Zisha ceramsite, preparation method and application of zisha ceramsite and filling wine

A purple sand pottery and filling technology, which is applied in the preparation and application of alcoholic beverages, ceramic products, etc., can solve the problems of affecting the quality of the wine body, slow aging and other problems, achieve a significant catalytic effect, prevent hydrolysis, and accelerate aging The effect of aging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

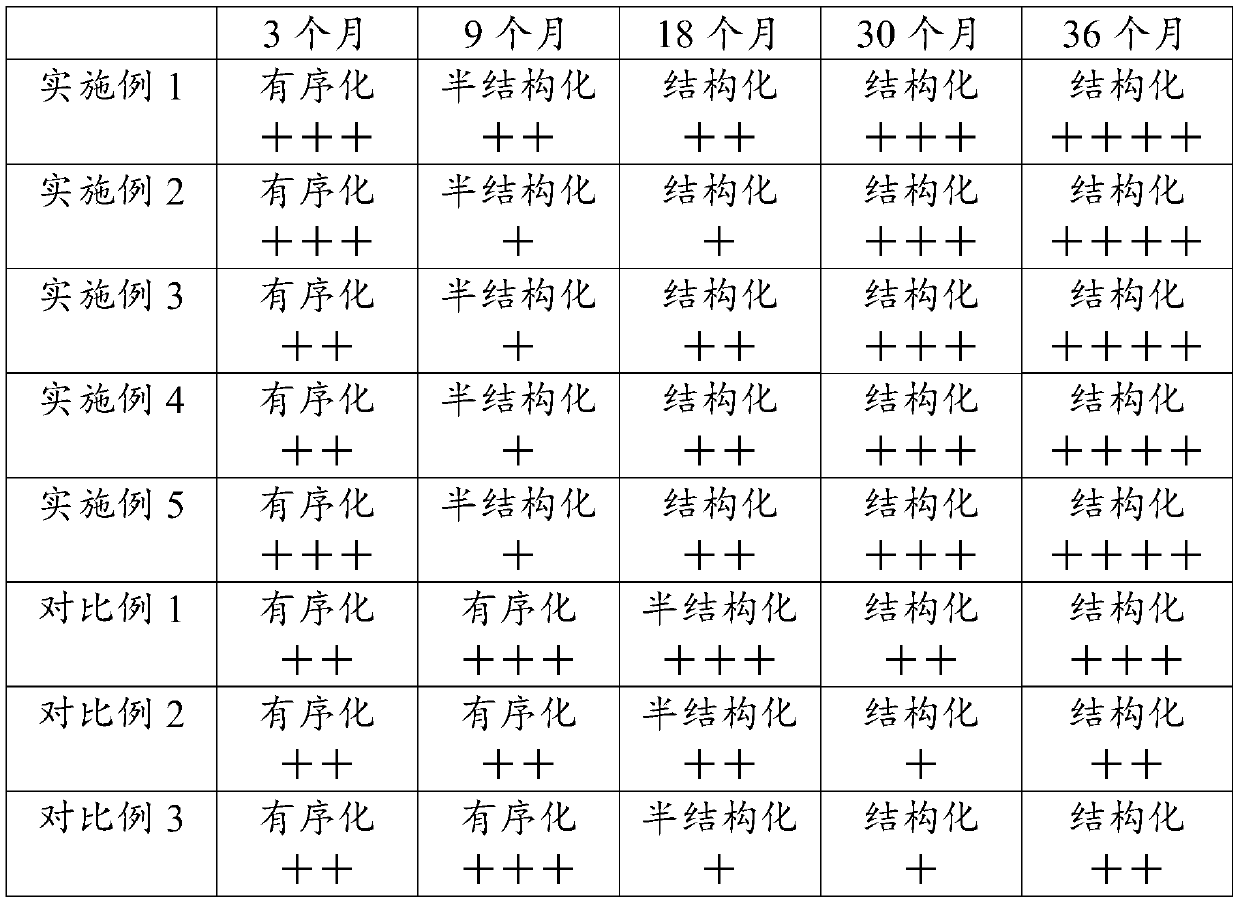

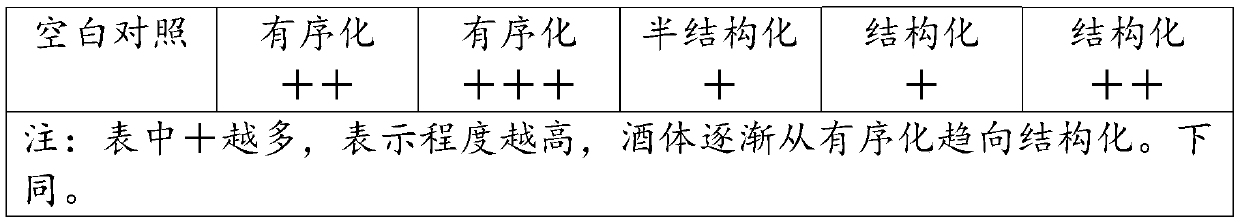

Examples

preparation example Construction

[0055] According to the second aspect of the present invention, the embodiment of the present invention provides a method for preparing the above-mentioned purple sand ceramsite, which includes the following steps: fully mixing the purple mud slurry with nano-silicon and nano-nickel in the formula, forming it, and then firing it into Zisha ceramsite.

[0056] The preparation method of purple sand ceramsite provided by the embodiment of the present invention fully mixes purple mud, nano-silicon and nano-nickel to form it, and then fires it. It has the advantages of simple operation steps, easy production, and high product qualification rate, and finally can obtain properties. The uniform and stable purple sand ceramsite product is suitable for large-scale production and popularization. The purple sand ceramsite prepared by the preparation method provided by the embodiment of the present invention conforms to GB / T10816-2008 "National Standard for Zisha Pottery" after testing, an...

Embodiment 1

[0076] A purple sand ceramsite comprises the following raw materials in terms of mass percentage: 0.001% of nano-silicon, 0.001% of nano-nickel, and 99.998% of purple mud; the purple mud includes purple sand mud and water with a mass ratio of 1:1.2.

[0077] The preparation method of purple sand ceramsite comprises the steps:

[0078] Mix the purple mud with nano-silicon and nano-nickel thoroughly and form it, and then fire it at 1200°C for 12 hours to obtain the purple sand ceramsite product.

Embodiment 2

[0080] A purple sand ceramsite comprises the following raw materials in terms of mass percentage: 0.0005% of nano-silicon, 0.0015% of nano-nickel, and 99.998% of purple mud; the purple mud includes purple sand mud and water with a mass ratio of 1:1.5.

[0081] The preparation method of purple sand ceramsite comprises the steps:

[0082] The purple mud is fully mixed with nano-silicon and nano-nickel, and then molded, and fired at 1000°C for 14 hours to obtain a purple sand ceramsite product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com