Manufacturing method and manufacturing device for multi-layer acrylic plate

A manufacturing method and acrylic technology, applied in other home appliances, home appliances, applications, etc., can solve the problem of inability to make multi-layer acrylic panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

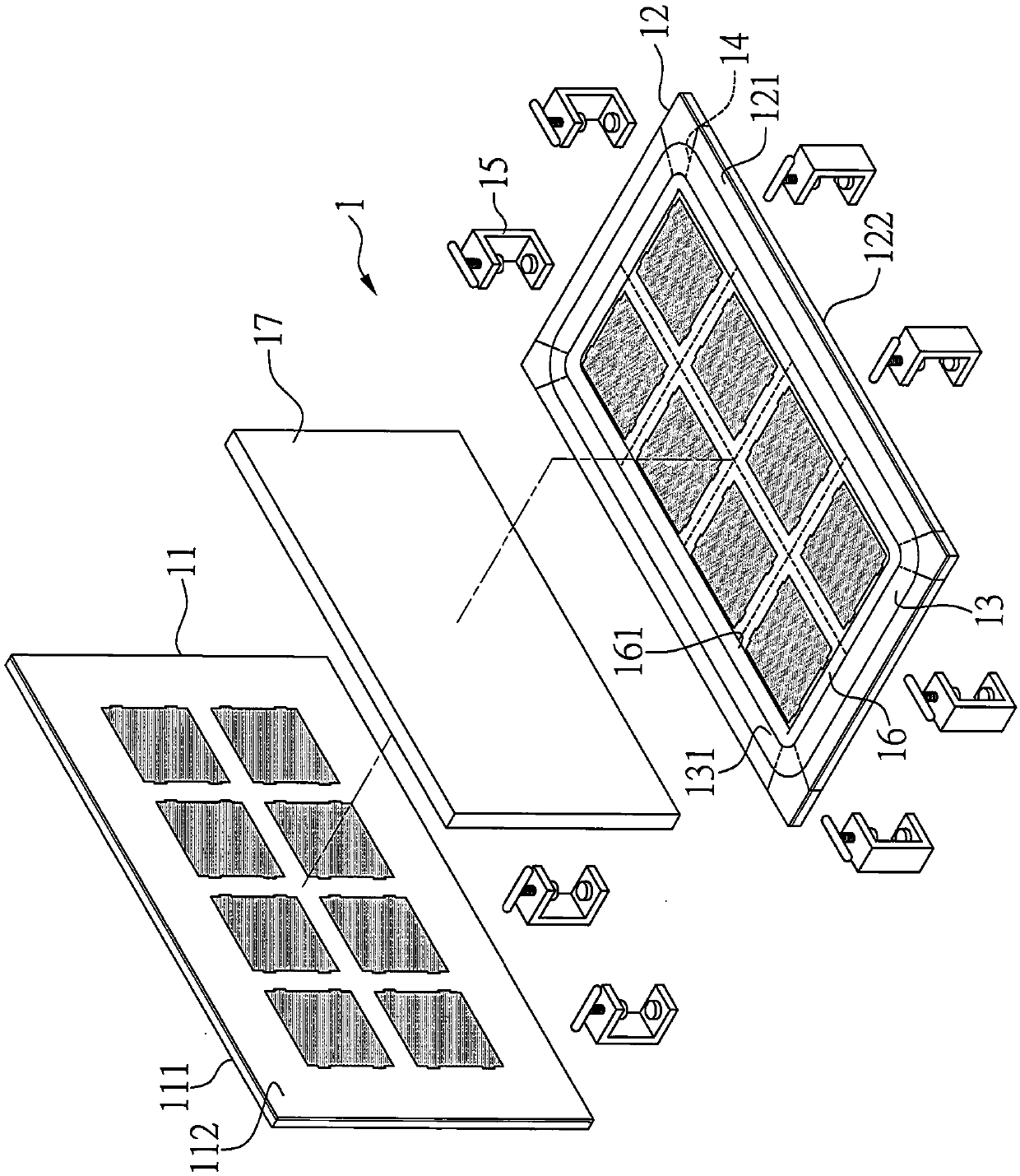

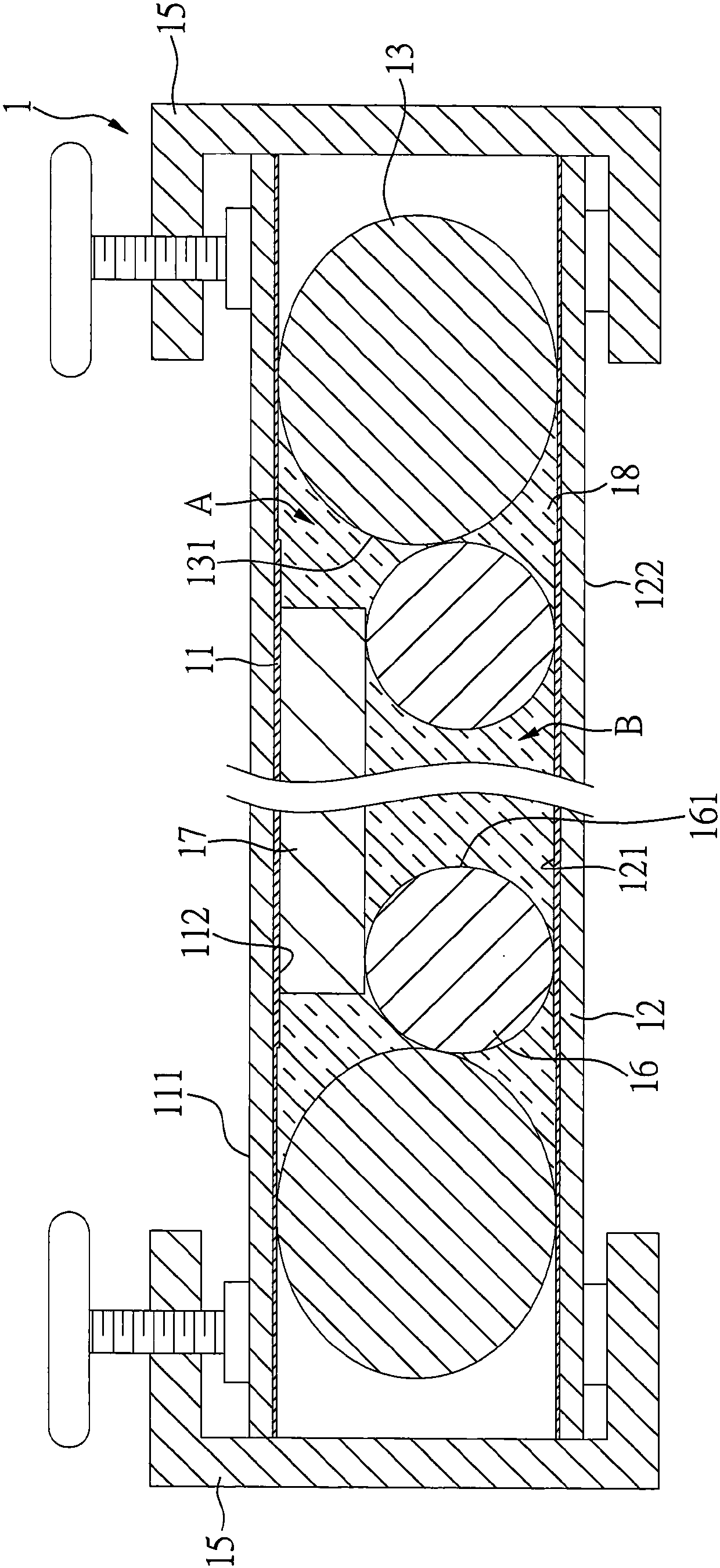

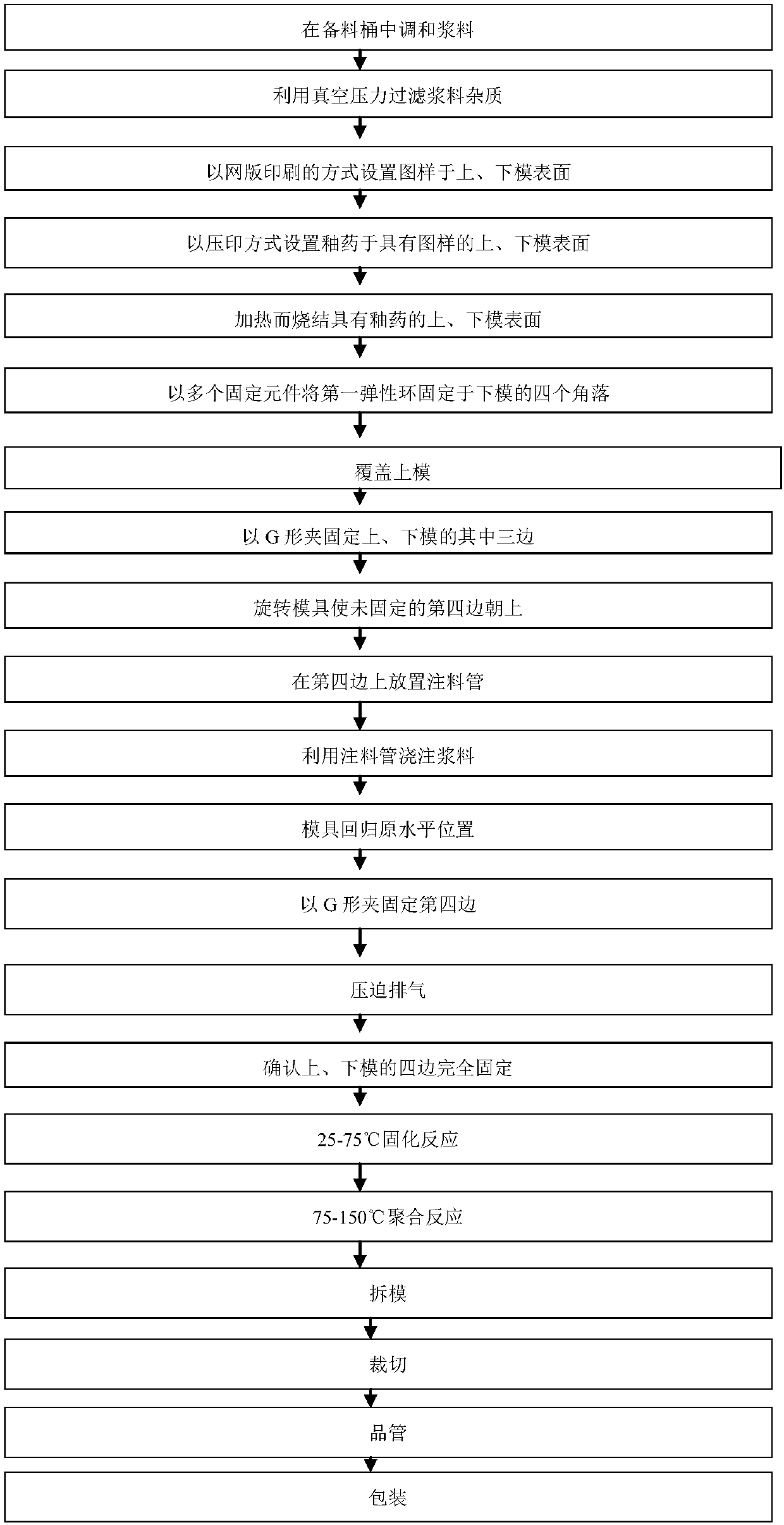

[0044] see Figure 1 to Figure 6 , shown in the figure is the structure of the selected embodiment of the present invention, which is for illustration only, and is not limited by this structure in the patent application.

[0045] This embodiment provides a method for manufacturing a multi-layer acrylic panel and its tooling. Firstly, the multi-layer acrylic panel manufacturing tool of this embodiment is introduced, such as Figure 1 to Figure 2 As shown, it is a mold 1, and the mold 1 includes: an upper mold 11, a lower mold 12, a first elastic ring 13, a fixing assembly 14, a clamping assembly 15, a second elastic ring 16 and an acrylic Laminate17. The upper mold 11 has an upper surface 111 and a lower surface 112 , the lower mold 12 has an upper surface 121 and a lower surface 122 , and the upper mold 11 and the lower mold 12 are made of glass material.

[0046] In this embodiment, the lower surface 112 of the upper mold 11 and the upper surface 121 of the lower mold 12, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com