Advanced processing control for technology sensing dimension target

A technology with process and target characteristics, applied in the field of advanced process control, which can solve the problems that the adjustment of process specifications is not optimal, and the characteristics cannot be represented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

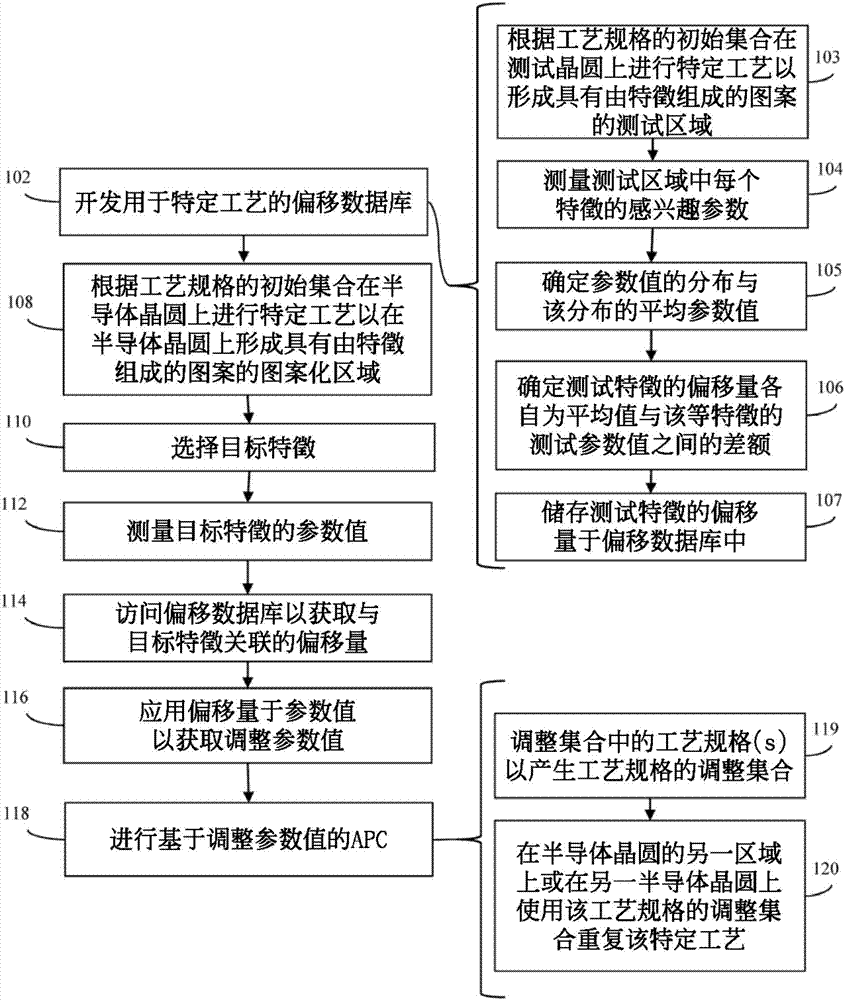

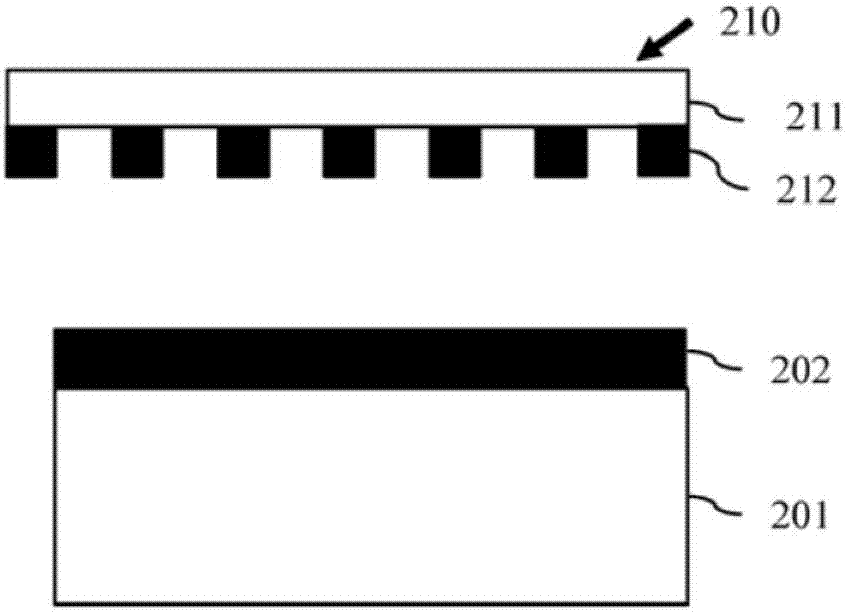

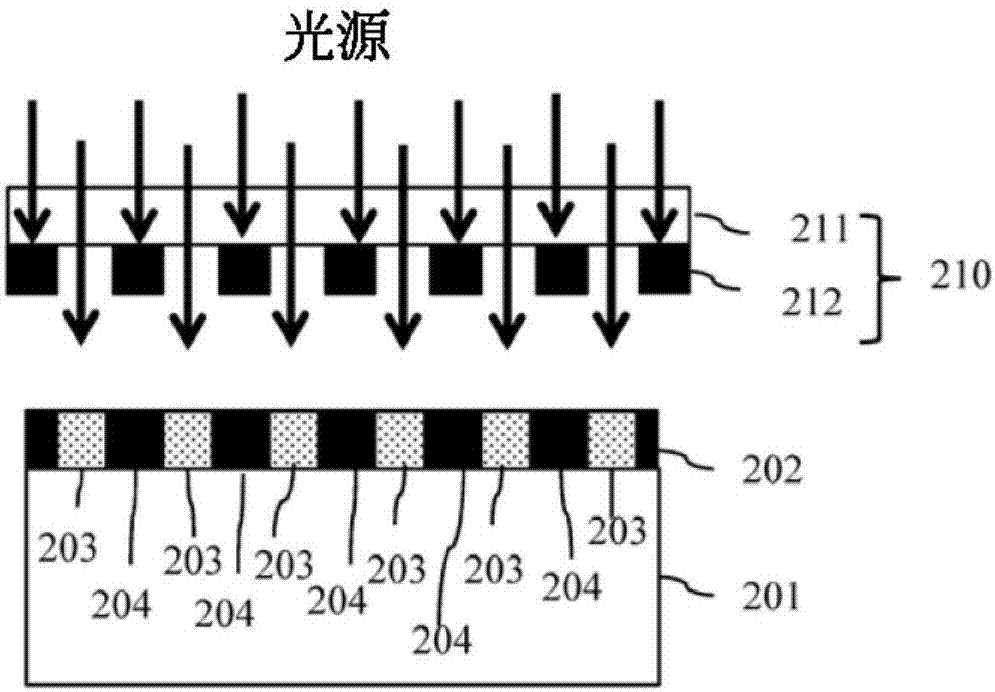

[0022] As mentioned above, in semiconductor wafer processing, advanced process control (APC) refers to the selective adjustment of one or more process specifications of a particular process based on feedback so that the process can be repeated on the same semiconductor wafer or on different semiconductor wafers. At a particular process, the target parameter value for each of its multiple instances is achieved for the same feature in the pattern. For example, certain processes (eg, photolithography or etching processes) used to form a patterned region on a semiconductor wafer with a pattern of several features (eg, more than 200 features) can perform APC. In particular, APC may be performed when attempting to achieve target parameter values in each of the characteristics. For example, the target parameter value may be a key dimension. For purposes of this disclosure, the term "key dimension" refers to the minimum dimension of a feature (eg, the minimum width of a feature). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com