Motion loading device for hub detection and method thereof

The technology of a loading device and a propeller hub is applied in the field of motion loading devices for propeller hub detection, which can solve the problems of low production efficiency, single equipment function, and inability to perform integrated detection of multiple motion angles at the same time, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

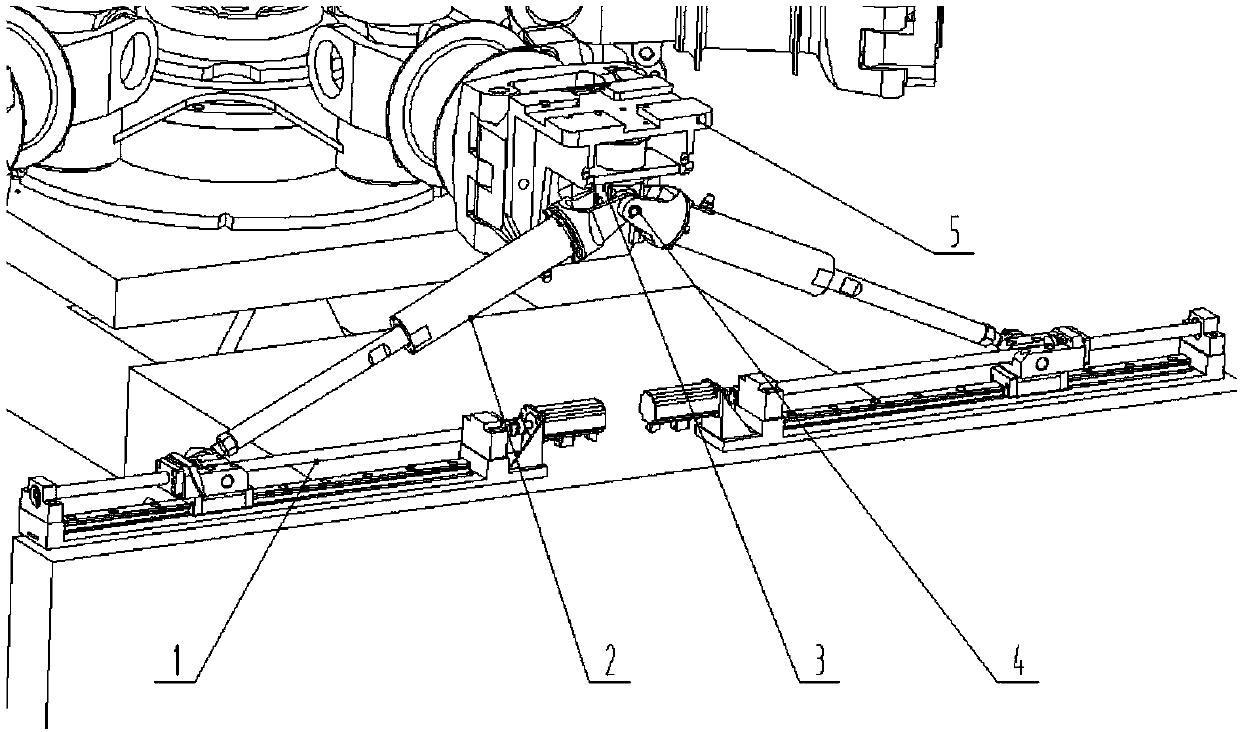

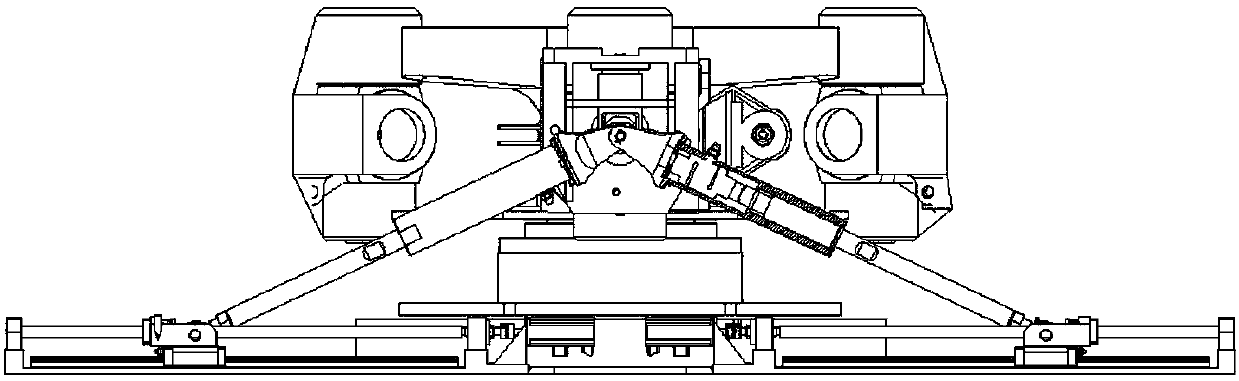

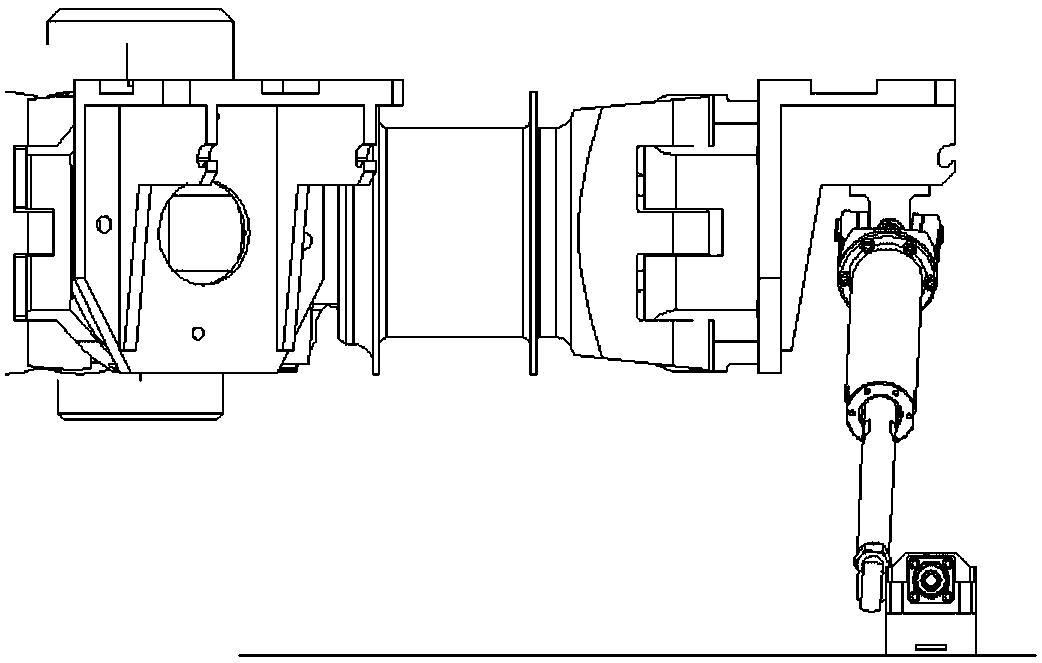

[0023] The present invention will be described in further detail below. see figure 1 , figure 2 , image 3 , the present invention includes designing and selecting a ball screw module 1, designing and manufacturing a mechanical connecting arm 2, designing and selecting a universal connector 3, designing and manufacturing a connecting pin shaft 4, and designing and manufacturing a hub connecting seat 5. The connection is carried out by connecting the pin shaft and the support hinge.

[0024] The ball screw module 1 includes a screw, a ball nut, a linear track, a slider, a bearing support seat, a base plate, and a driving motor. The block is guided by a linear track, the screw is supported by the bearing of the bearing support seat, the driving motor is connected to the screw, the rotation of the motor drives the screw to rotate, and the screw pair composed of the screw and the ball nut drives the slider to generate displacement. The blocks are displaced in opposite or oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com