Hydraulic time difference braking device

A hydraulic braking technology, applied to bicycle accessories, bicycle brakes, etc., can solve the problems of starting braking, crash accidents, errors, etc., and achieve the effect of increasing braking force, improving braking efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

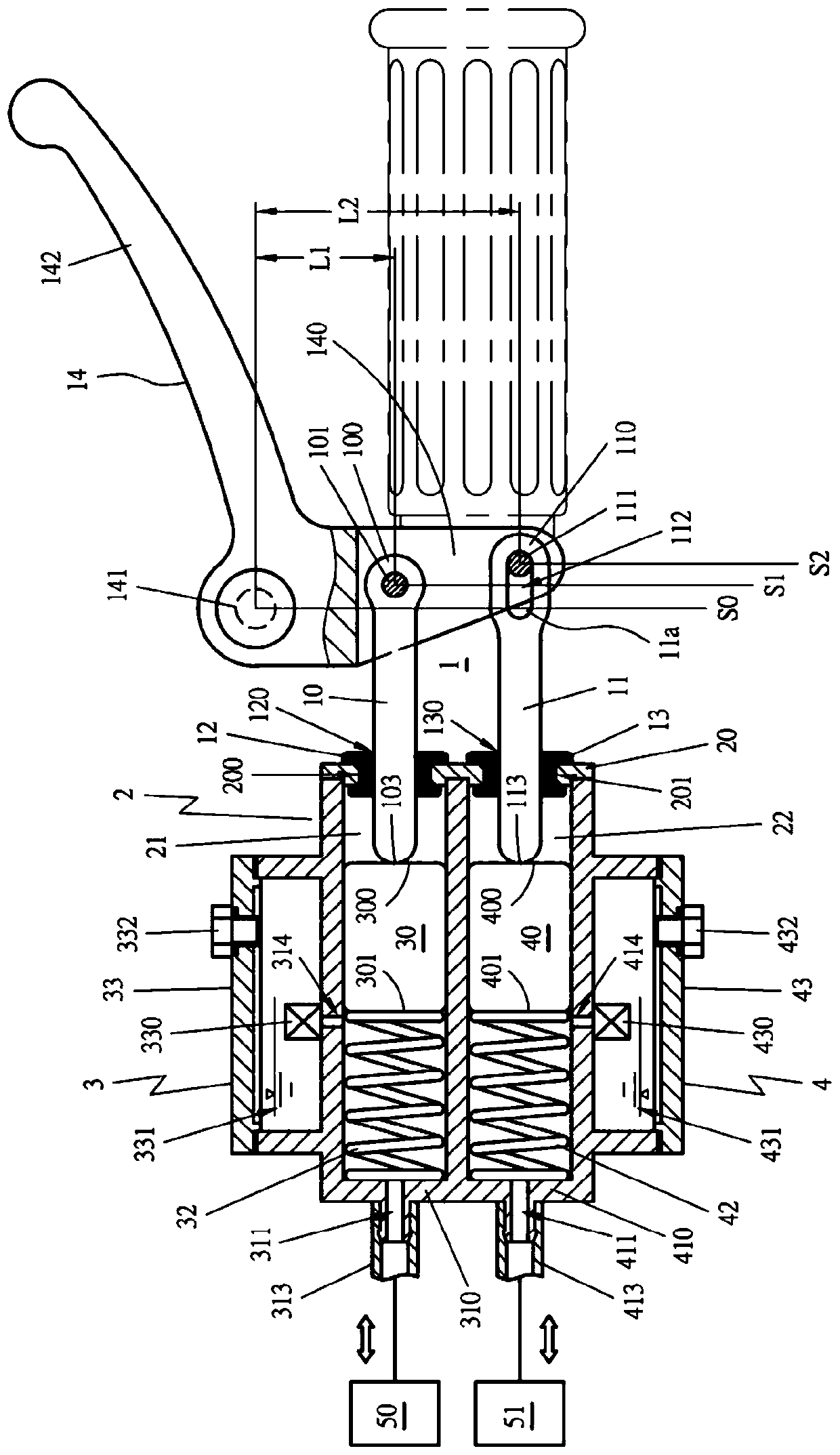

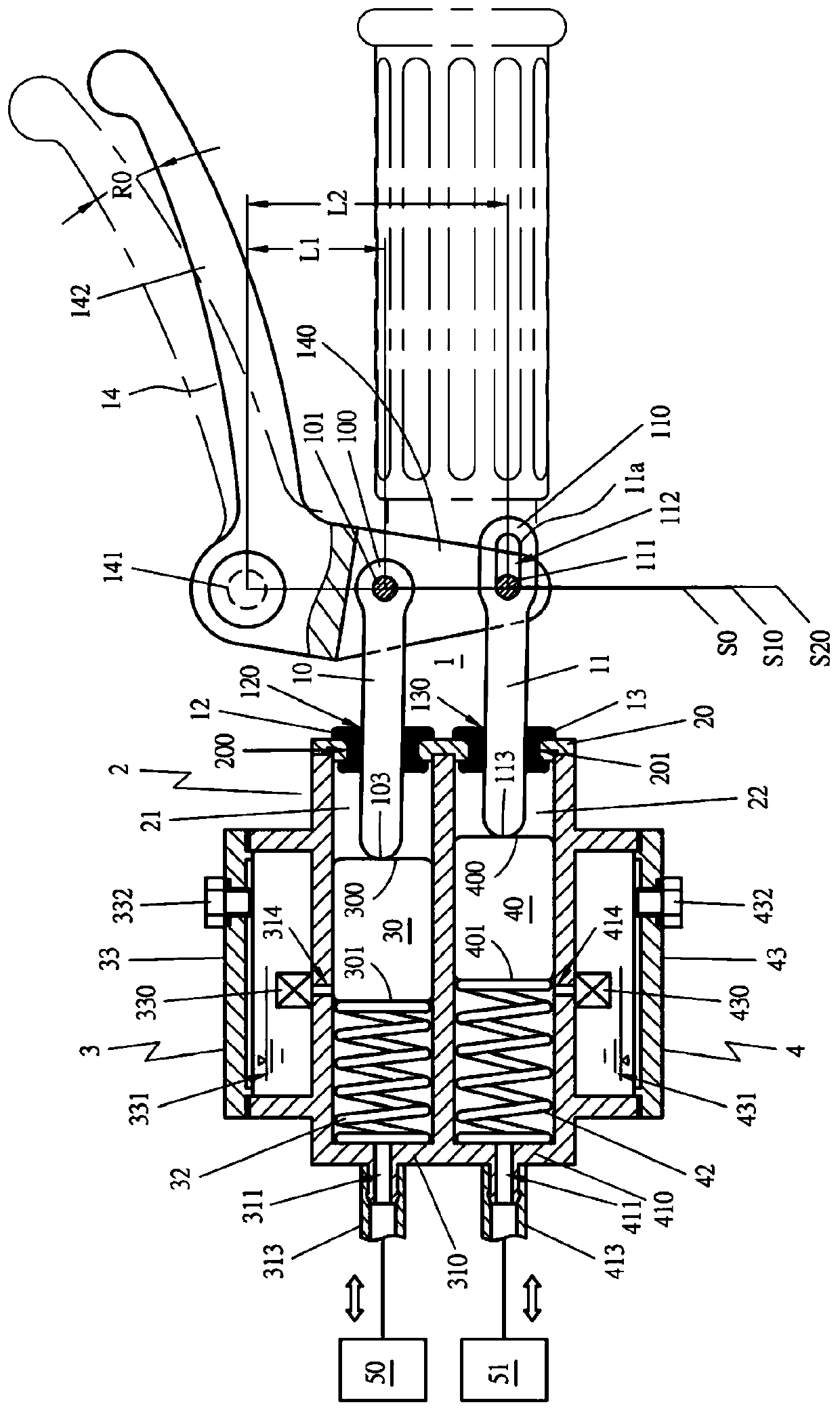

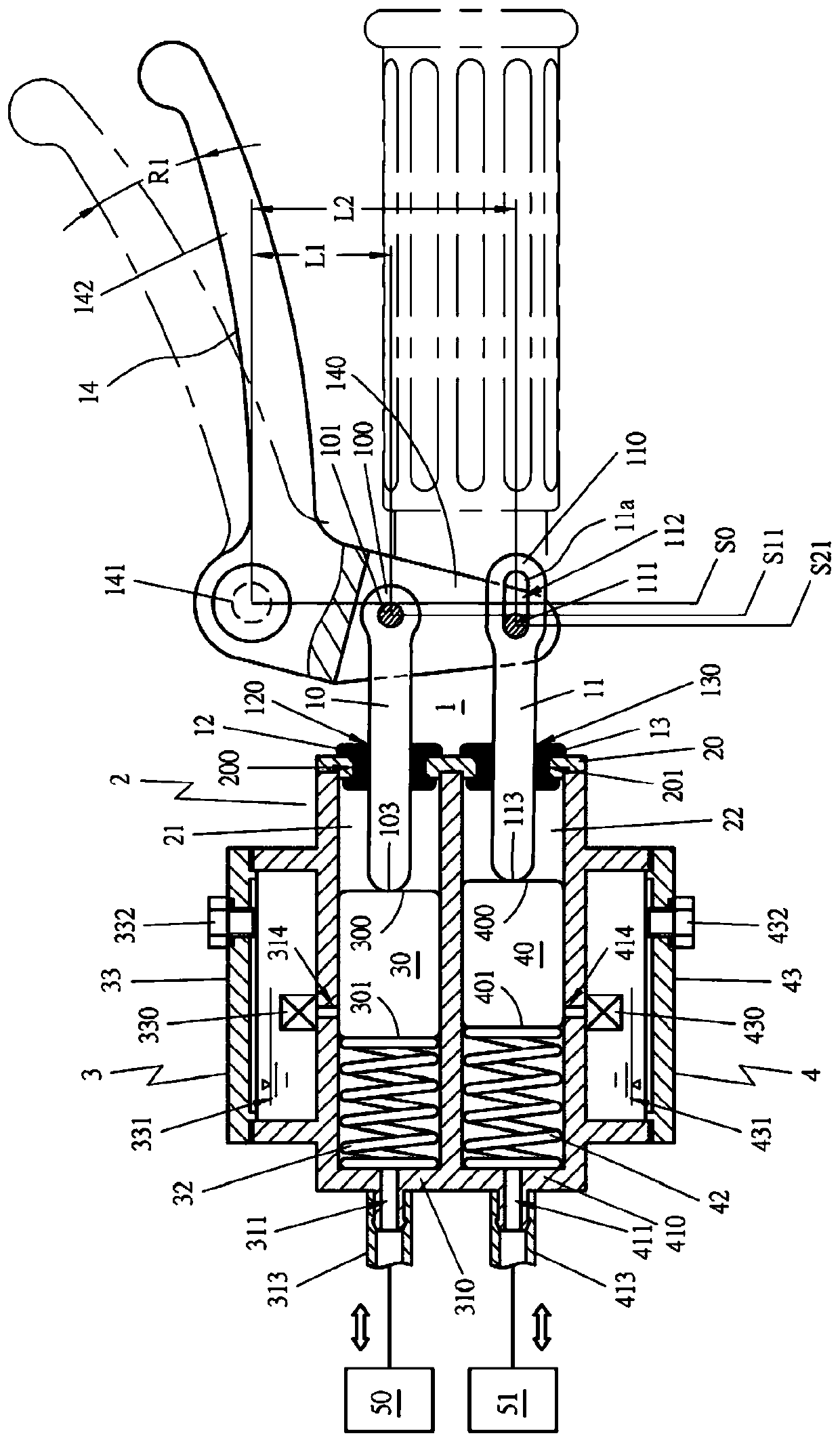

[0062] In order to allow the public to further understand the hydraulic time difference braking device described in the present invention, the best implementation mode is explained as follows with reference to the accompanying drawings:

[0063] like Figure 1-4 As shown, the hydraulic time difference braking device of the present invention at least includes: a driving mechanism 1, a first driving rod 10, a second driving rod 11 and a brake driving element 14, the outer end 100 of the first driving rod 10 The supporting shaft 101 passes through, and is combined with the driving part 140 of the brake drive element 14 through the supporting shaft 101. The aforementioned first driving rod 10 and the supporting shaft 101 are movable structures. In this state, the first driving rod 10 is driven by the brake driving element 14 to freely displace along a certain track. The first driving rod 10 passes through the middle hole 120 of the first rod seat 12 with appropriate flexibility, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com