Oil emptying support

A support frame and oil tank technology, applied in emptying containers, bottle filling, packaging, etc., can solve the problems of wasting manpower and time, and achieve the effects of saving time, manpower and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

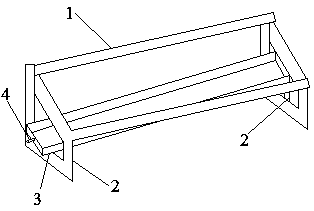

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] An oil control bracket, which is characterized in that it includes an oil drum support frame and an oil tank, and the oil drum support frame is composed of several horizontal load-bearing rods arranged in parallel and fixed frames connected and fixed at both ends of the horizontal load-bearing rods. There is an oil tank arranged obliquely, the two ends of the oil tank are fixed on the fixed frame, and the lower end of the oil tank is provided with an oil outlet. A plurality of connecting and fixing rods are arranged at intervals on the lateral bearing rods. An anti-skid leather pad is provided on the transverse bearing bar.

[0014] When in use, the outlets of multiple oil barrels are placed on the transverse bearing bar downwards, and the outlets of the oil barrels are aligned with the oil tank. Non-slip leather pads prevent the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com