Fuel filter comprising a filter insert with a prefilter element and a main filter element

A fluid filter and pre-filter technology, applied in filter plug-in, fuel or oil fields, can solve the problems of contamination, damage, fluid arrival, etc., and achieve the effect of compact structure, good separation, and reduced space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

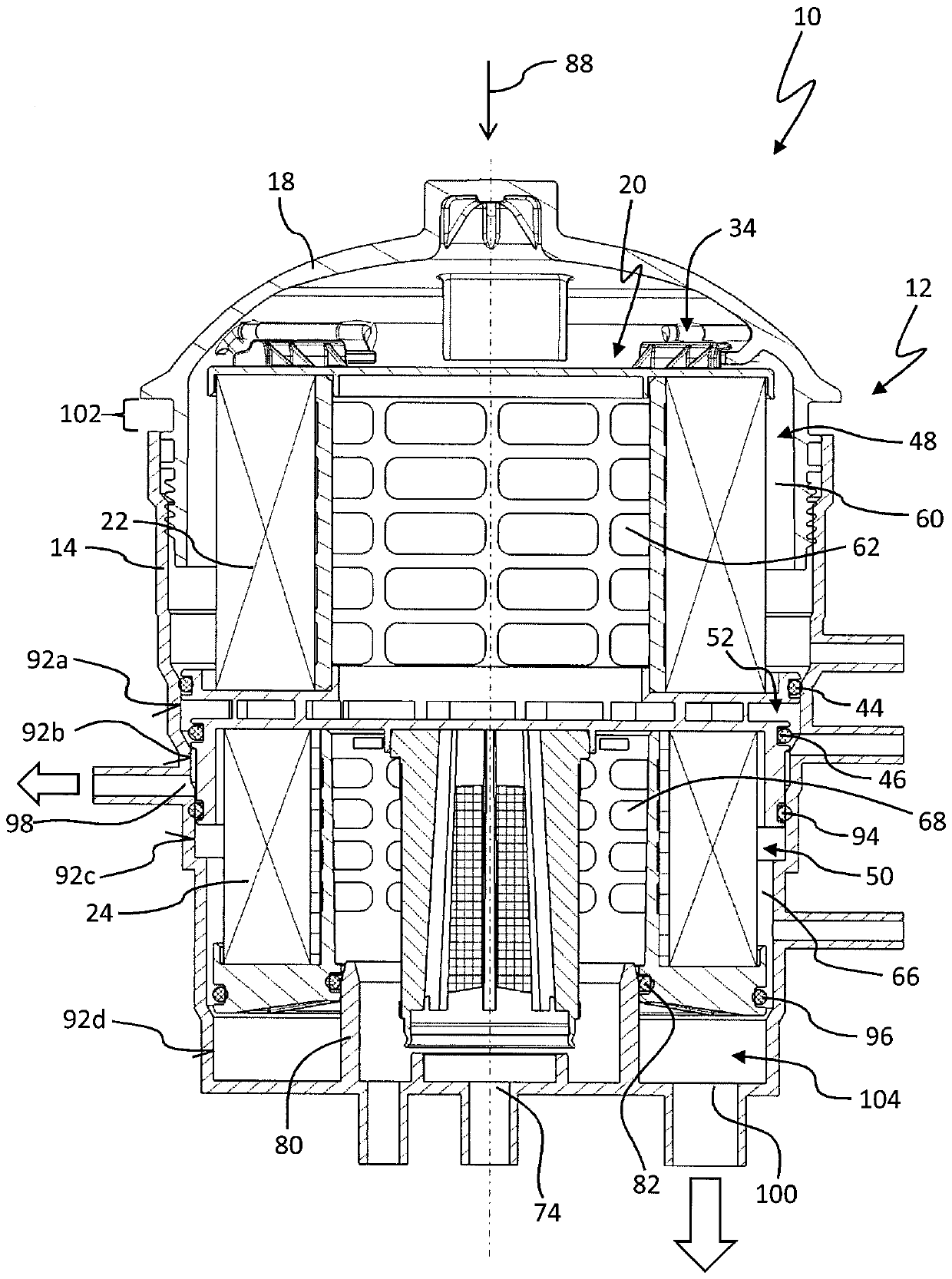

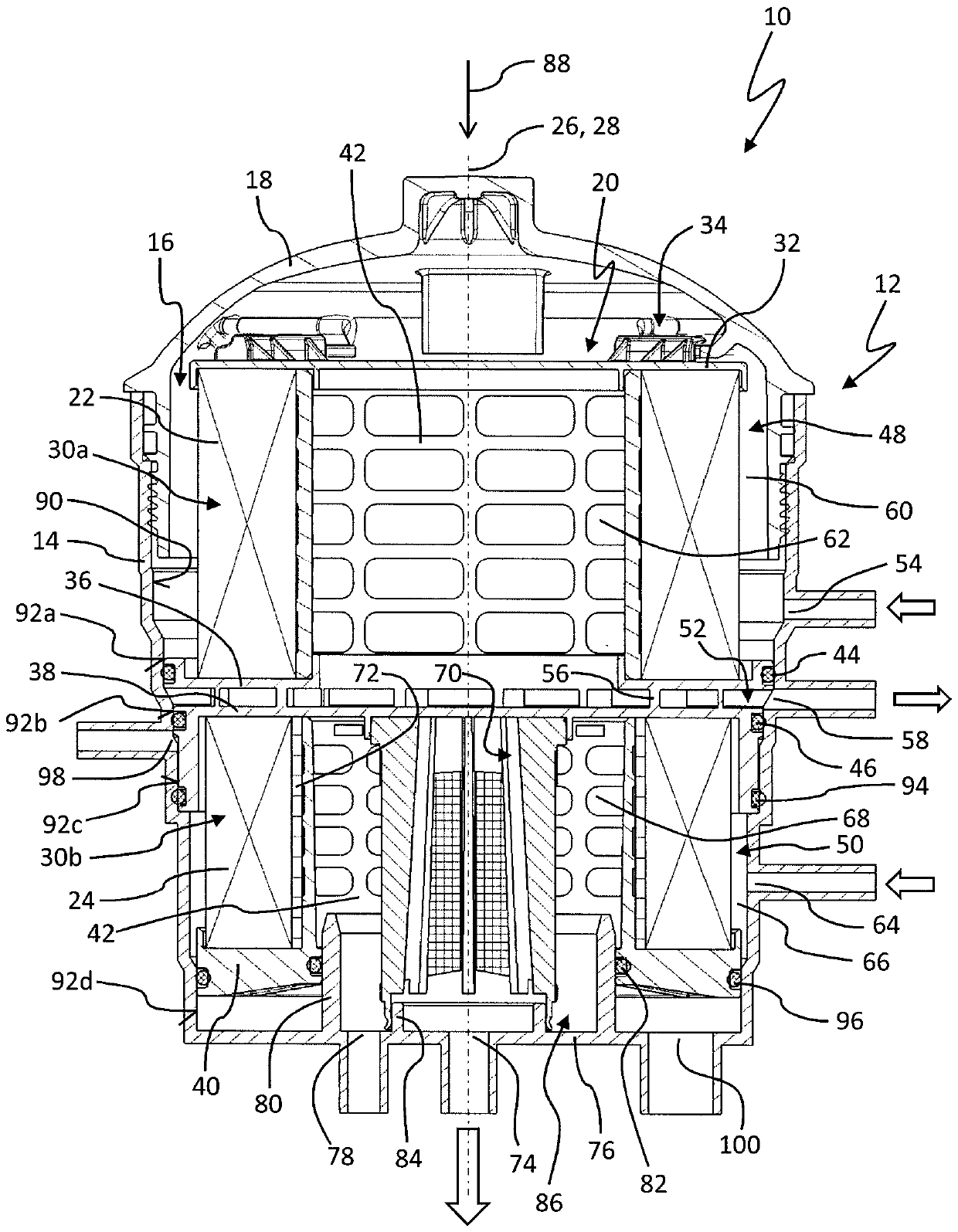

[0028] figure 1 A fluid filter 10 according to the invention is shown. Fluid filter 10 can be designed, for example, as a fuel filter for filtering out pollutants contained in fuel, in particular diesel fuel. Fluid filter 10 is suitable, for example, for use in motor vehicles with an internal combustion engine.

[0029] The fluid filter 10 comprises an openable filter housing 12 having a filter pot 14 with an insertion opening 16 and having a filter cover 18 for closing the filter pot 14 . The filter cap 18 may be screwed into the filter canister 14 . Another type of fastening of the filter cover 18 on the filter pot 14 is conceivable. The filter housing 12 can be produced, for example, from metal or from a plastic material.

[0030] A filter insert 20 is arranged exchangeably in the interior of the filter housing 12 . exist figure 1 Middle filter insert 20 is in the operating position in filter housing 12 , so that fluid filter 10 can be used in separate operation. Fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com