An automatic storage robot system

A robot system and automatic technology, applied in the field of warehousing systems and automated warehousing systems, can solve the problems of easy loss, storage equipment and systems do not have automation functions, and low site utilization, achieving a simple and reliable working principle and improving site utilization. , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

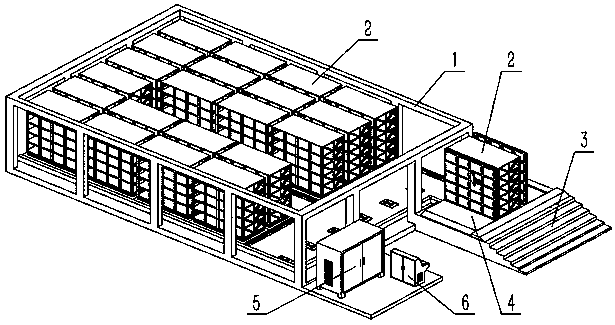

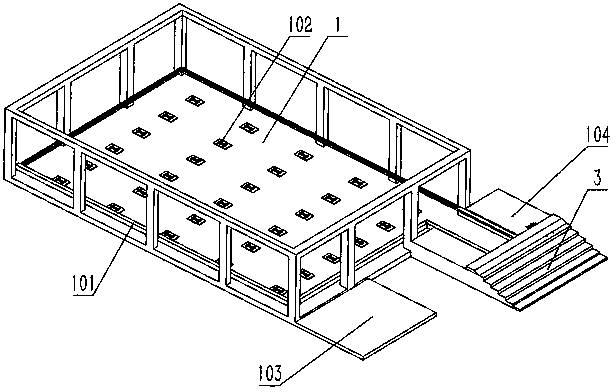

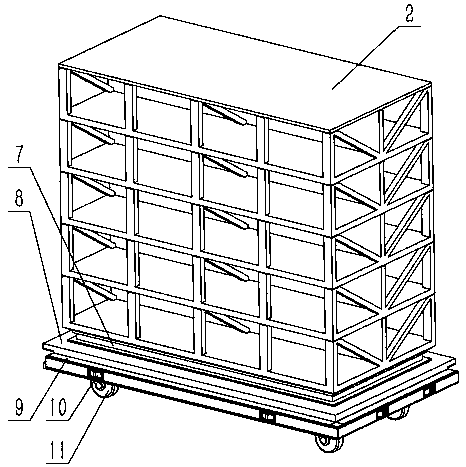

[0020] like Figure 1 to Figure 7 As shown, an automatic storage robot system includes a frame 1, a transport trolley, two safety doors 4, a safety power distribution system 5 and a main control system 6. The left side of the front of the frame 1 is set as the control area 103, and the safety power distribution system 5 and the main control system 6 are set in the control area 103, and the right side of the front of the frame 1 is set as the loading and unloading area 104, and the front of the loading and unloading area 104 is equipped with a walking ladder 3. An insulating guide rail 101 is provided on the inner edge of the frame 1 , and frame conductive strips are provided on the insulating guide rail 101 . Seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com