Fully-automatic watering spray gun

A fully automatic, spray gun technology, applied in the field of sanitation, can solve the problems of heatstroke and cold among sprinklers, and achieve the effect of easy long-distance operation, avoidance of tacit understanding, and wide spraying area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

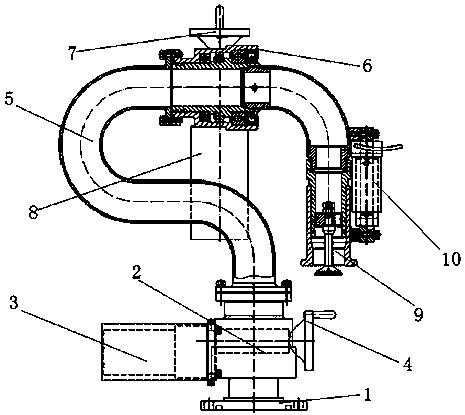

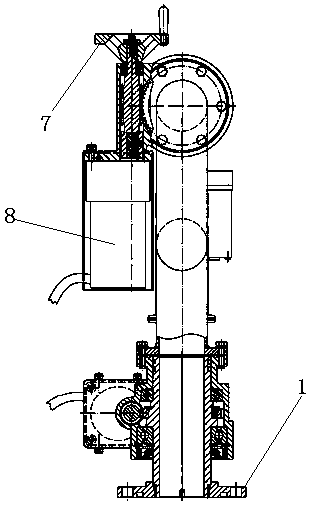

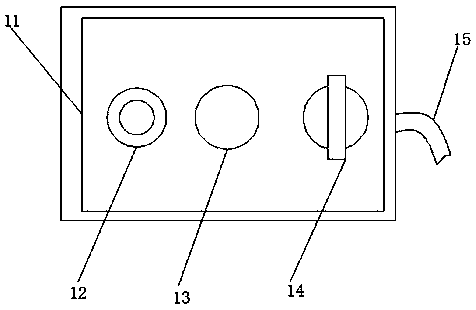

[0022] A fully automatic sprinkler gun, comprising a base fixing flange 1, the top of the base fixing flange 1 is provided with a left and right rotation mechanism 2, one side of the left and right rotation mechanism 2 is connected with a left and right rotation motor driving device 3, and the left and right rotation The top of the mechanism 2 is connected with an S-shaped connecting pipe 5, the top of the S-shaped connecting pipe 5 is provided with an up and down rotation mechanism 6, and the top of the up and down rotation mechanism 6 is provided with a second manual rotation device 7, and the up and down rotation mechanism 6 is one Side is connected with up and down rotation motor driving device 8, and described up and down rotation mechanism 6 one side is provided with telescopic spray gun head 9 that is communicated with S-shaped connecting pipe 5 through pipeline, and pipeline side is provided with electric push rod 10, and electric push rod 10 is connected to the retract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com