Pump shaft sealing structure with wearing clearance compensation function

A technology of sealing structure and wear clearance, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, which can solve the problem of uneven butt joint contact surfaces of friction pairs, increase the gap between dynamic and static rings, and reduce mechanical seals. Service life and other issues, to achieve the effect of good sealing effect, simple adjustment and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

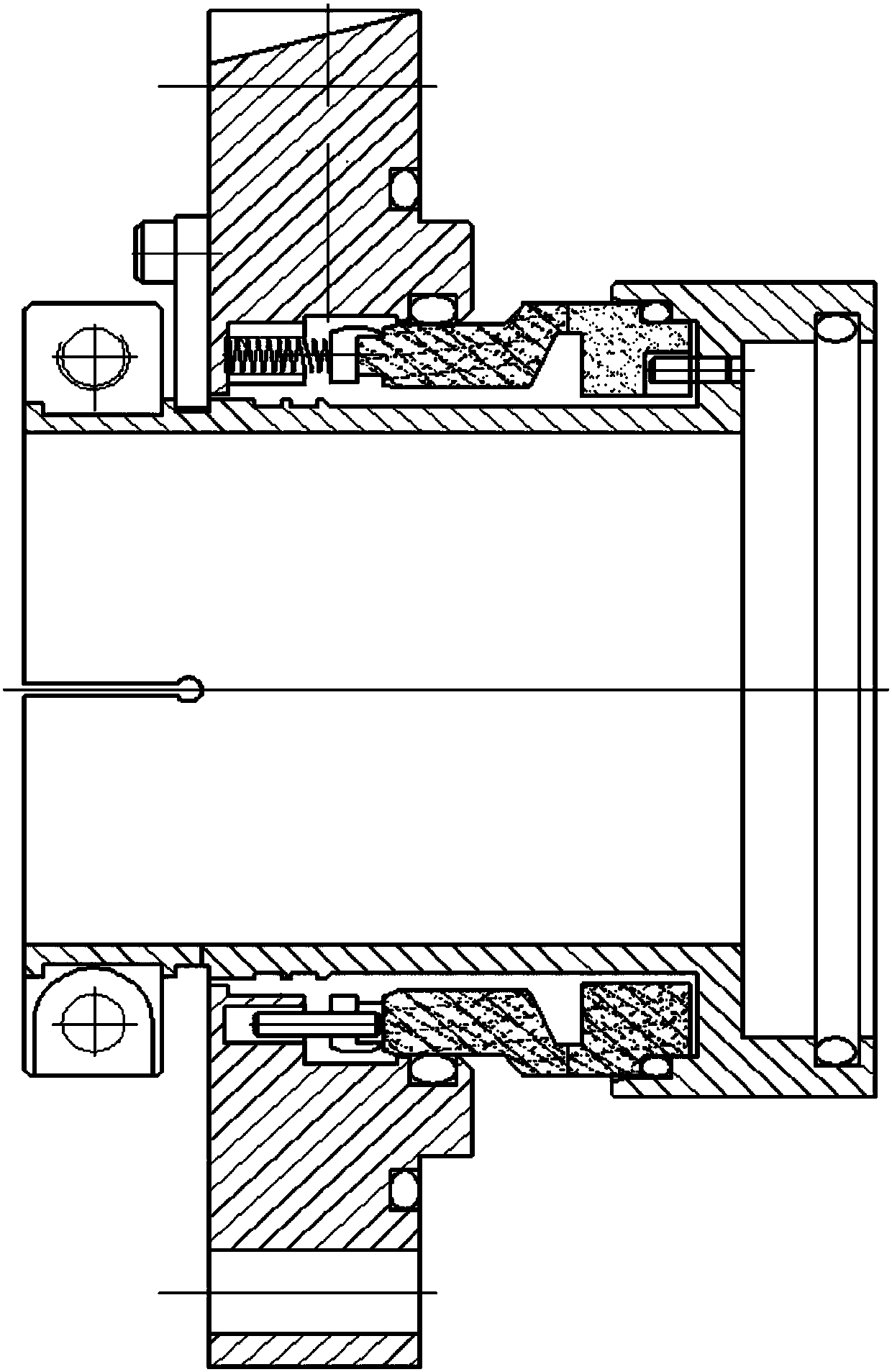

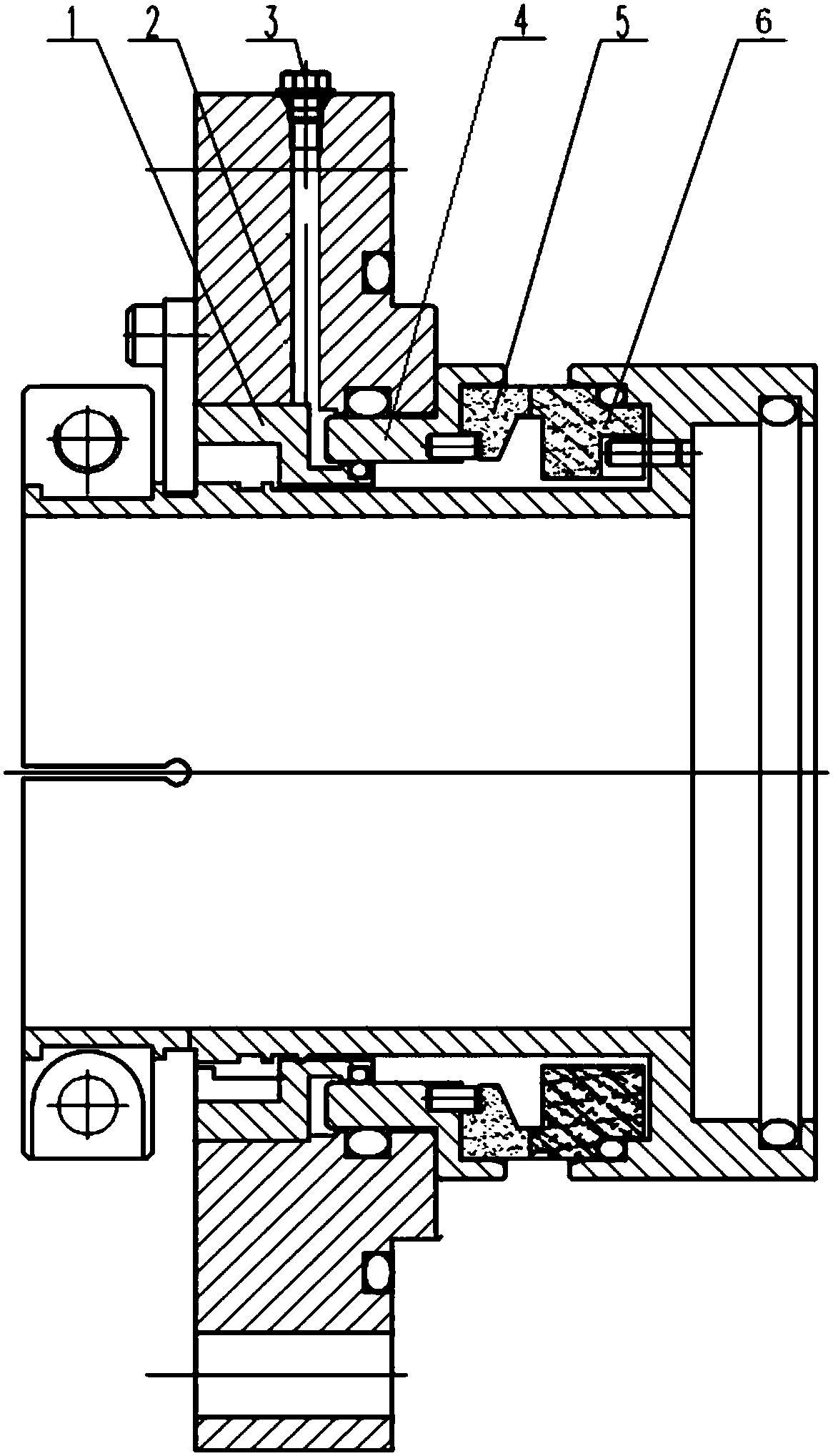

[0019] A pump shaft seal structure with wear clearance compensation of the present invention, such as figure 2 As shown, it includes pump cover body 2, tightening plug 3, front connecting ring 4, rear connecting ring 1, static ring friction pair 5, and moving ring friction pair 6;

[0020] The front end of the front connecting ring 4 is processed with a friction pair mounting seat, and the outer wall of the rear end of the front connecting ring 4 is processed with a stepped positioning platform;

[0021] The outer wall of the rear connecting ring 1 is a stepped cylindrical surface;

[0022] The dynamic ring friction pair 6 is fixed to the pump shaft sleeve, the static ring friction pair 5 is fixed in the friction pair mounting seat at the front end of the front connecting ring 4, the rear end of the front connecting ring 4 is inserted into the front end of the inner cavity of the pump cover body 2, and passes through the The stepped positioning platform on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com