Support disassembling device of steel pipe pile

A technology for steel pipe piles and steel plates, applied in the field of unloading devices for steel pipe pile supports, can solve the problems of unstable structure, uneven top surface of sand, stress concentration of upper components, etc., achieving no uneven stress, convenient operation, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

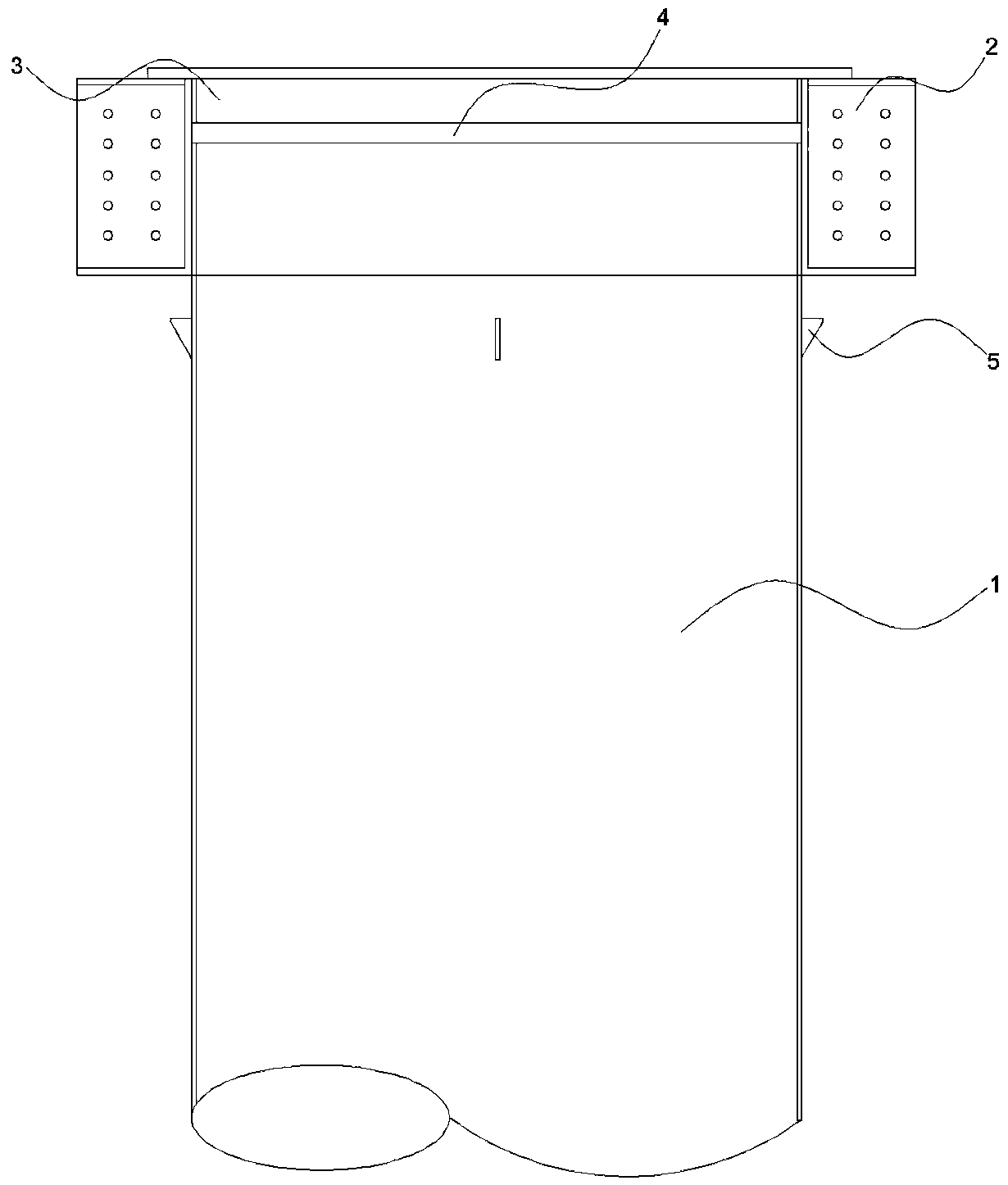

[0033] Such as figure 1 , figure 2 with image 3 A steel pipe pile support unloading device shown includes a steel pipe pile 1, a steel hoop 2 is arranged on the steel pipe pile 1, a column cap section 3 is arranged on the steel hoop 2, and the column cap section 3 is connected with the steel pipe There is an unloading stroke space 4 between the piles 1 . The steel pipe pile 1 is provided with a shelving ear 5 .

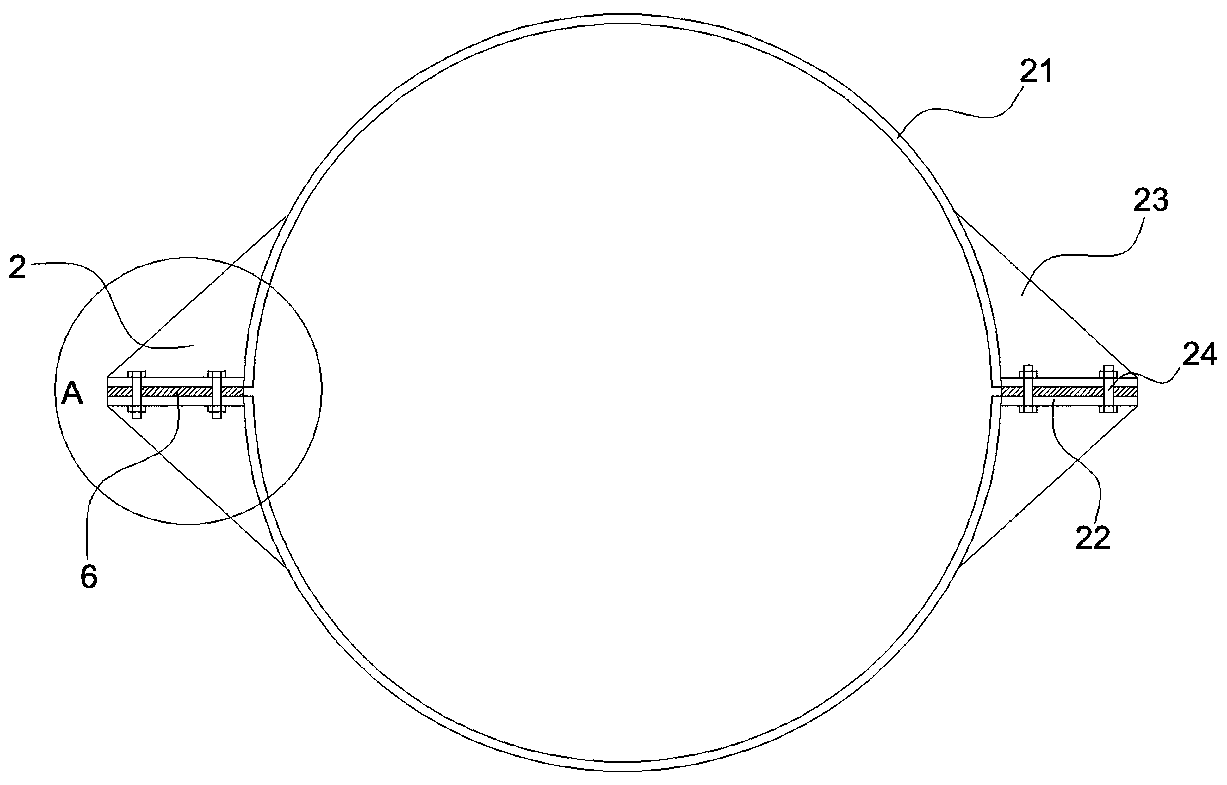

[0034] The steel hoop 2 includes two steel hoop bases 21, connecting plates 22 arranged at both ends of the steel hoop base 21, stiffeners 23 connecting the steel hoop base 21 and the connecting plate 22; The connecting plate 22 at the end of the hoop base 21 is connected by ten high-strength bolts 24 arranged in two rows in the vertical direction.

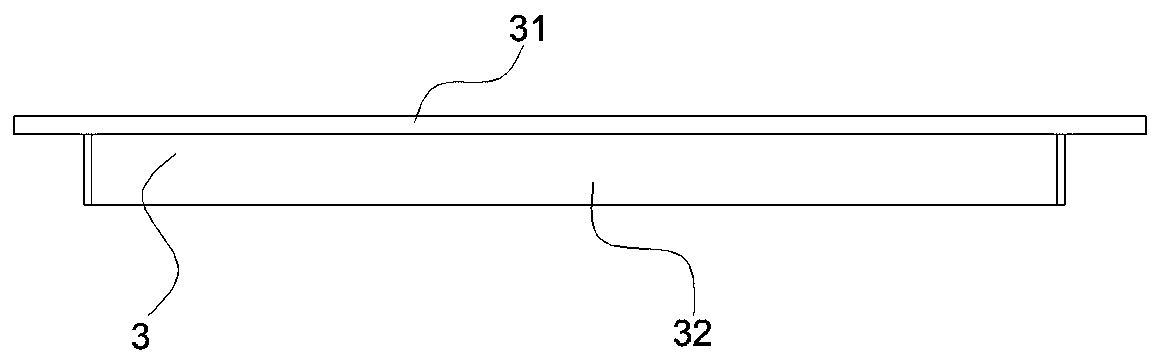

[0035] The column cap section 3 includes a column cap steel plate 31 and a nested column section 32 fixedly connected with the column cap steel plate 31 .

[0036] The above-mentioned steel hoop 2, column cap secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com