A Simulation Method of General Numerical Simulation Box for 3D Discrete Element Rapid Modeling of Rock and Soil Mass

A simulation method and numerical simulation technology, applied in electrical digital data processing, design optimization/simulation, instruments, etc., can solve problems such as complex operation, large amount of calculation, low efficiency, etc., and achieve efficient modeling method and reduce the amount of calculation , the effect of efficient modeling and simulation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

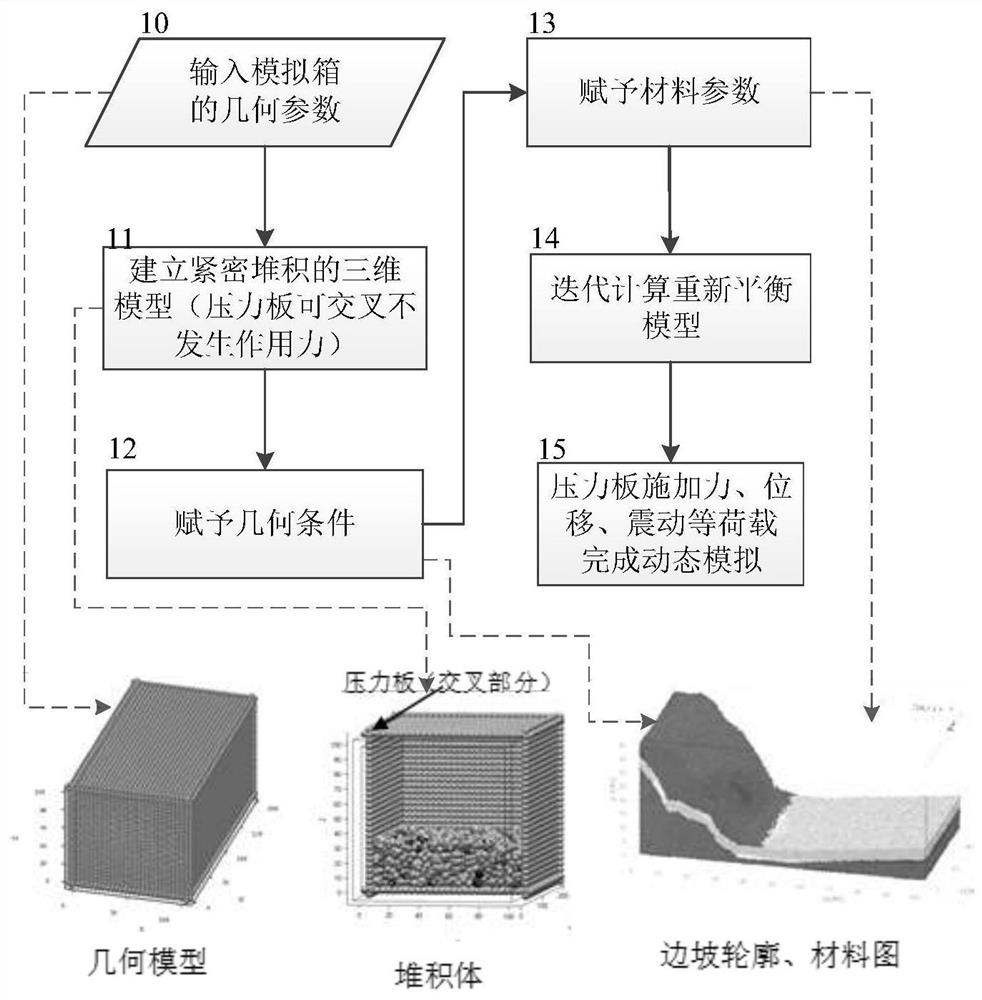

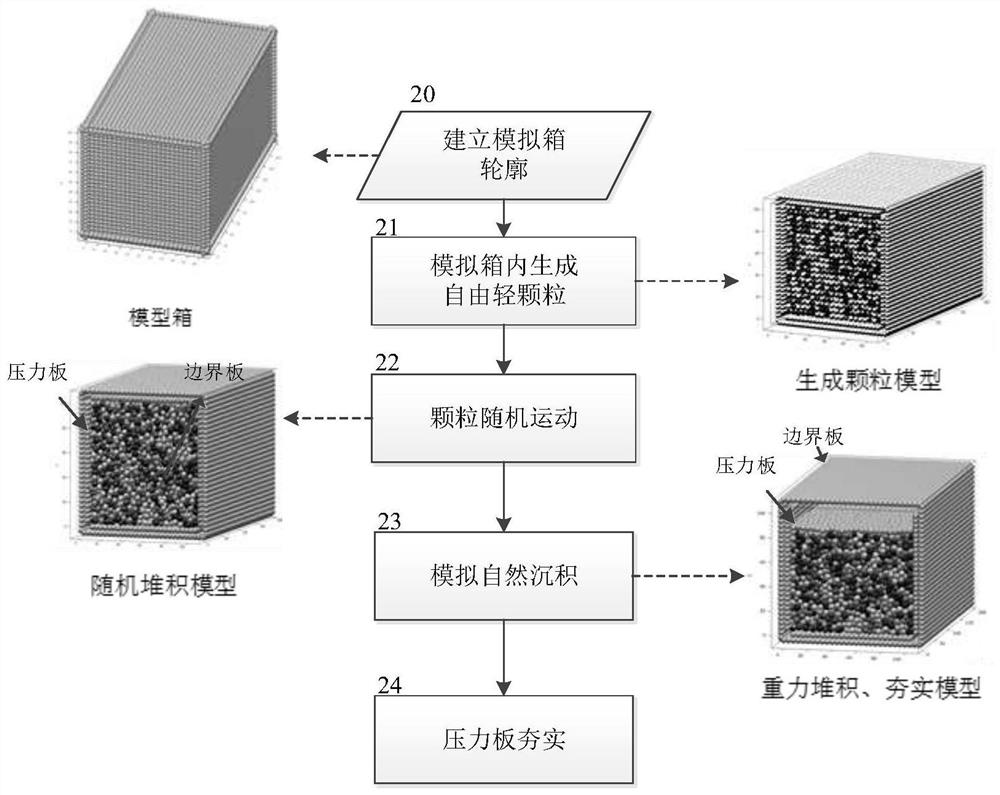

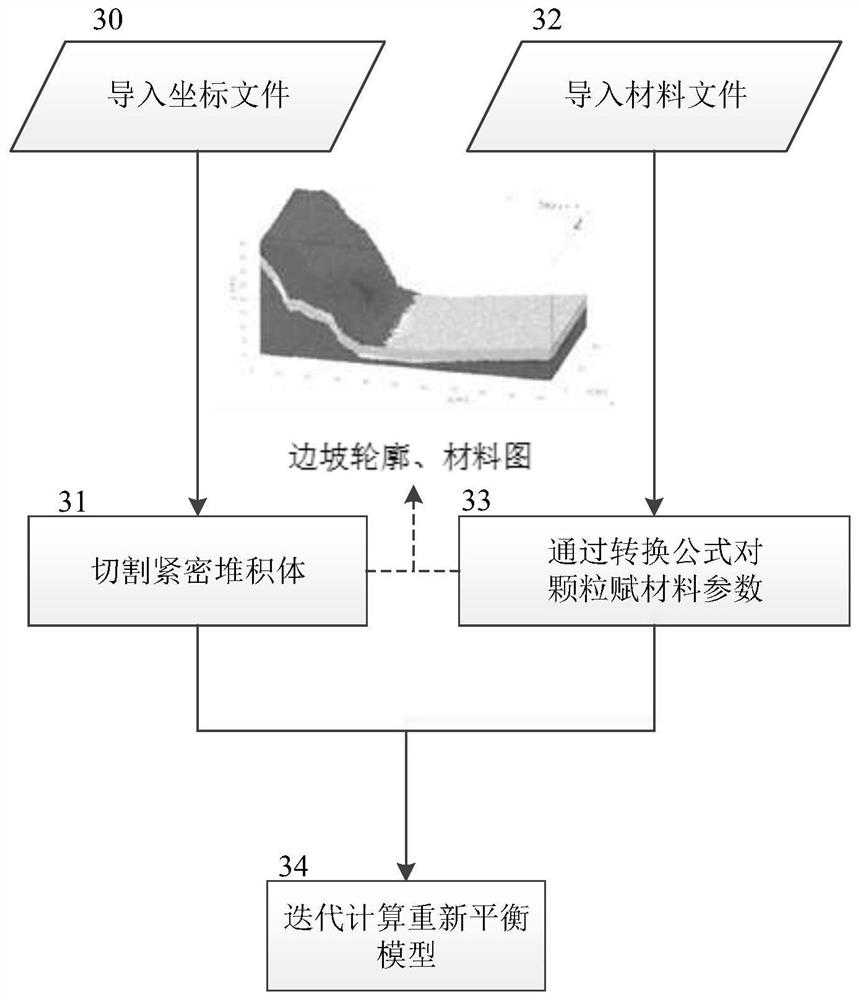

[0010] The working process of the inventive method is as Figure 1-Figure 4 shown.

[0011] figure 1 Flowchart of the implementation of the generic simulation box modeling and simulation method for 3D discrete element models.

[0012] Step 10 Input the geometric parameters of the three-dimensional simulation box to establish the outer contour of the simulation box, including the outer boundary plate and the inner boundary pressure plate. Both plates are composed of spherical particles with a particle size similar to that of the sample, and the boundary plate is rigid. , to apply boundary displacement, and the pressure plate is flexible to buffer boundary displacement and generate pressure.

[0013] Step 11 creates a close-packed body. Close-packed heaps are created by gravity deposition and cyclic compaction.

[0014] Step 12 assigns geometric conditions. According to the geometric shape and layered boundary conditions of the structure, the external coordinate file is rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com