Parameter optimizing method of high-speed hollow cylindrical roller bearing

A technology of hollow cylinder and roller bearings, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., and can solve the problems of large calculation errors of fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

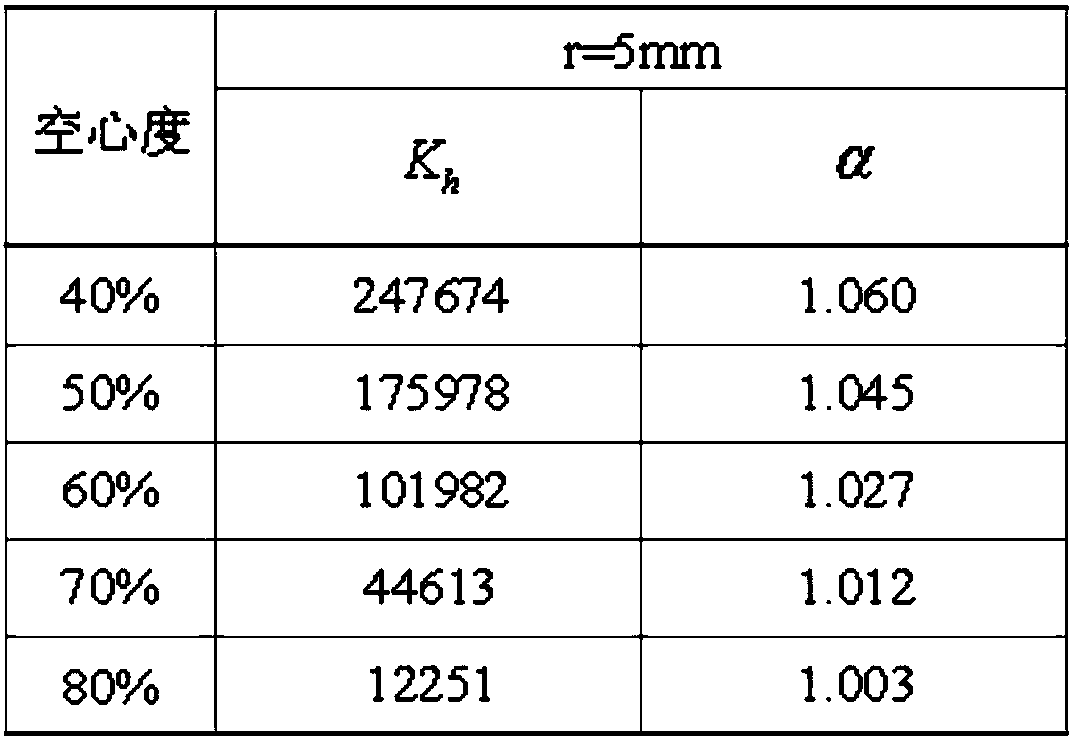

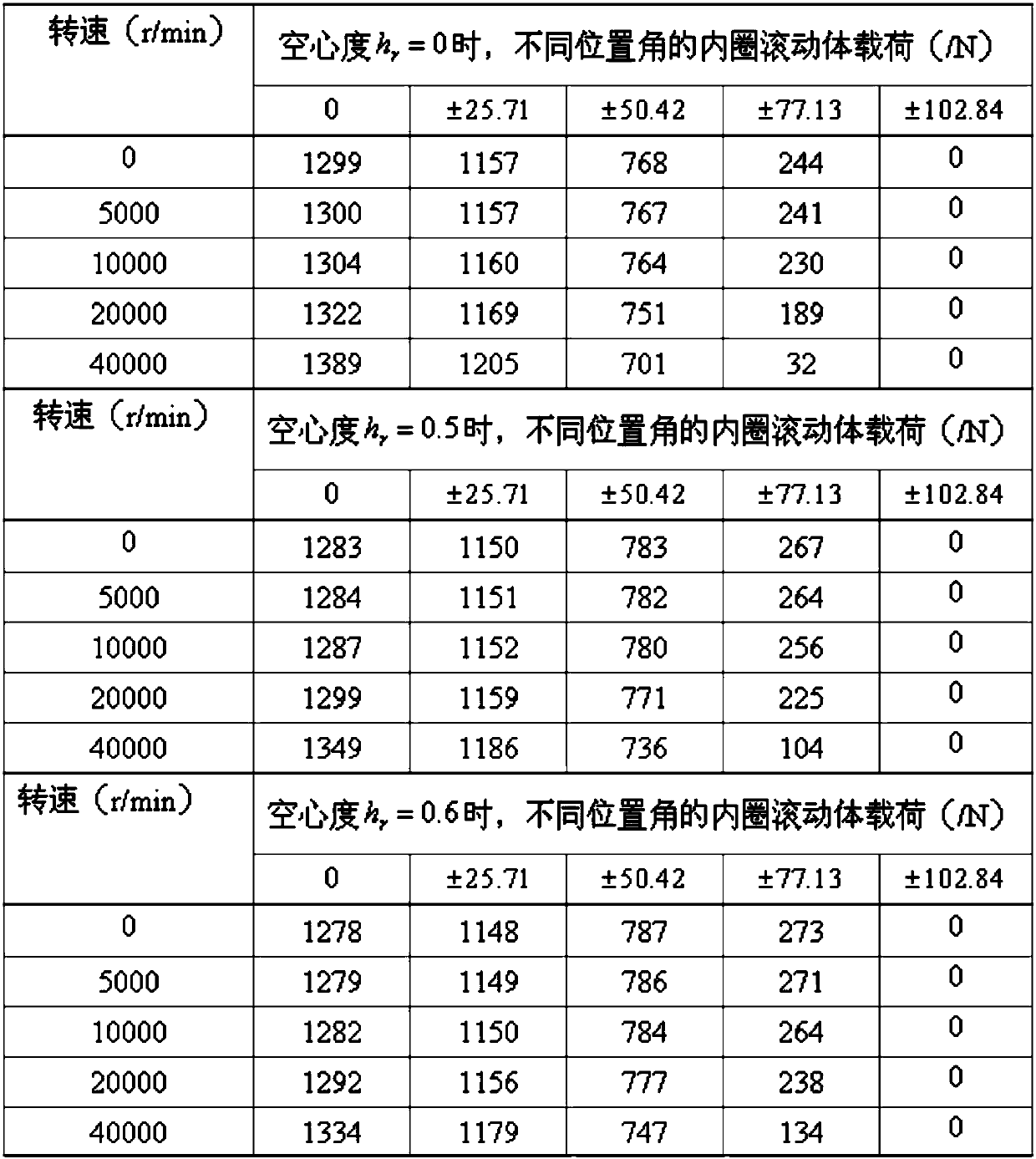

[0126] Bearings are standard parts, and its optimized design is more meaningful only for a certain type of bearing. Therefore, according to the working conditions, the working speed of the bearing is determined to be 4000r / min, and the expected fatigue life of the bearing is 1800×10 6 r. The basic parameters of a certain type of bearing used in this example are: inner ring raceway radius R i =27.5mm, outer ring raceway radius R o =37.5mm, the number of rolling elements Z=14, the radius of rolling elements r=5mm, the effective length of rolling elements l=9.6mm.

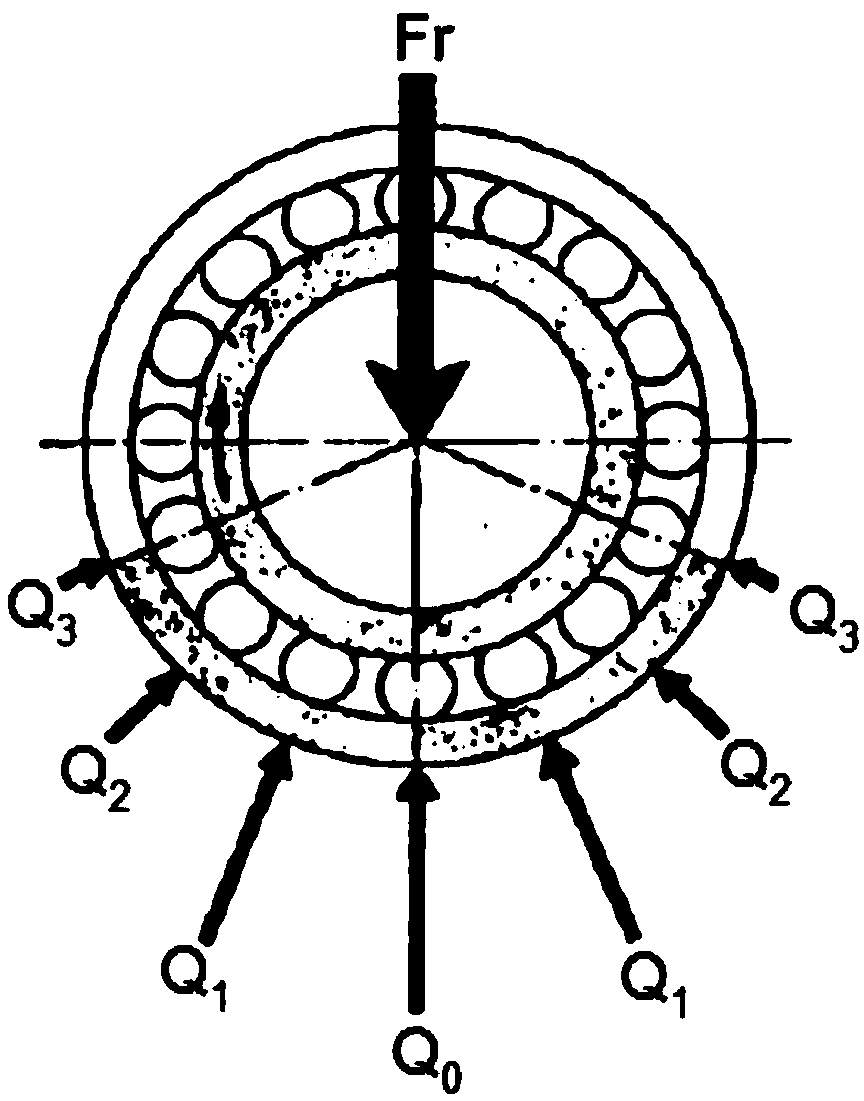

[0127] figure 1 A schematic diagram of the load distribution of a cylindrical roller bearing.

[0128] figure 2 It is the contact stiffness and deformation index of the hollow cylindrical roller with a radius of r = 5mm and the ring at different hollow degrees. pass figure 2 From the calculation results in , it can be clearly found that the contact stiffness and load deformation index between the hollow cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com