Insulating base insert clamping device and insulating base insert processing method

A technology of clamping device and insulating seat, which is applied in the direction of clamping device, positioning device, metal processing equipment, etc., and can solve the problem of repeated positioning error of insulating seat inserts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 5

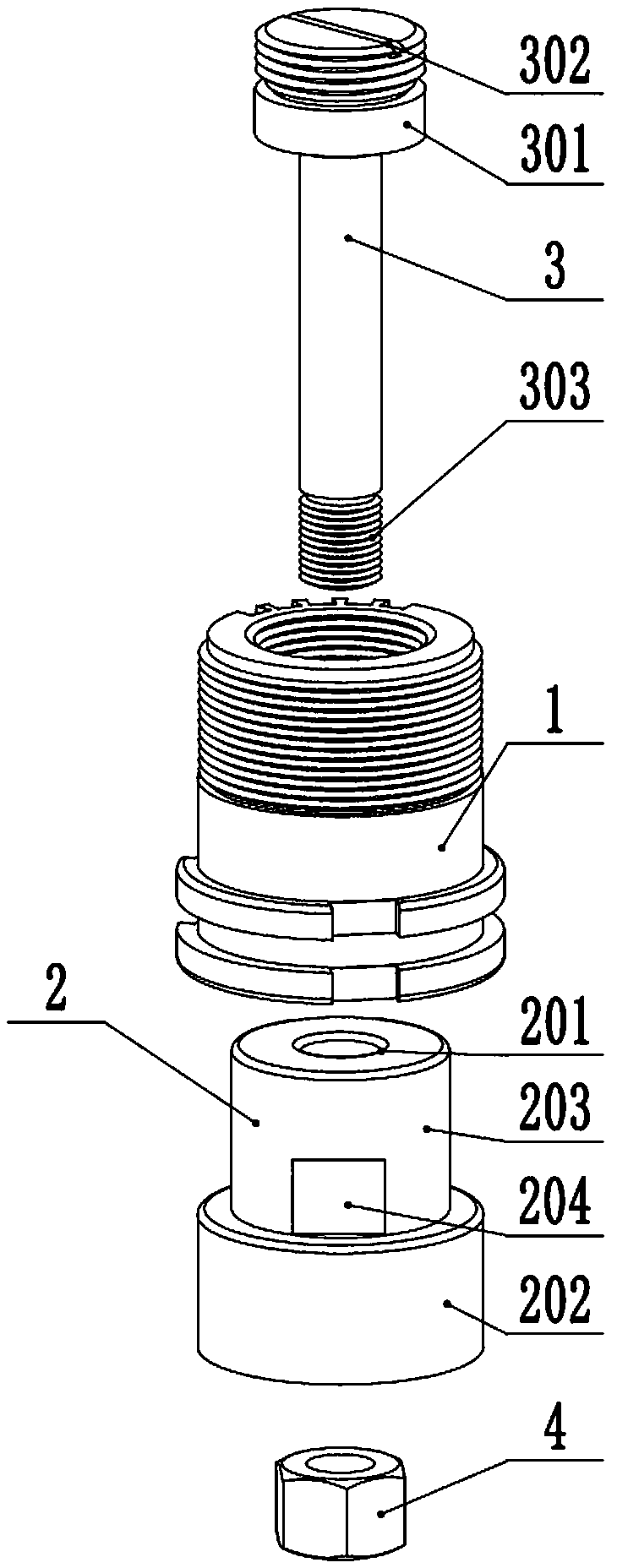

[0034] The specific embodiment 5 of the insulating seat insert clamping device of the present invention differs from the specific embodiment 1 of the insulating seat insert clamping device of the present invention only in that: Figure 8 As shown, the matching section between the connecting rod 53 and the perforation 5201 of the positioning seat 52 is conical, and the perforation 5201 of the positioning seat 52 is a conical hole for positioning and matching with the conical section of the connecting rod 53, and the connecting rod 53 and the insulating seat insert The small-diameter section of the inner hole is circumferentially positioned and matched.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com