Electrical connectors and electrical connector assemblies

A technology for electrical connectors and contacts, applied in vehicle connectors, parts of connecting devices, connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

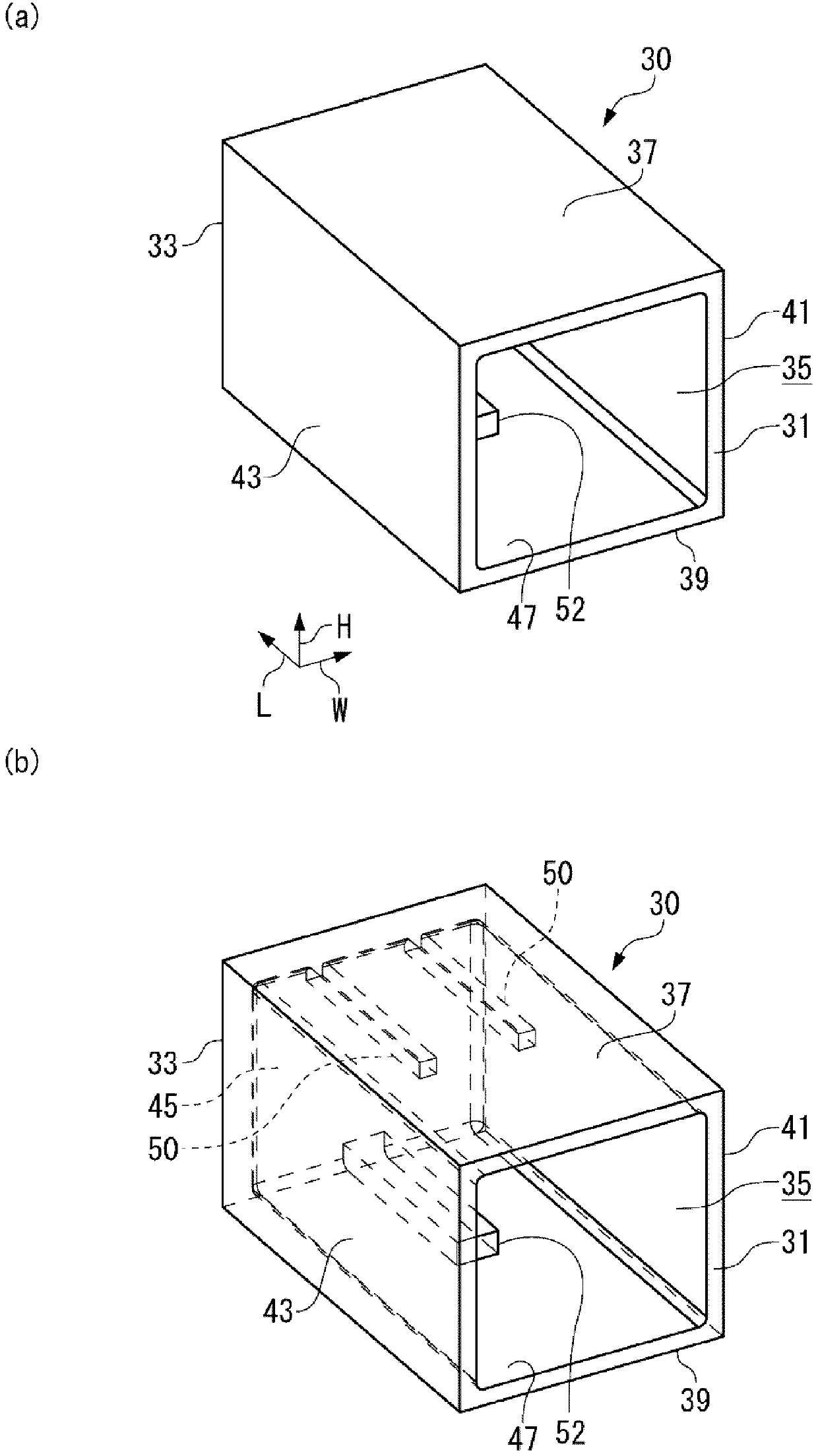

[0033] The electrical connector assembly 1 related to the first embodiment is as Figure 1 ~ Figure 3 As shown, a male housing 10 and a female housing 30 are provided. The male housing 10 constitutes the electrical connector (first electrical connector) of the present invention by holding a female contact (not shown), and the female housing 30 holds a male contact (not shown). The components are held to constitute the mating-side electrical connector (second electrical connector) of the present invention. When the male housing 10 and the female housing 30 are fitted together, the female contact and the male contact are electrically connected. Hereinafter, after describing the structure of the male housing 10 and the female housing 30 in order, the functions and effects of the electrical connector assembly 1 will be described.

[0034] [male housing 10]

[0035] The male housing 10 is a member obtained by injection molding a resin having electrical insulation properties, suc...

no. 2 approach

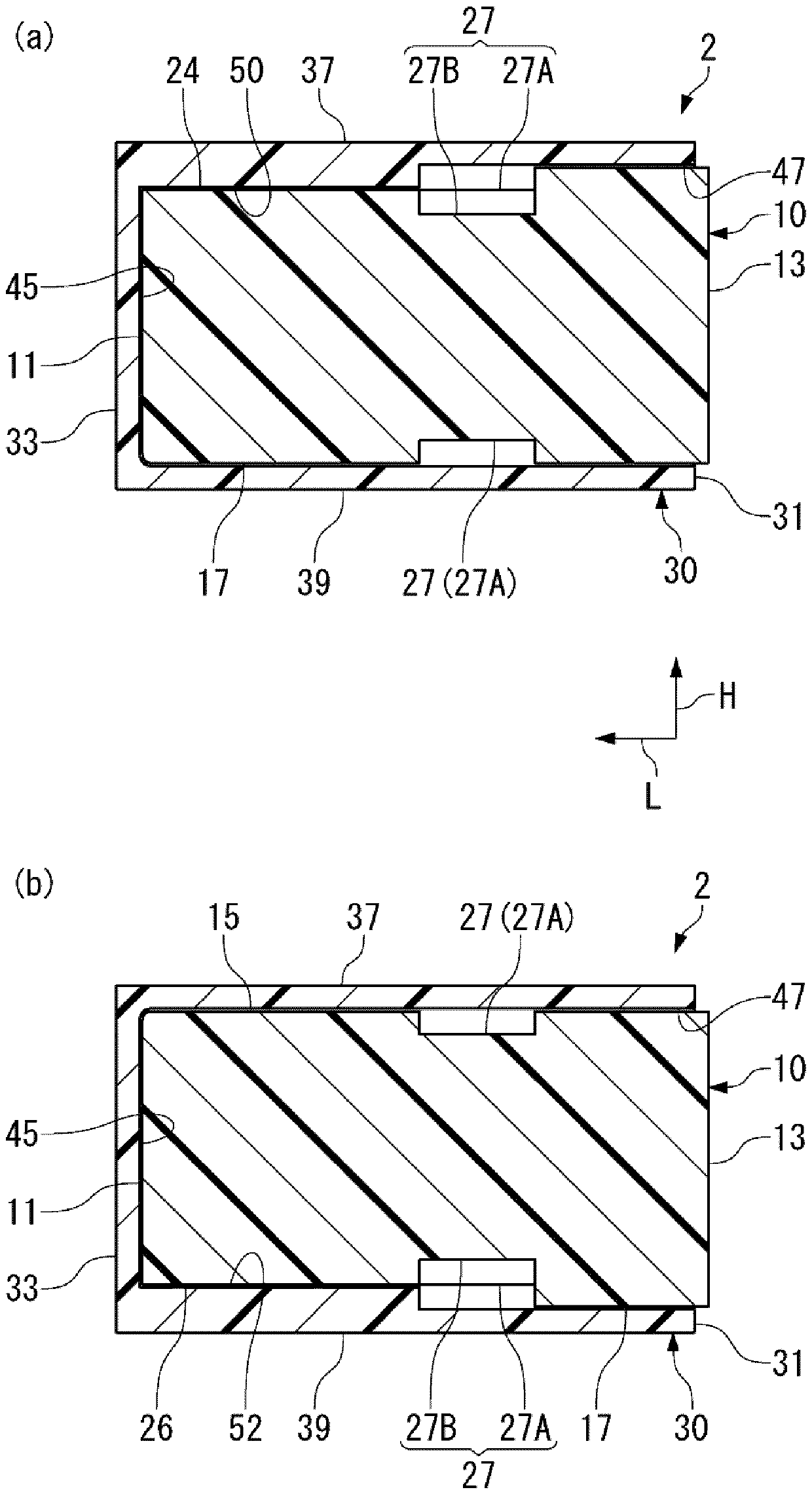

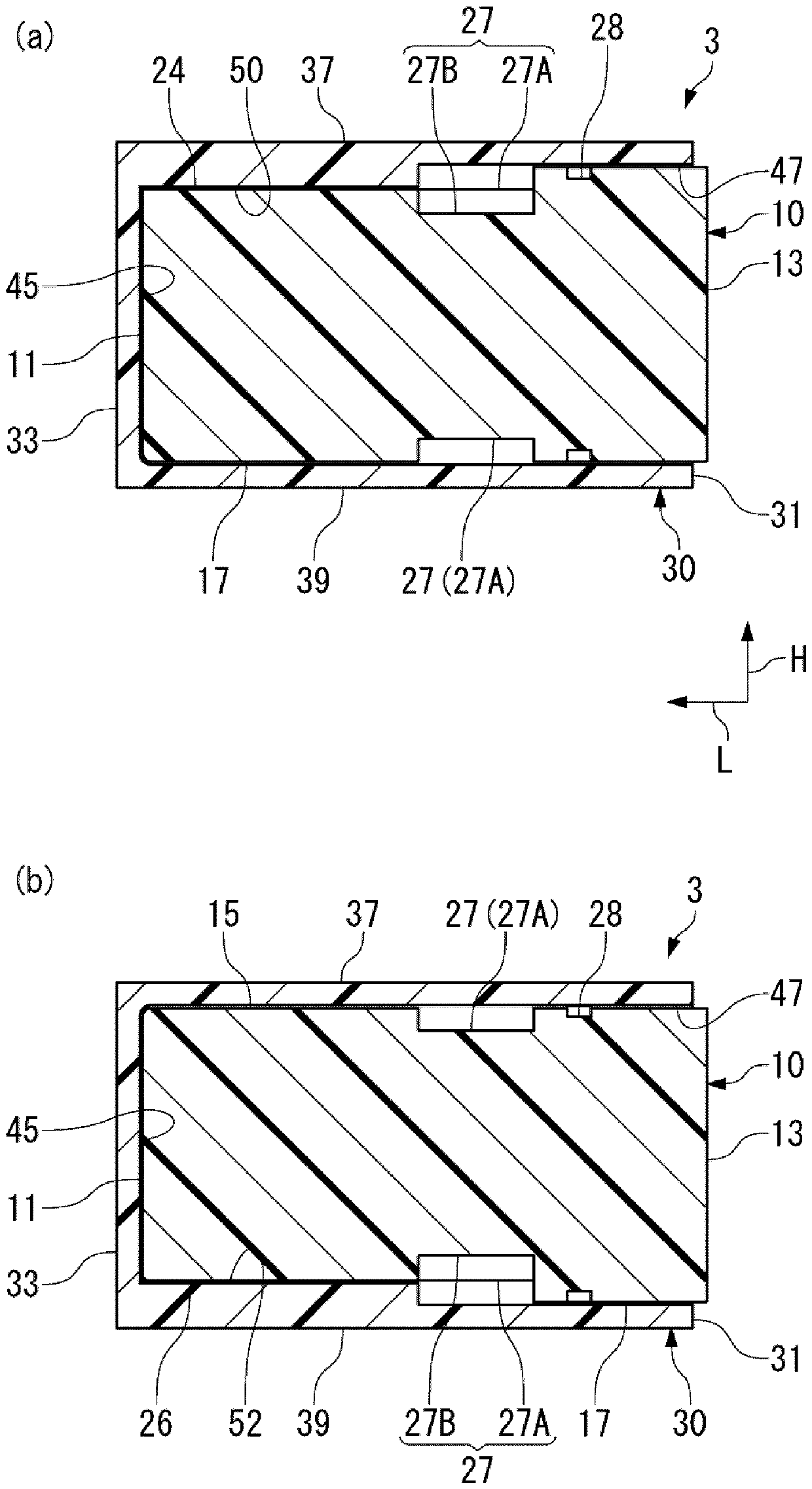

[0062] Next, refer to Figure 4 ~ Figure 6 The electrical connector unit 2 according to the second embodiment of the present invention will be described.

[0063] The electrical connector assembly 2 is consistent with the electrical connector assembly 1 in that a certain waterproof performance is ensured by setting the water stop groove 27 . However, in the electrical connector assembly 2 , the upper guide groove 24 , the lower guide groove 26 , the upper guide bar 50 , and the lower guide bar 52 are limited to the deeper side than the water stop groove 27 in order to improve the waterproof performance. In addition, in the electrical connector assembly 2, for the same elements as the electrical connector assembly 1, for Figure 4 ~ Figure 6 attached with Figure 1 ~ Figure 3 same symbols, and their descriptions are omitted.

[0064] Electrical connector assembly 2 such as Figure 6 (a), (b), in the male housing 10, a pair of upper guide grooves 24, 24 and lower guide groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com