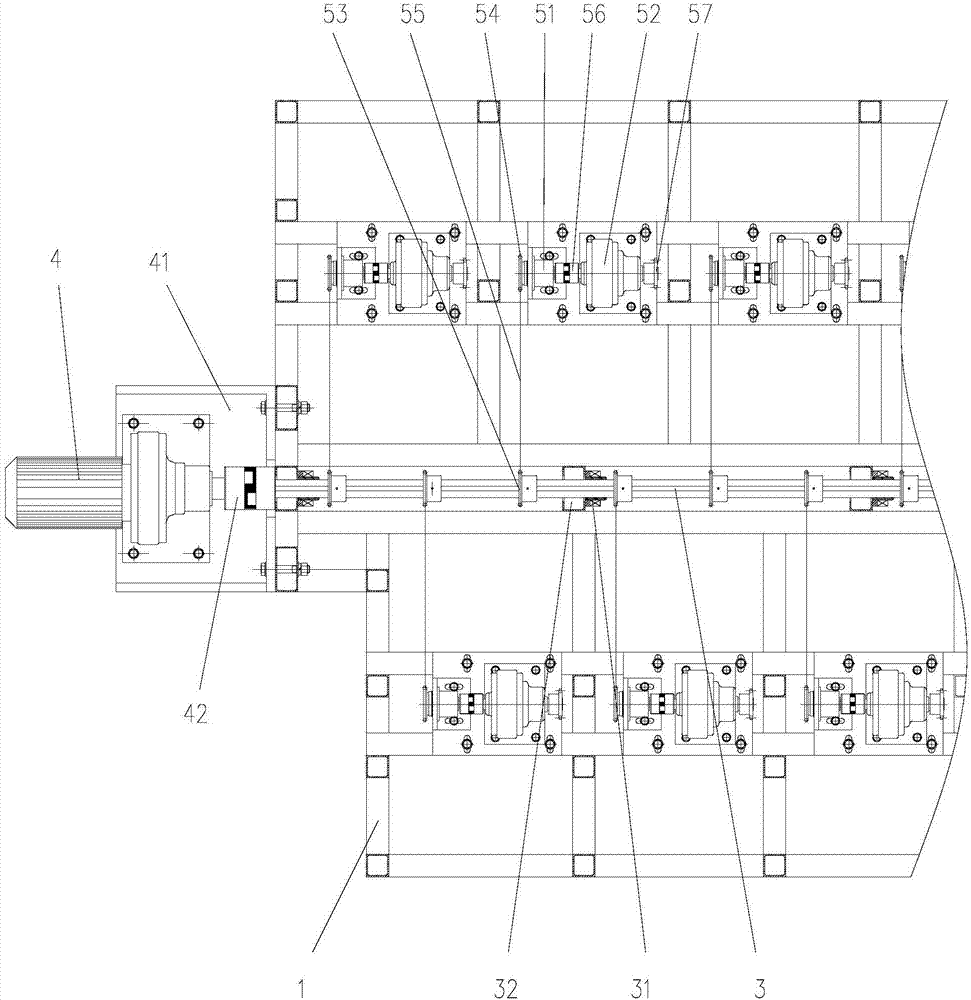

[0026] Such as Figure 1-Figure 7 As shown, the embodiment of the present invention provides a multi-station grid winding device, which includes a net collection chassis 1, and two rows of net collection components 2 are arranged on the upper side of the net collection chassis 1 opposite to each other. The assembly 2 is provided with at least one group of net collection assemblies 2, and the front row of net collection assemblies 2 and the rear row of net collection assemblies 2 are arranged in a staggered manner.

[0027] A horizontal main transmission shaft 3 is arranged on the net collection chassis 1 betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com