A method of making a multi-cavity etalon

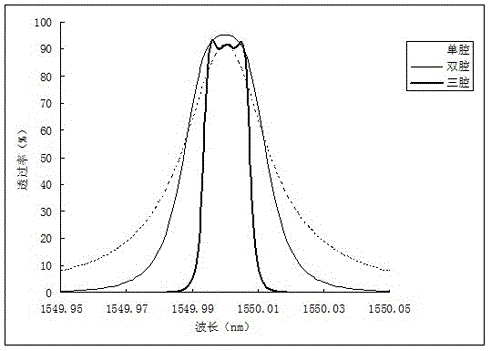

A production method and etalon technology, applied in the field of optics, can solve problems such as difficulties in production schemes, achieve the effects of large steepness, wide passband bandwidth, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

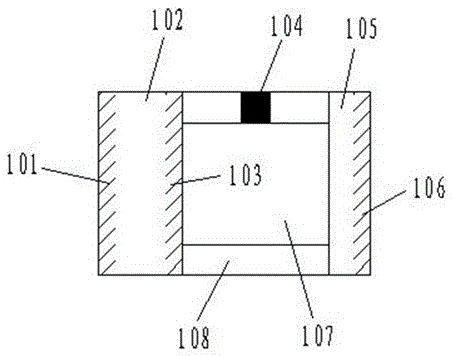

[0021] Such as figure 1 As shown, the double-cavity etalon includes a solid cavity 102 and an air cavity 107. 101, 103, and 106 are reflective films with certain reflectivity. 105 is a fused silica flat sheet, 108 is a spacer block, and 104 is an air-filled hole. In the process of processing, cold working is adopted, and the spacer block 108 is roughly processed to the designed thickness and then glued together with the solid cavity 102 with light glue or deepened light glue, and the fused quartz flat plate 105 is glued with the spacer block 108 with light glue or deepened light glue, A double-chamber etalon is formed. Then test the transmission peak of the double-chamber etalon. If the measured transmission peak deviates from the design value, then inject a certain pressure of nitrogen into the air chamber 107 through the air hole 104 to make the transmission peak of the double-chamber etalon consistent with the design value. , and finally the air hole is sealed to complete...

Embodiment 2

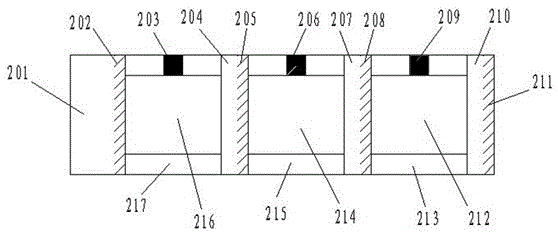

[0024] Such as figure 2 As shown, the three-chamber etalon includes a first air cavity 216 , a second air cavity 214 and a third air cavity 212 . Wherein 201, 204, 207, 210 are fused quartz flat plates, 213, 215, 217 are spacer blocks, 202, 205, 208, 211 are reflective films with a certain reflectivity, and 203, 206, 209 are air-filled holes respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com