Storage tank structure special for workpiece surface cleaning treatment

A technology of workpiece surface and placement groove, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the inconvenience of surface washing and cleaning of workpieces, poor washing effect, and single application of placement grooves, etc. problems, to achieve the effect of convenient washing and cleaning, improving ease of use, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

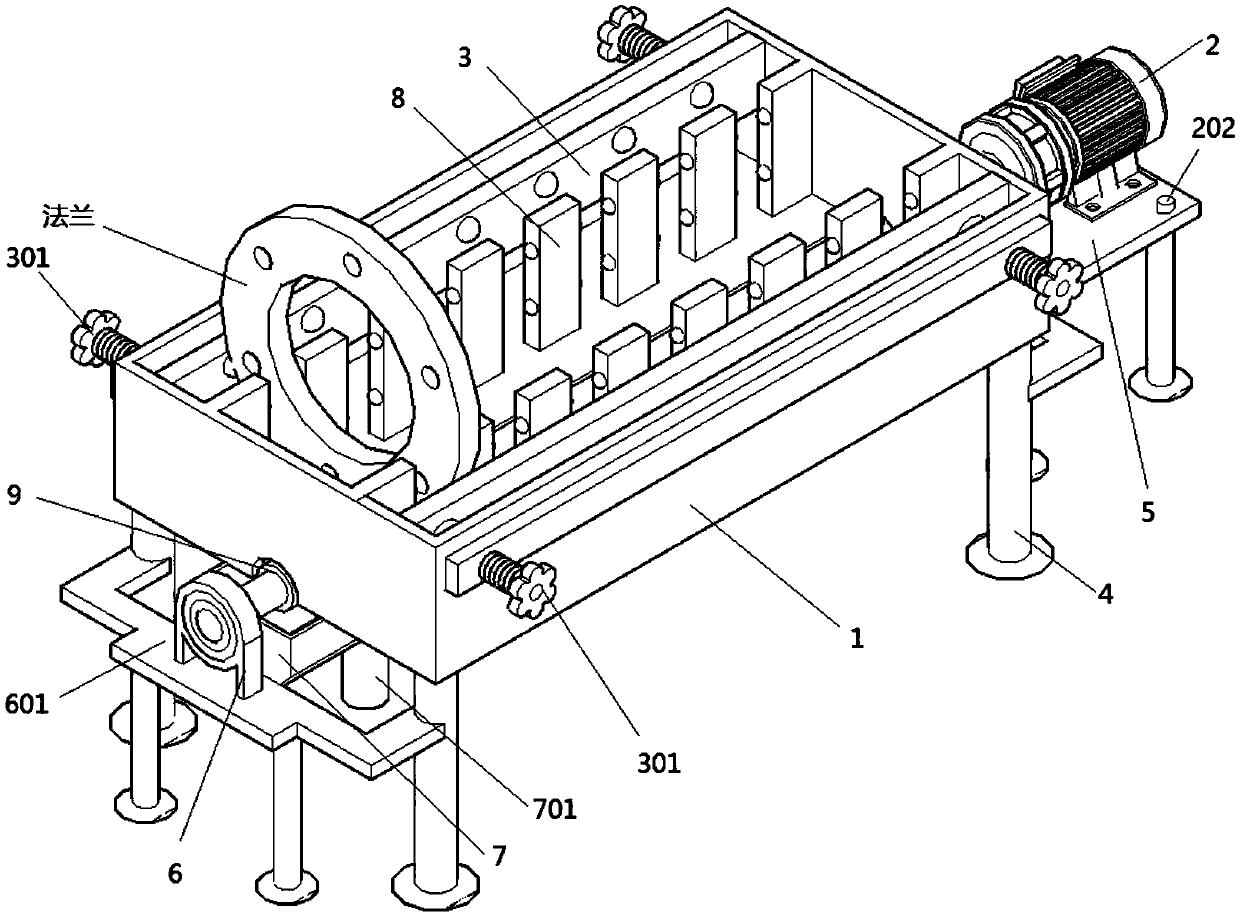

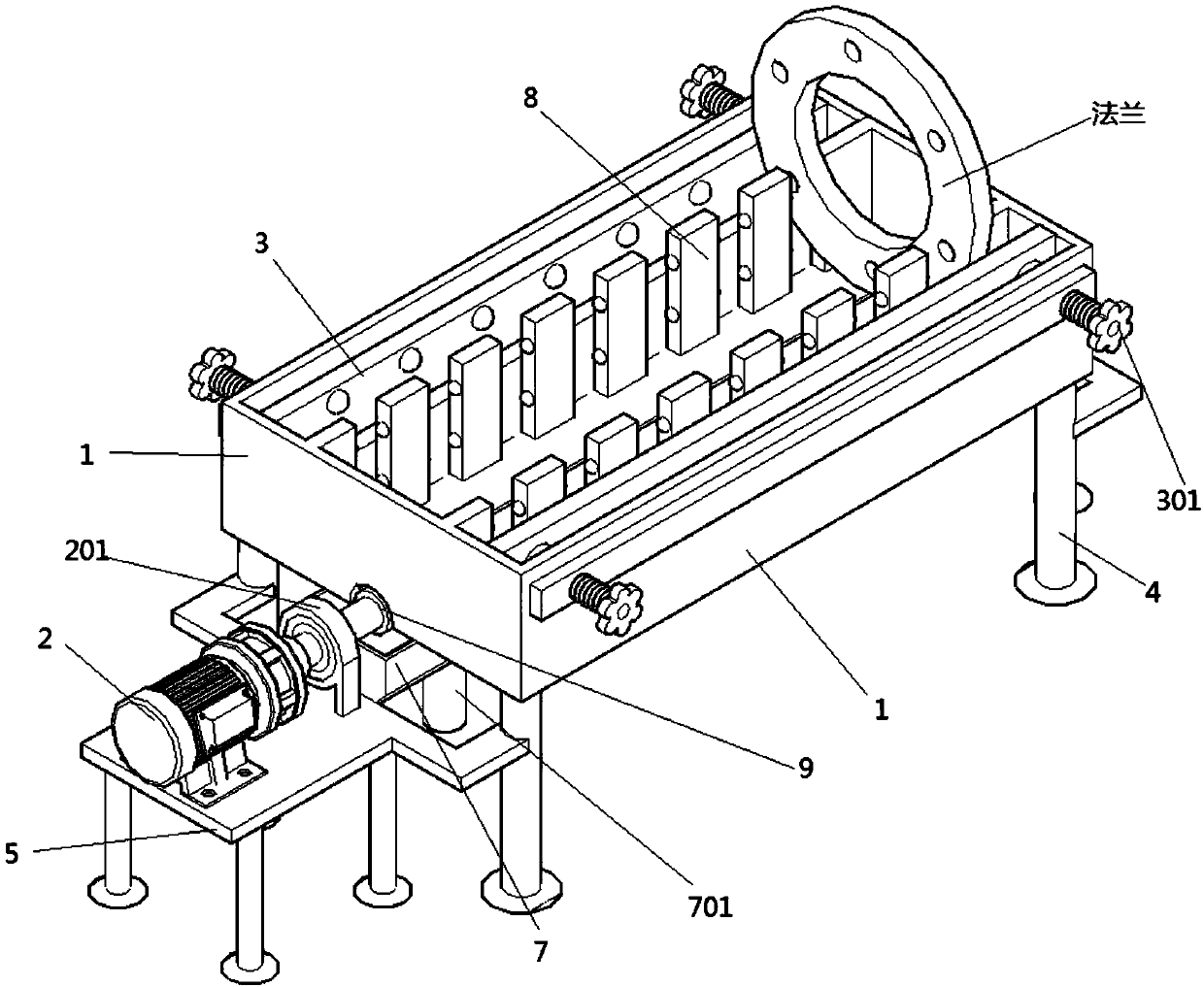

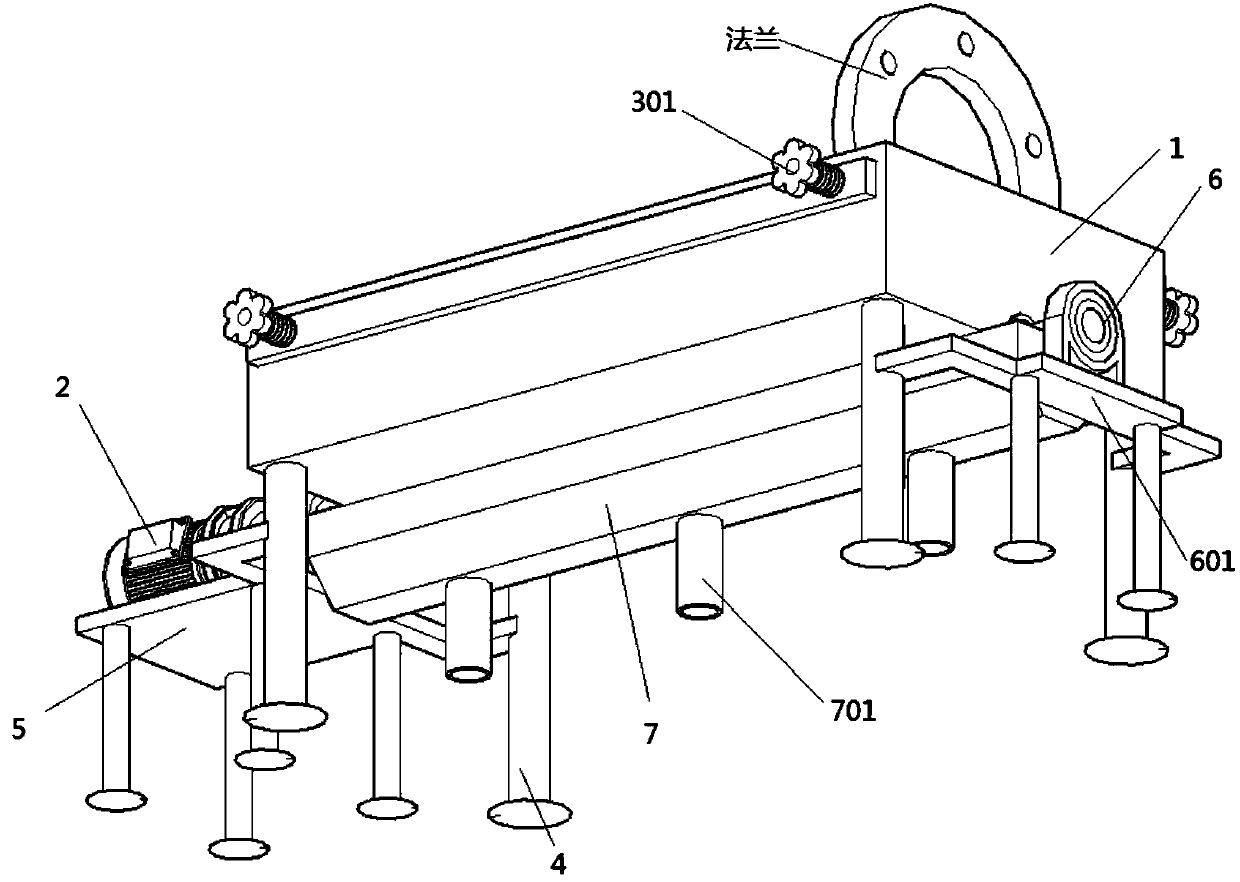

[0024] as attached figure 1 to attach Figure 4 Shown:

[0025] The present invention provides a placement tank structure dedicated to workpiece surface cleaning, including a placement tank body 1, a motor 2, a front bearing seat 201, a start button 202, a splint 3, a plum blossom adjustment bolt 301, a support rod 4, a motor bracket 5, and a rear Bearing seat 6, rear bearing seat support frame 601, water collection tank 7, leaking pipe 701, limit plate 8 and rubber roller 9, the bottom of the placement tank body 1 is symmetrically supported and provided with four support rods 4; the motor support The front end of 5 is horizontally welded with a double-headed bending connecting plate, and the left and right bending ends of the connecting plate are welded and fixed together with the two support rods 4 at the rear position; Motor 2, and a reducer is integrated on the motor 2; the top of the motor bracket 5 is also supported and welded with a front bearing seat 201, the former ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com