Plate-fuel-element power calibration method for fuel consumption measurement

A fuel element and calibration method technology, applied in the field of research reactor fuel irradiation, can solve the problems of difficult-to-test fuel element nuclear power and high share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

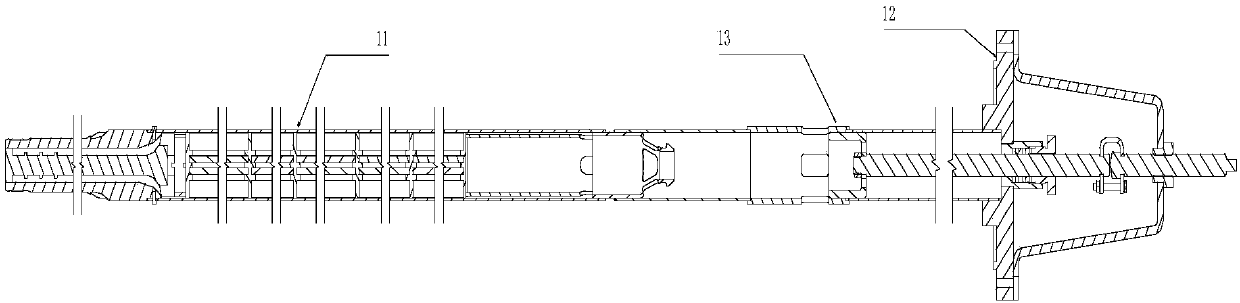

[0051] Such as figure 2 As shown, the hardware part of the plate-type fuel element irradiation test device involved in the present invention includes a device section 12 for connecting the research reactor pressure vessel shell and an external measurement system, etc., and is used for accommodating test fuel elements and connecting the device section 12 The test section 11 and the grid plate in the stack, and the device section 12 have the function of regulating the flow of coolant. The device section 12 is mainly composed of a bracket assembly, a flange assembly, a support pipe assembly, a water inlet pipe assembly, a flow adjustment assembly, and a thermocouple. The device segment 12 is also connected with the sealing mechanism of the core pressure vessel, the coolant inlet mechanism, the driving mechanism of the coolant flow regulating device, and the coolant flow regulating device.

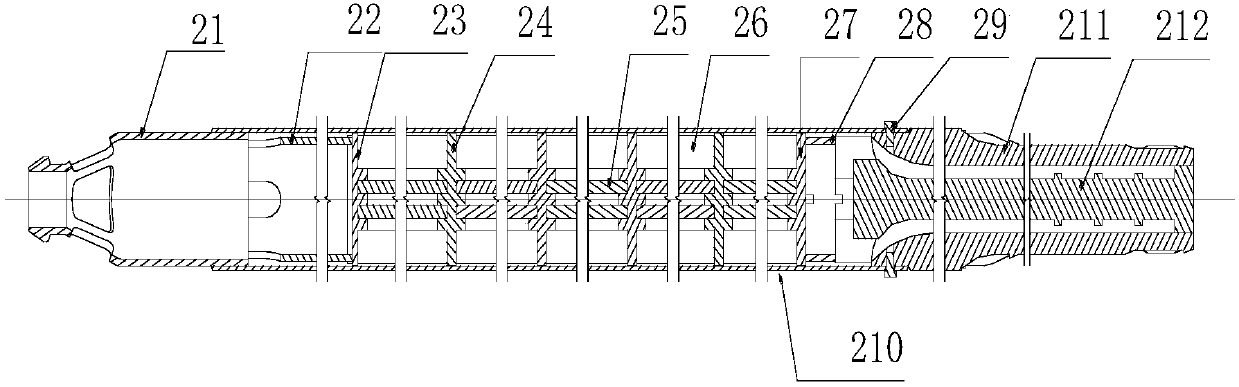

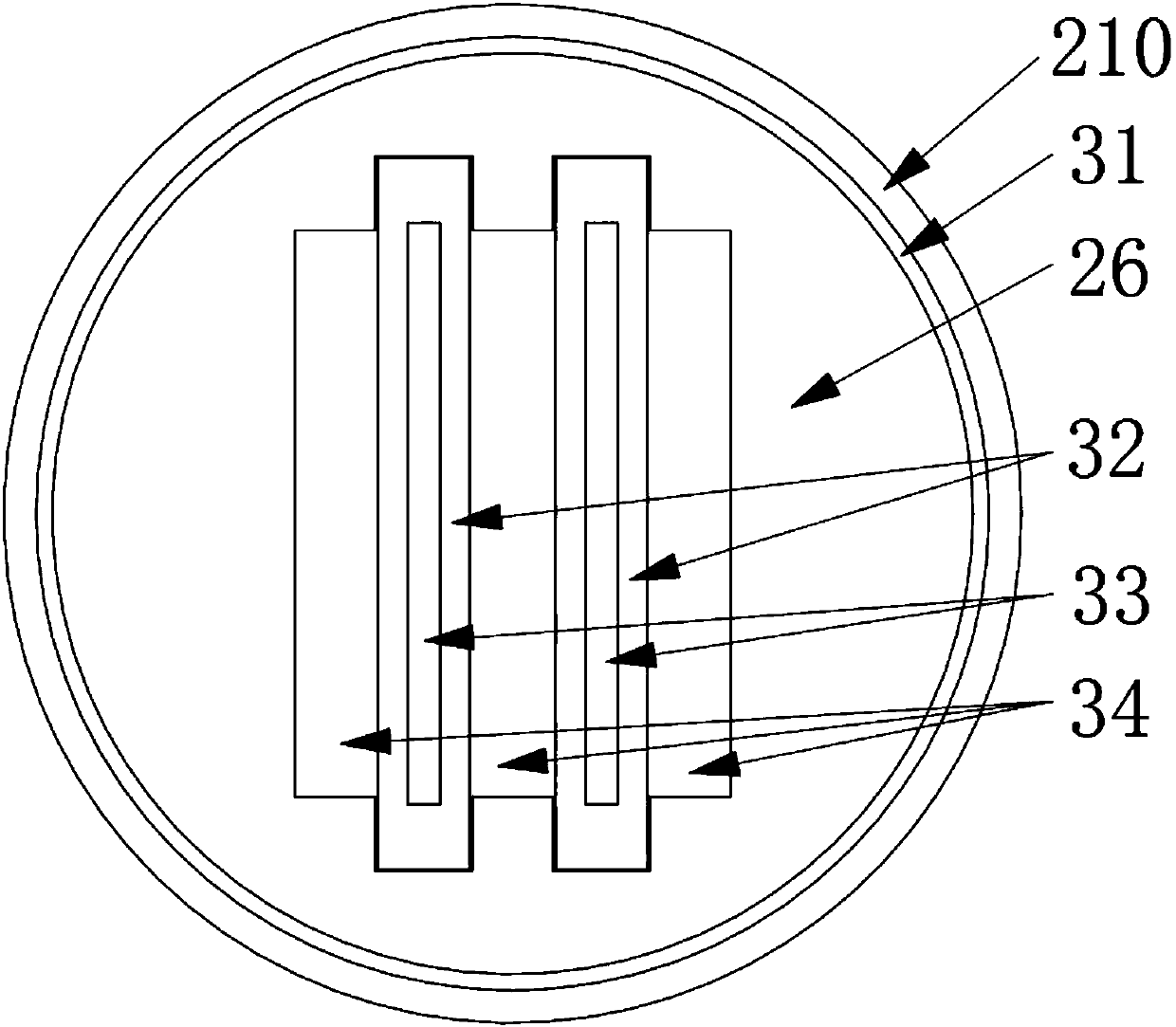

[0052] image 3 The mid-test section mainly consists of a combination plate composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com