Scaling type universal socket spanner

A socket wrench and scaling technology, which is applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of metric wrench helplessness, inconvenience in life and production, etc., and achieve the effect of reducing quantity and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

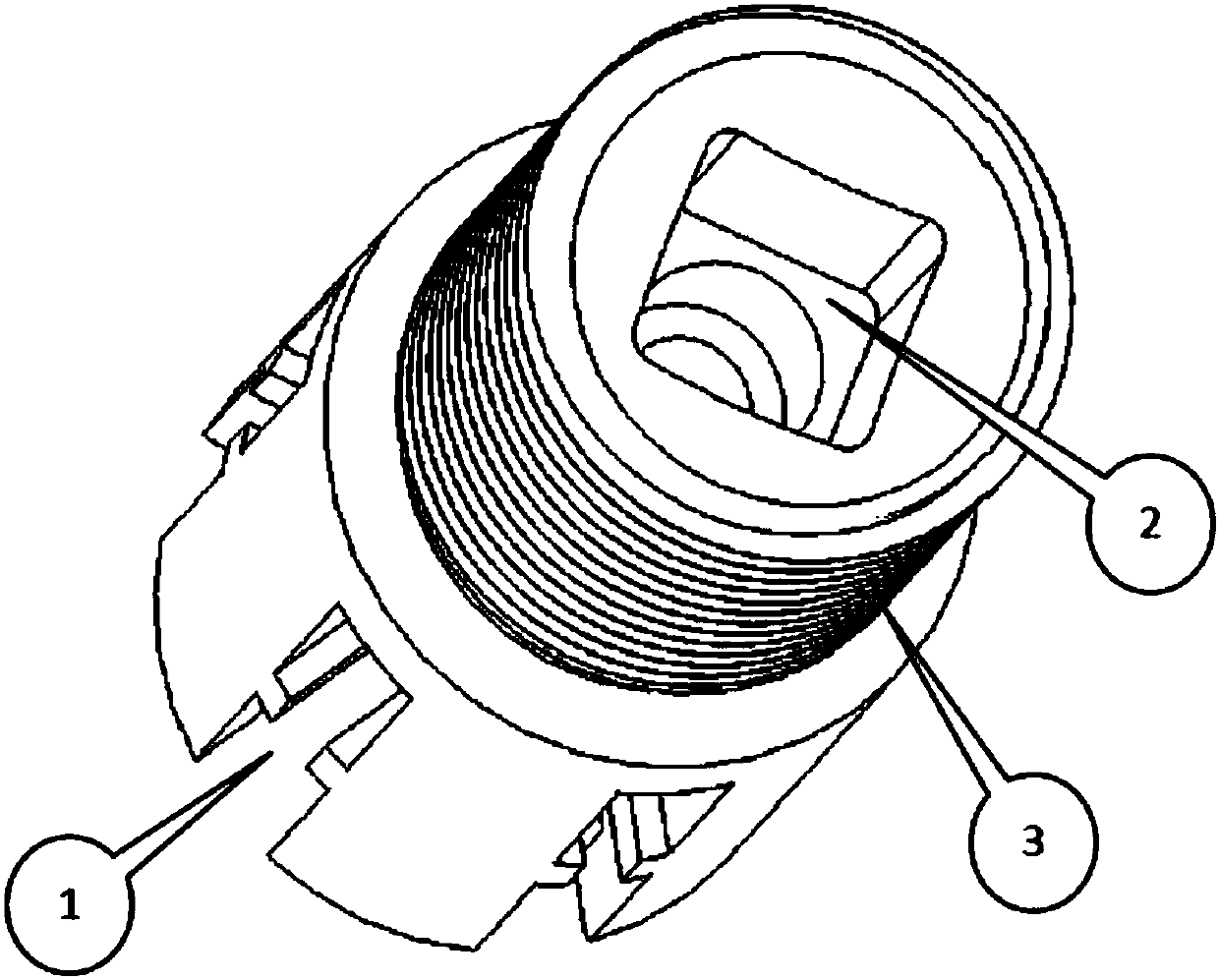

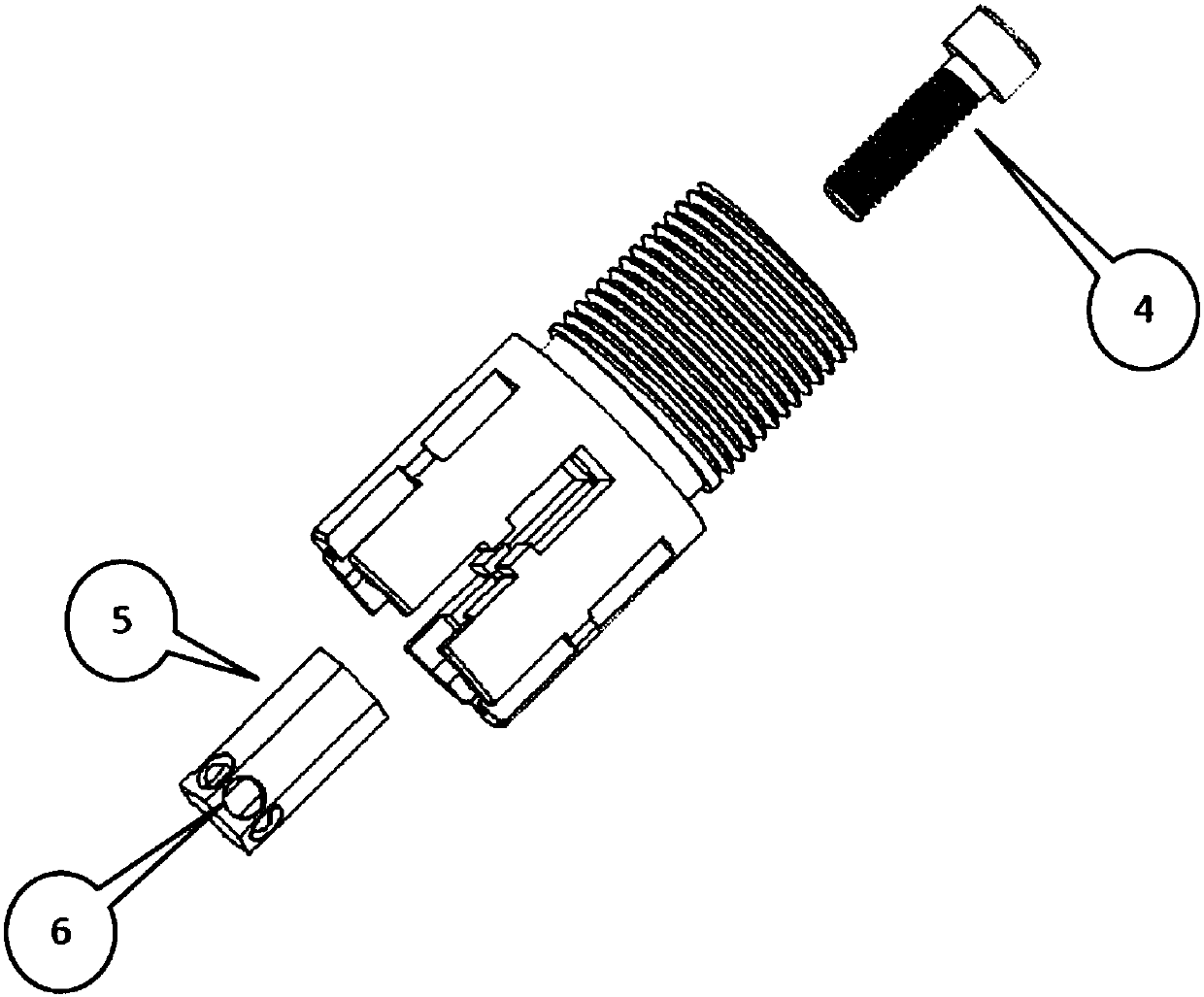

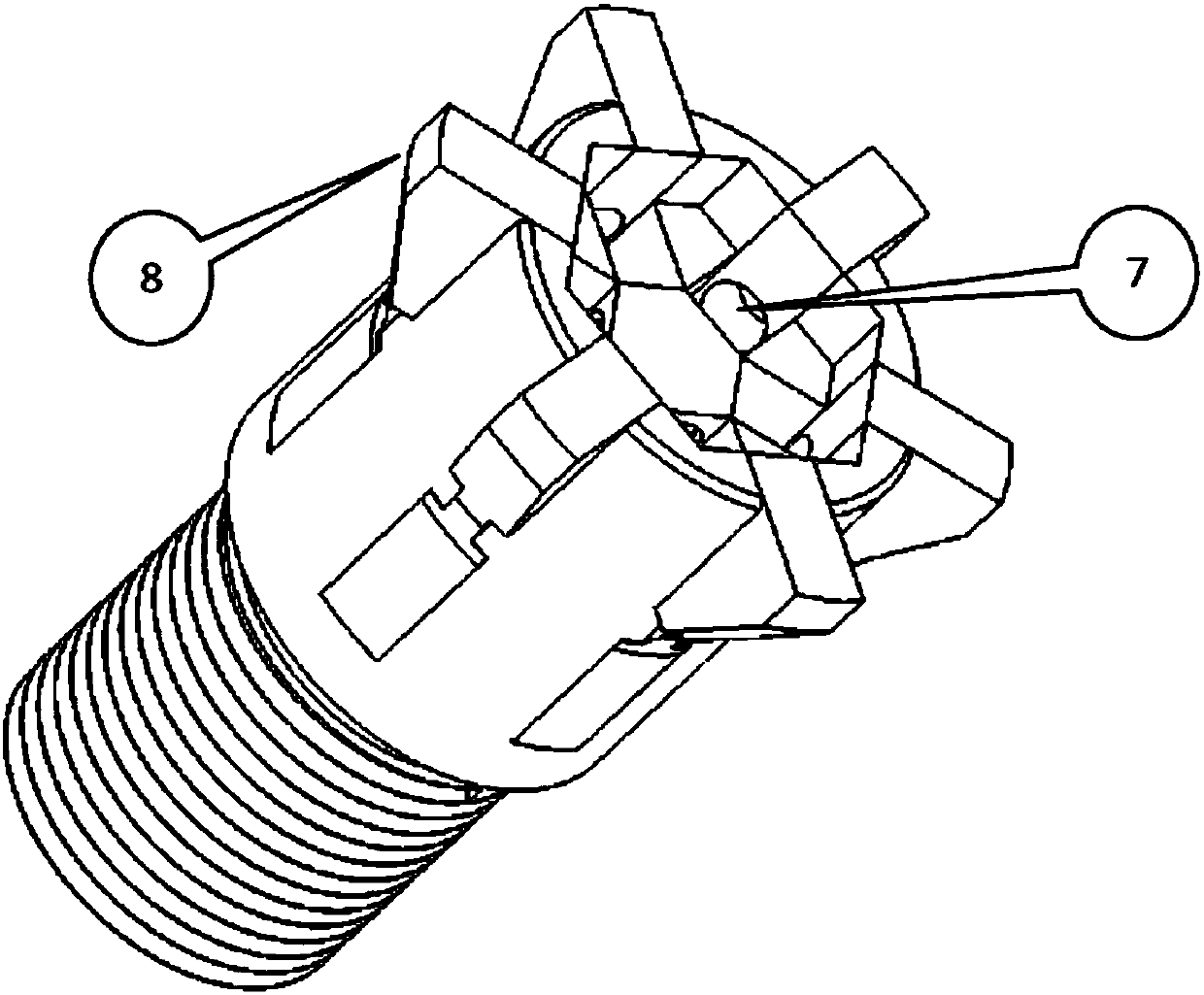

[0024] Such as Figure 1 to Figure 6 What is displayed is a new type of universal sleeve, showing the structure of each component and the relationship between them.

[0025] The sleeve includes an inner mandrel, the upper end of the mandrel is provided with an external thread 3, and the lower end is provided with six evenly distributed slider grooves 1 along the circumference, and the circumference of the slider groove 1 is evenly distributed with six radially movable Slide block 7, slide block 7 lower parts have a taper, a hole is arranged in the inner side of each slide block 7, a hexagonal mandrel 5 is assembled with a screw in the middle of the inner mandrel, and there are six equal parts at the bottom of the hexago...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com