Method of determining different stock line (Sl) compensation angles in blast furnace burden distribution process

A technology for compensating angles and material lines, applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as large randomness, lack of test and theoretical basis for accuracy, and improve accuracy, improve drop point accuracy, and reduce deviation moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

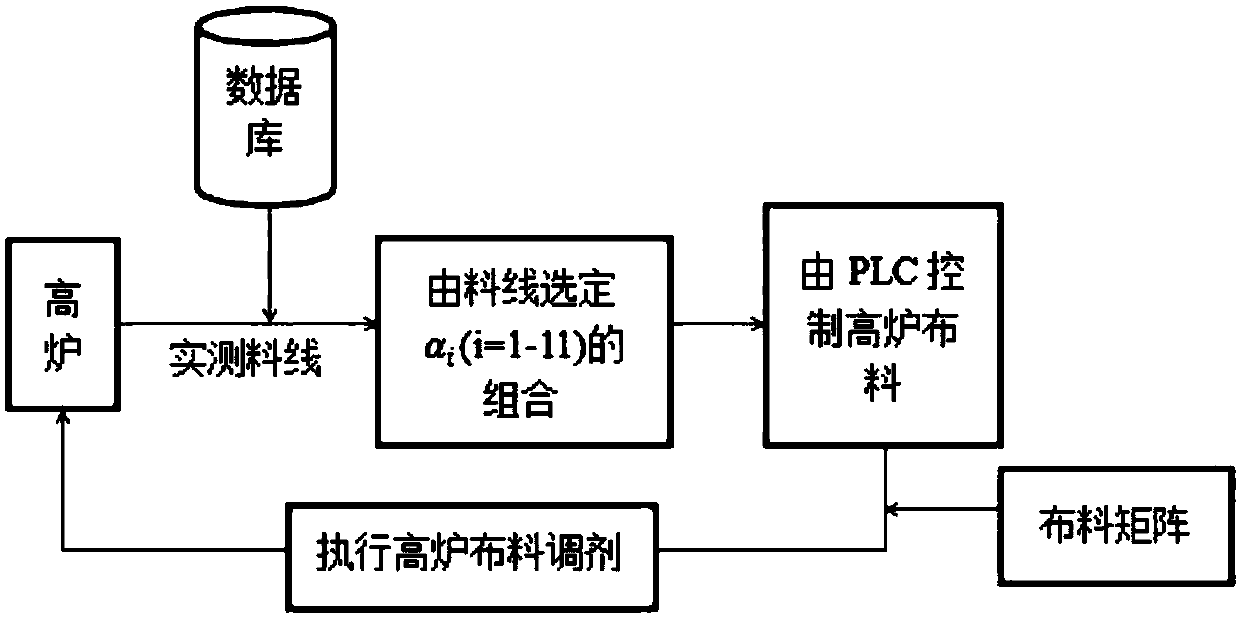

[0047] Embodiments of the present invention are described in detail with reference to the accompanying drawings.

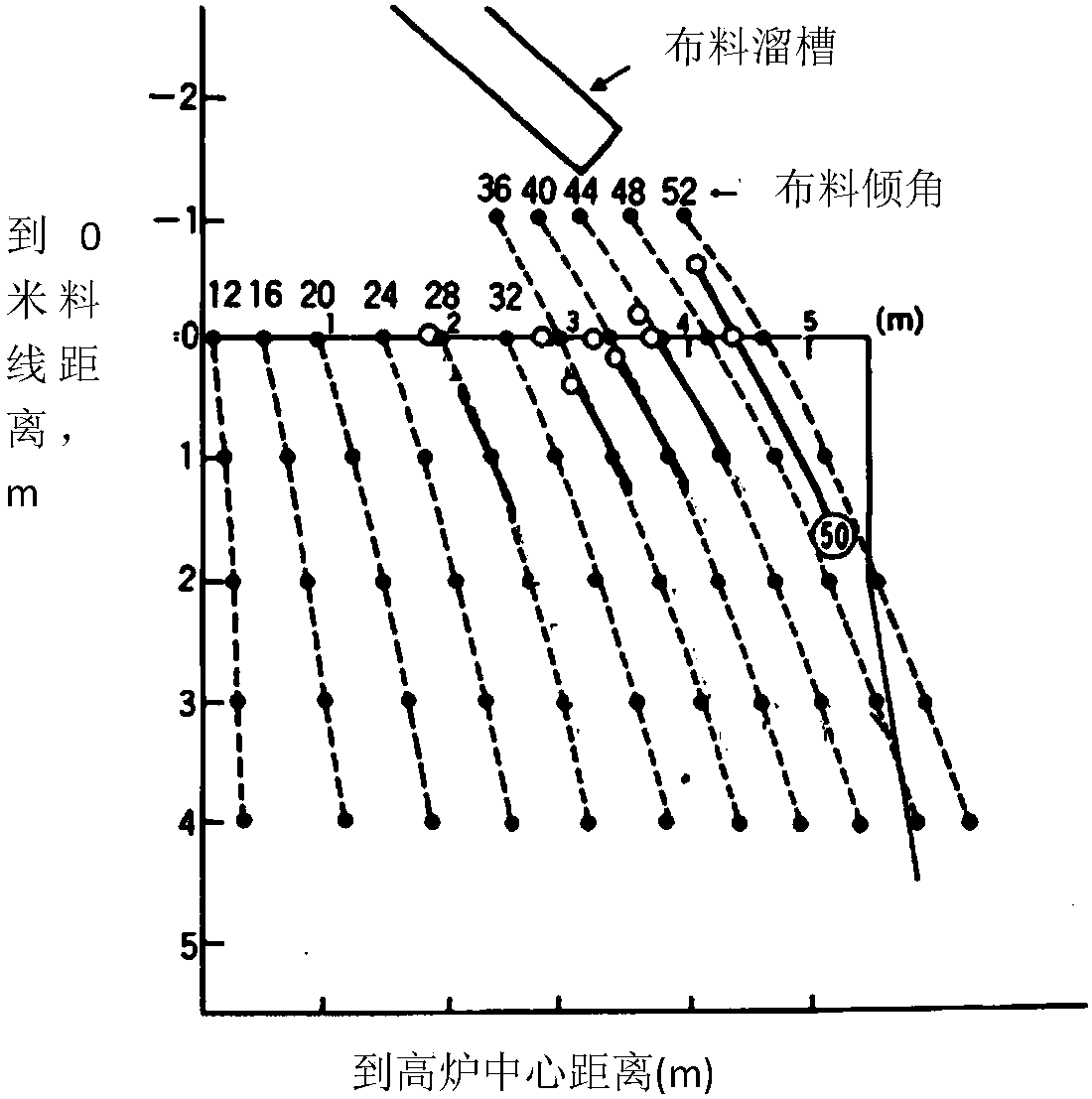

[0048] Take a 3400m 3 Take the blast furnace as an example. The blast furnace is equipped with a bellless distribution device. The length of the chute is 3.8 meters and the diameter of the chute is 750mm. Taking the distribution of coke as an example, there are 11 distribution corners in total. When the chute is placed at 11 corners, the material flow trajectory is as follows: figure 1 shown.

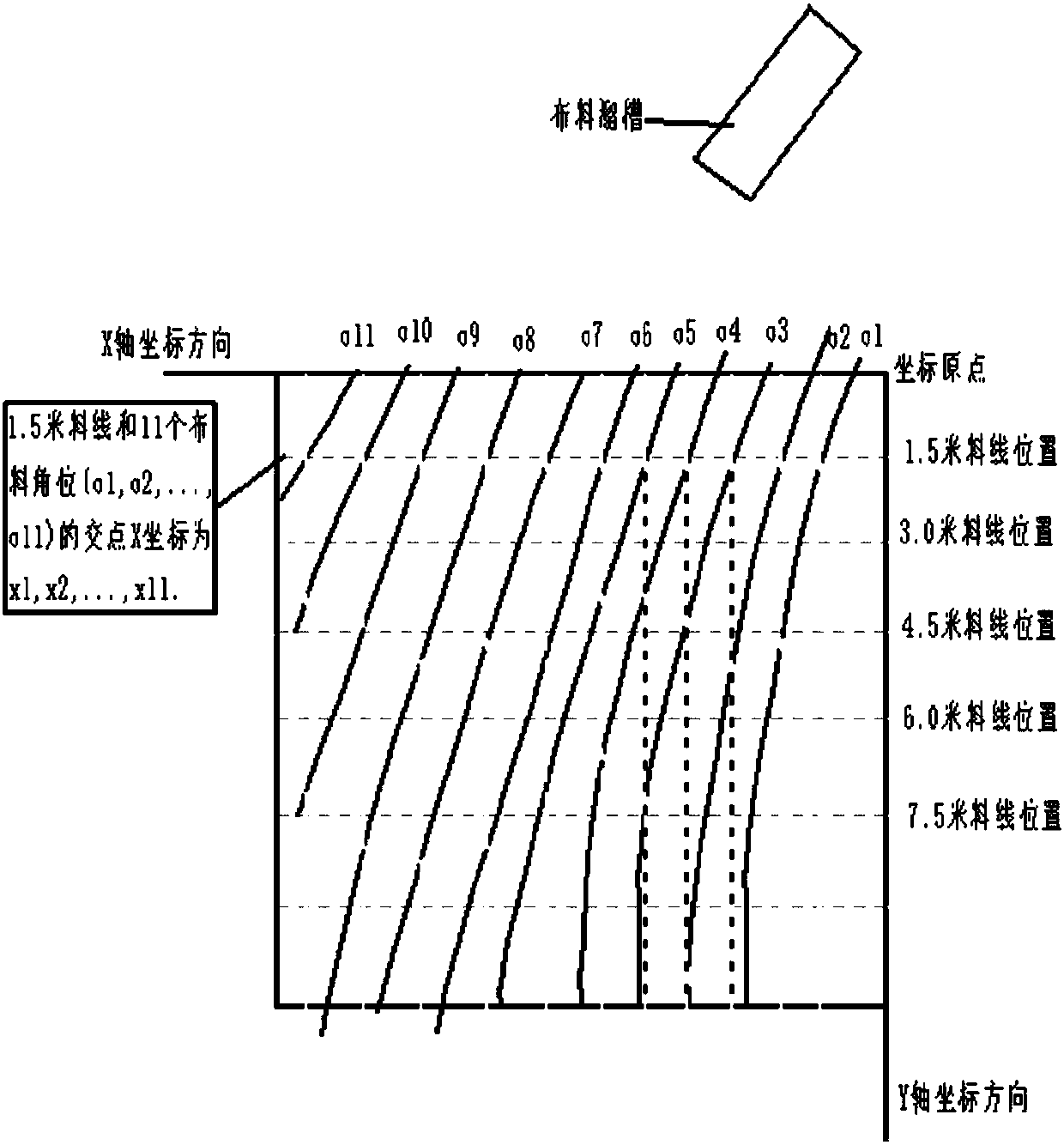

[0049] Step 1) The coordinate solution unit of the intersection point coordinates of each chute's corner charging charge trajectory and the reference material line:

[0050] As shown in Table 1, the trajectory drop points of the actual measured material distribution trajectory on the material line of 0, 1, 2, and 3 meters are shown in Table 2 when the furnace is turned on.

[0051] Table 1 11 fabric corner positions

[0052]

1

2

3

4

5

6

7 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap