Automatic dye weighing correction method and device, storage medium and computer equipment

A technology of automatic weighing and computer program, which is applied in the field of textile production and can solve problems such as large color deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

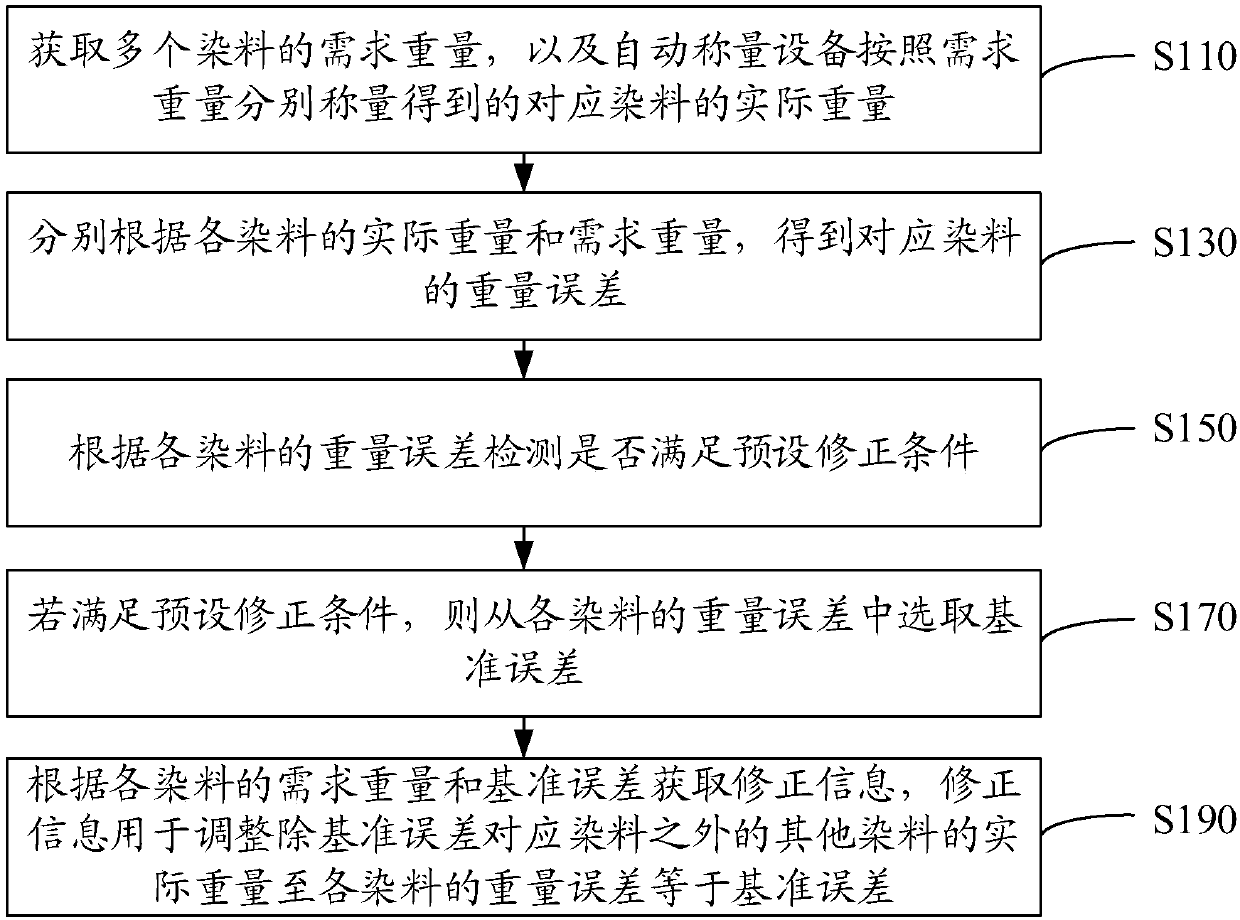

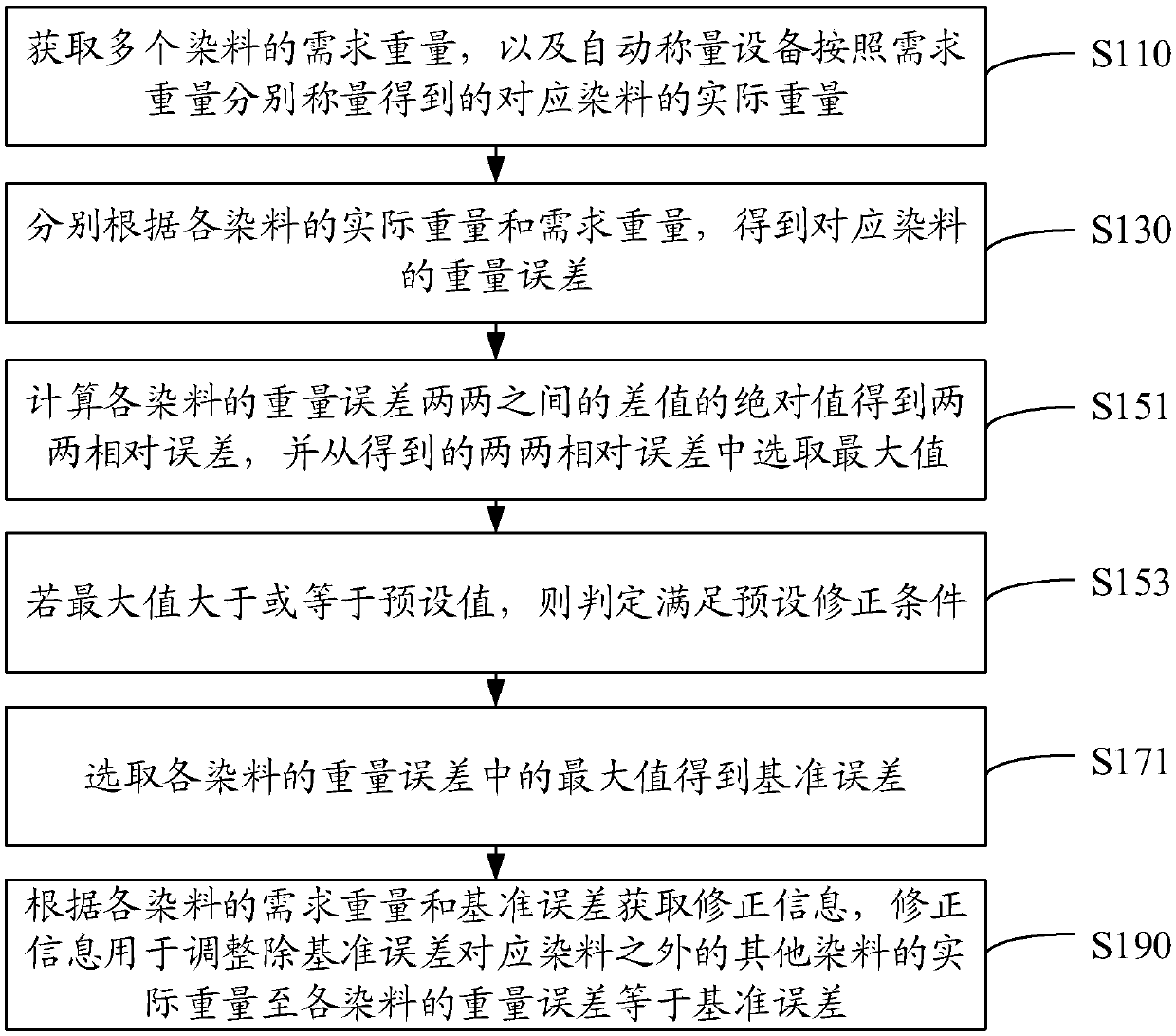

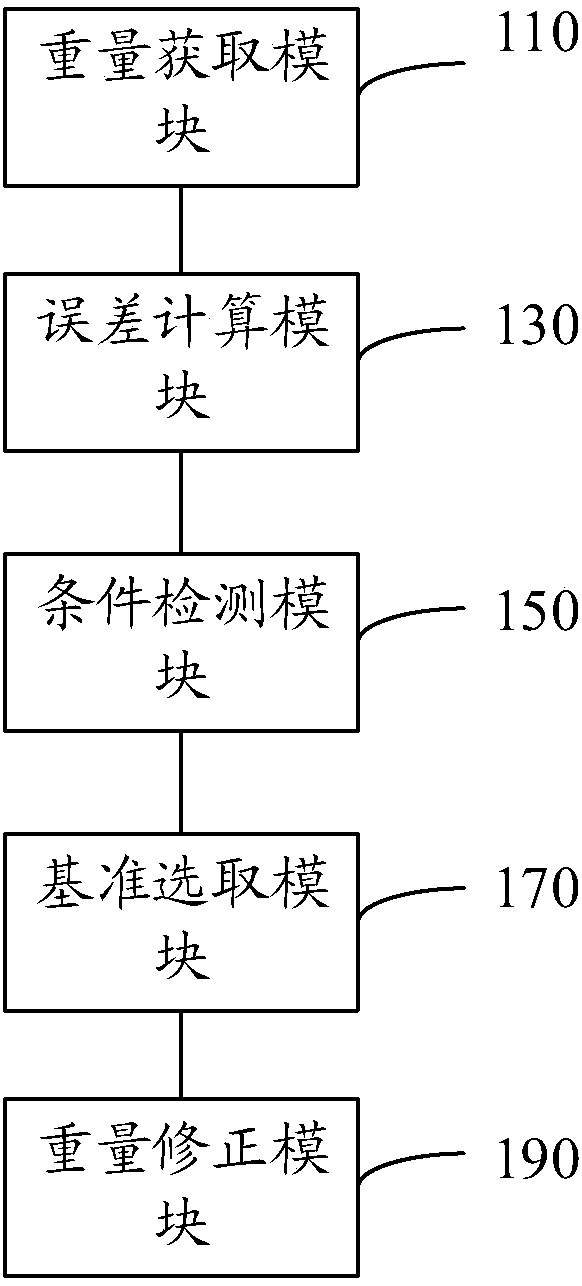

[0024] refer to figure 1 , the dye automatic weighing correction method in an embodiment, including step S110 to step S190.

[0025] S110: Acquire the required weights of multiple dyes, and the actual weights of the corresponding dyes obtained by weighing the required weights respectively by the automatic weighing device.

[0026] The required weight of the dye is the weight of the dye required by the plan; generally, the required dye and the required weight of each dye need to be determined according to the dyeing formula. The automatic weighing equipment weighs the corresponding dyes according to the required weight, and the weighing of multiple dyes in the same dyeing formula is the same batch weighing. Specifically, the required weight and the actual weight of the dye can be obtained by receiving information sent by an automatic weighing device, or by receiving information input manually.

[0027] S130: Obtain the weight error of the corresponding dye according to the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com