A method for optimizing top fluid pulse time in channel fracturing

A technology of pulse time and channel fracturing, which is applied in the direction of earthwork drilling, wellbore/well components, instruments, etc., can solve the problem that the pulse time of the sand-carrying fluid and the pulse time of the top fluid are not obtained separately, and achieve Reliable results, improved accuracy, and simple model effects

Active Publication Date: 2019-10-01

SOUTHWEST PETROLEUM UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method only obtains the pulse time in general, and does not separately obtain the pulse time of the sand-carrying liquid and the pulse time of the top liquid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

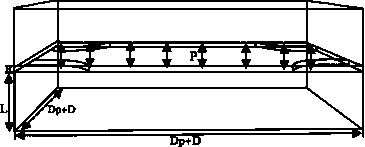

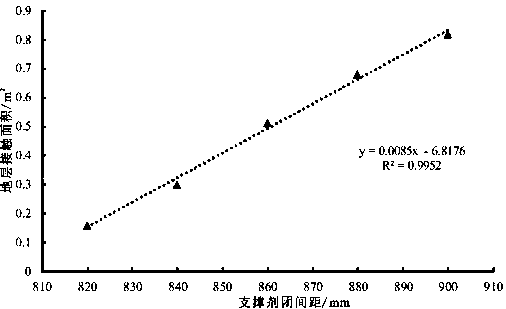

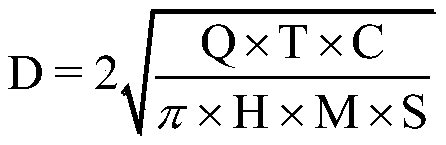

The invention discloses a method for optimizing the top liquid pulse time in channel fracturing, which comprises the following steps in sequence: (1) calculating the diameter of the proppant cluster formed in the fracture through on-site construction parameters; The diameter of the proppant group is combined with the elastic modulus E of the formation rock, the Poisson’s ratio υ of the formation rock, the thickness of the reservoir layer L and the formation closure pressure P, and the proppant group-formation contact finite element model is established in the ABAQUS software. Optimal laying distance Dp 1 ; (3) Combined with the optimal proppant group spacing Dp obtained in step (2) 1 , to calculate the top fluid pulse time in channel fracturing. The present invention considers the impact of formation closure pressure on the top liquid pulse time, combines the formation rock parameters and field construction parameters, obtains the top liquid pulse time through the sand-carrying liquid pulse time, and effectively solves the top liquid pulse time in the field construction process Undetermined question.

Description

technical field The invention relates to the field of petroleum exploration and development, in particular to a method for optimizing top fluid pulse time in channel fracturing in unconventional tight oil and gas reservoirs. technical background With the deepening of exploration and development of oil and gas resources, unconventional tight oil and gas reservoirs have become the focus of exploration and development. Due to the extremely low porosity and permeability, unconventional tight oil and gas reservoirs must rely on large-scale hydraulic fracturing to be effectively developed. Among them, channel fracturing is a new type of hydraulic fracturing technology. This technology first uses perforation in the wellbore. The gun performs cluster perforation on the formation to form fractures in the formation, and then the fracturing fluid containing proppant (sand-carrying fluid) and fracturing fluid without proppant (mid-top fluid) are pumped in pulses by the ground fracturing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): E21B43/267G06F17/50

Inventor 卢聪陈滔郭建春张涛陈迟

Owner SOUTHWEST PETROLEUM UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap