Image detection method for automatically detecting straws left in grains

An automatic detection and image processing technology, applied in the field of image processing, can solve problems such as the need for near-infrared cameras, image processing result errors, and unsatisfactory processing conditions, so as to achieve convenient parameter adjustment, good operability, and reduce the impact of stacking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

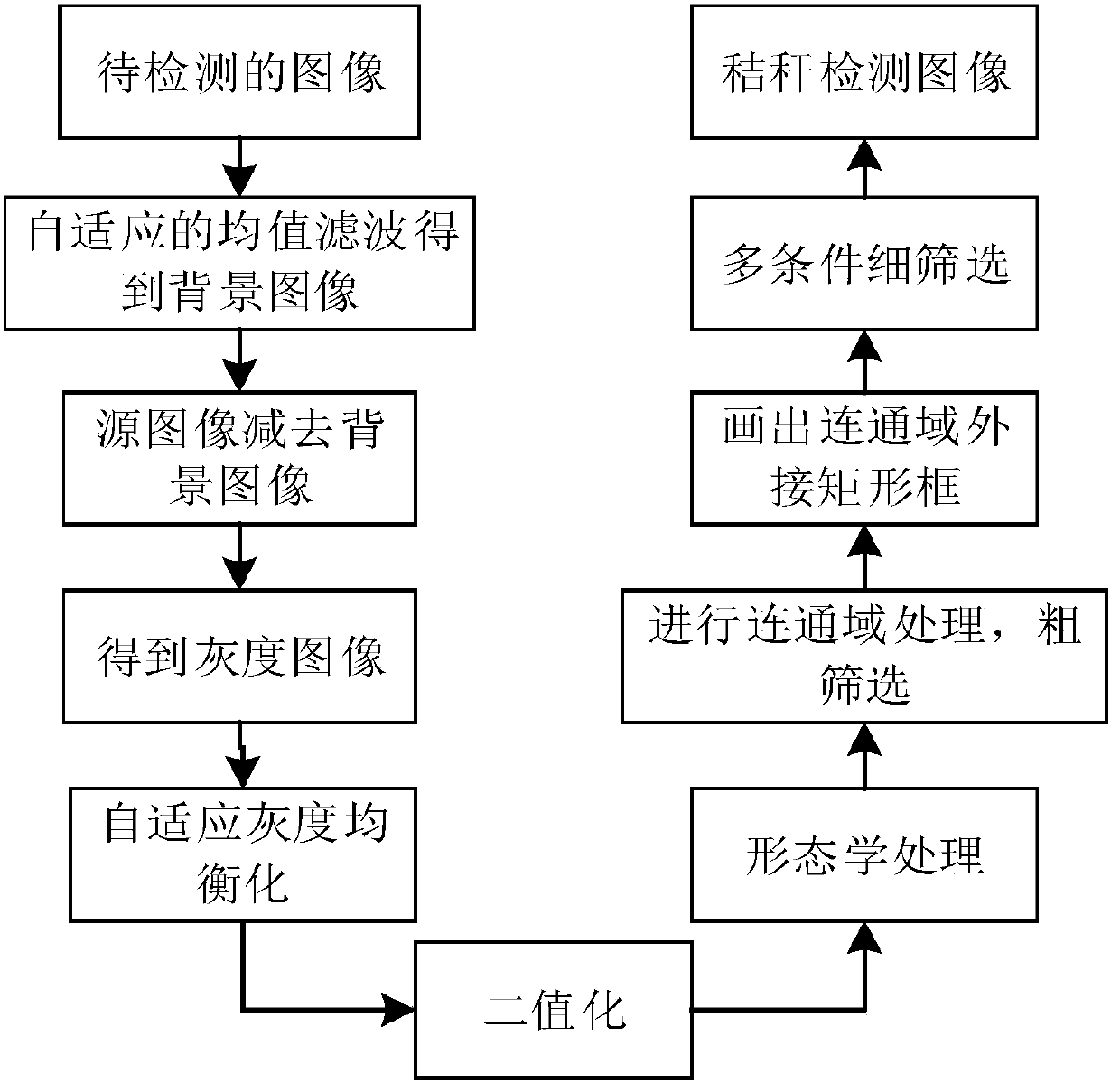

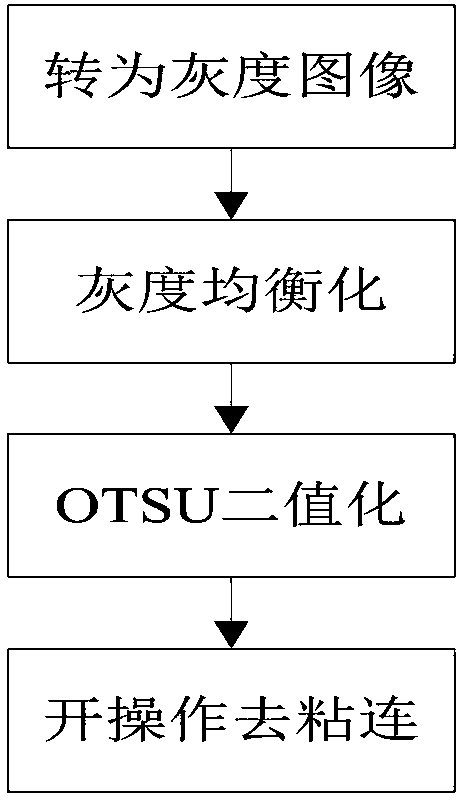

[0058] refer to Figure 1 to Figure 4 As shown, the image processing method for automatic detection of residual straw in grains includes the following steps:

[0059] Step 1: the camera collects the original image, and the computer reads the original image.

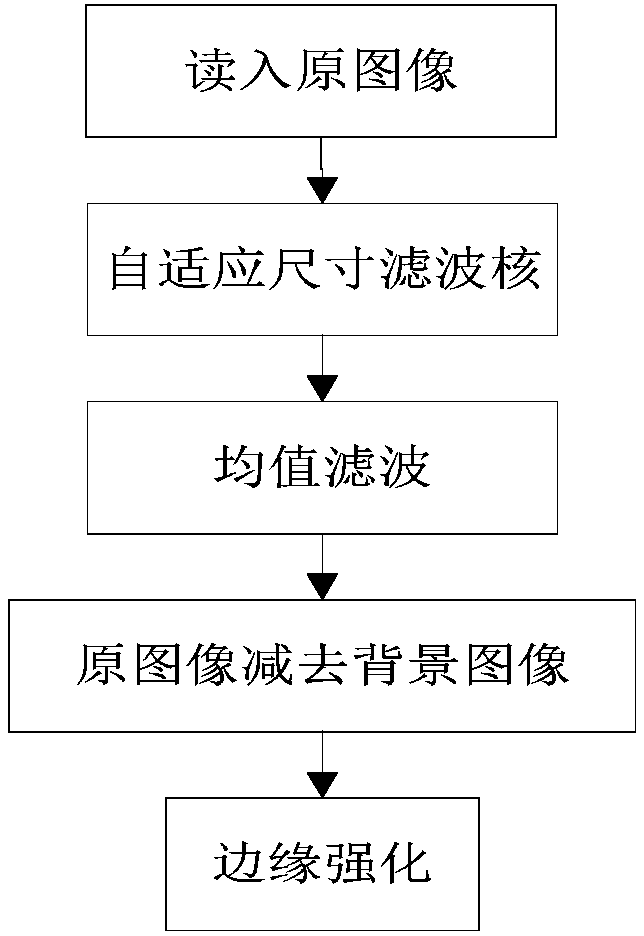

[0060] Step 2: If figure 2 As shown, the original image is subjected to adaptive mean filtering, the image is blurred, and the blurred image is used as the background image; and the background image is subtracted from the original image to obtain the edge-enhanced image after the edge of the foreground target is enhanced. Through this step of image preprocessing, the edges of each target can be better extracted, the influence of stacking can be reduced, and the stacking effect caused by direct contour detection can be avoided.

[0061] 2.1) Let the size of the original image be W×H, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com