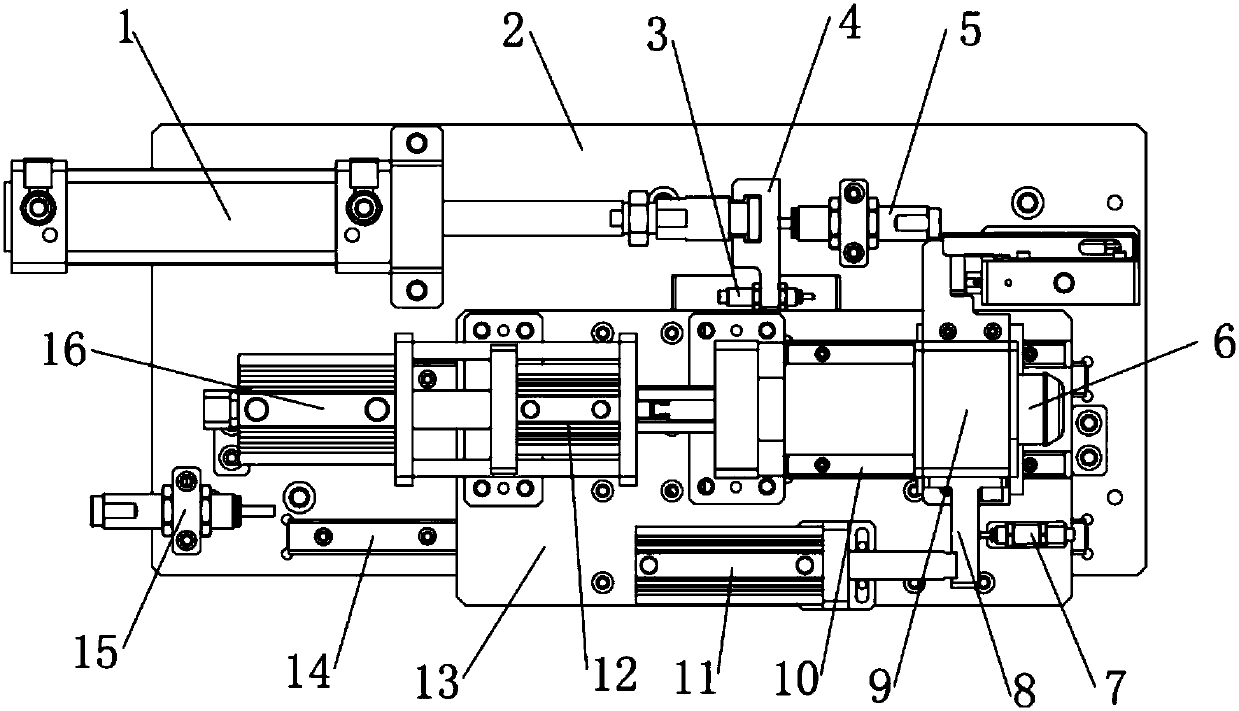

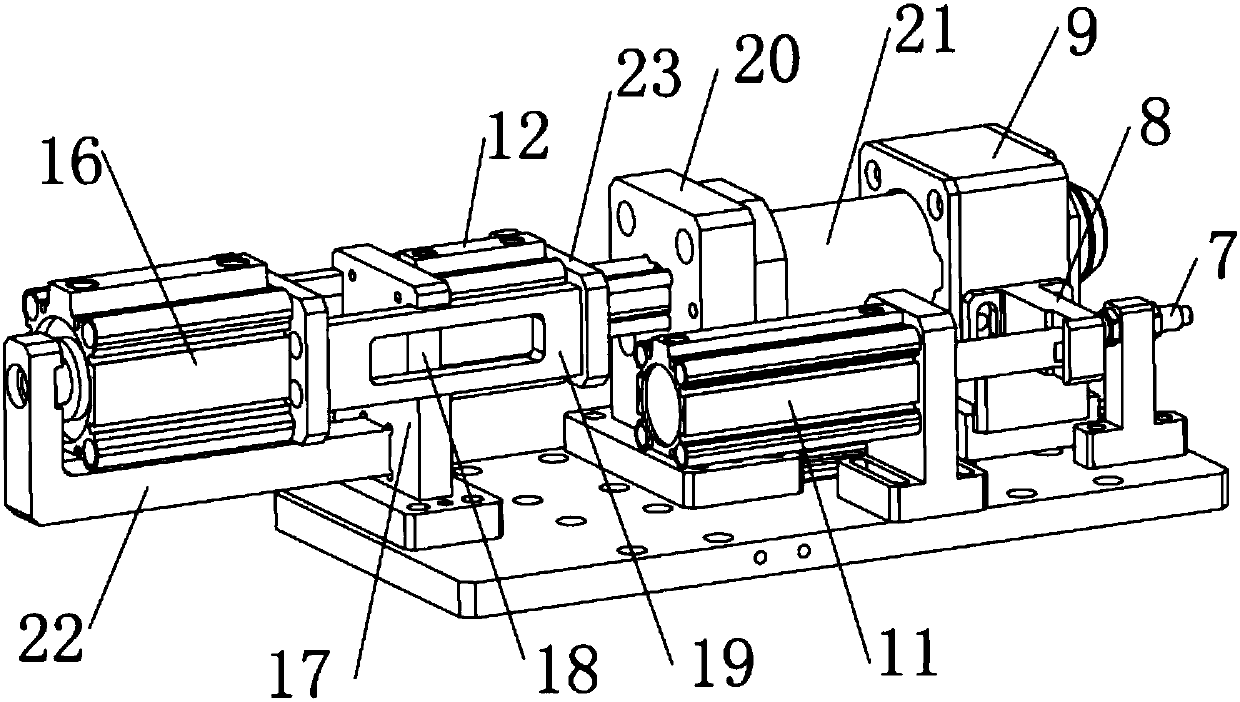

Continuous tensioning and positioning device applied to air inlet end of exhaust pipe

A technology of positioning device and air intake end, which is applied in the direction of measuring device, vehicle test, fluid tightness test, etc. It can solve the problems that affect the detection accuracy, the size is difficult to control, and the product positioning is unstable, so as to achieve stable positioning and Good sealing and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

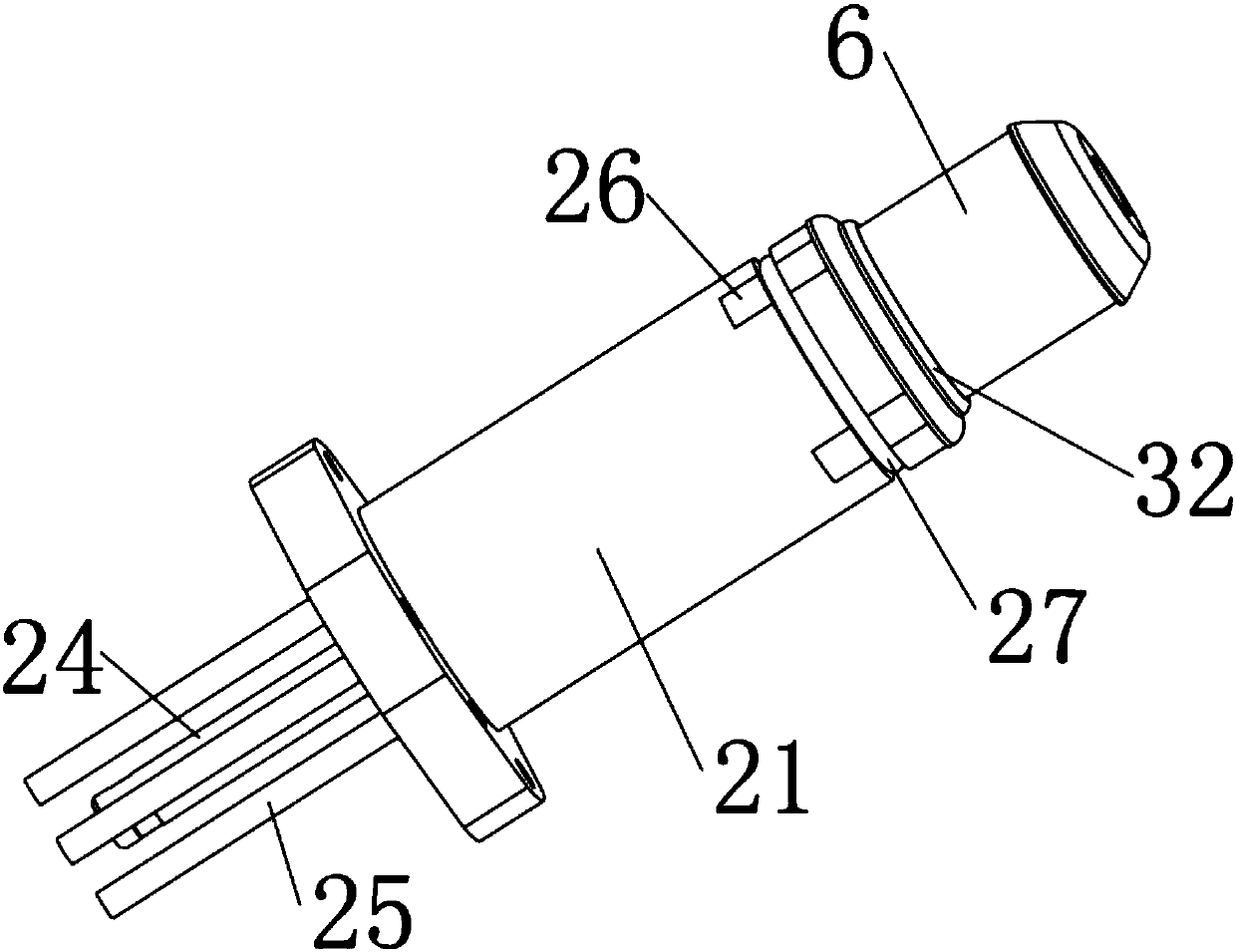

[0035]First, the extension of the piston rod of the first cylinder 1 drives the movable plate 13 to move to the right, and the bushing 21 and the plug 6 extend into the joint of the exhaust pipe. When the second connecting piece 4 touches the second sensor 5, it will move The plate 13 stops moving, and then the piston rod of the second cylinder 12 is extended to control the drive shaft 24 to move to the right, and the extrusion parts 28 on the drive shaft 24 also move to the right together. The reduced taper makes the extrusion part 28 continuously squeeze the positioning block 26, and the positioning block 26 moves along the positioning hole until the four positioning blocks 26 are closely attached to the inner hole wall of the exhaust pipe joint, realizing the exhaust The positioning and locking function of the inner hole of the pipe joint portion is to realize the internal positioning of the exhaust pipe, and at the same time, the drive shaft 24 drives the plug 6 to extend i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com